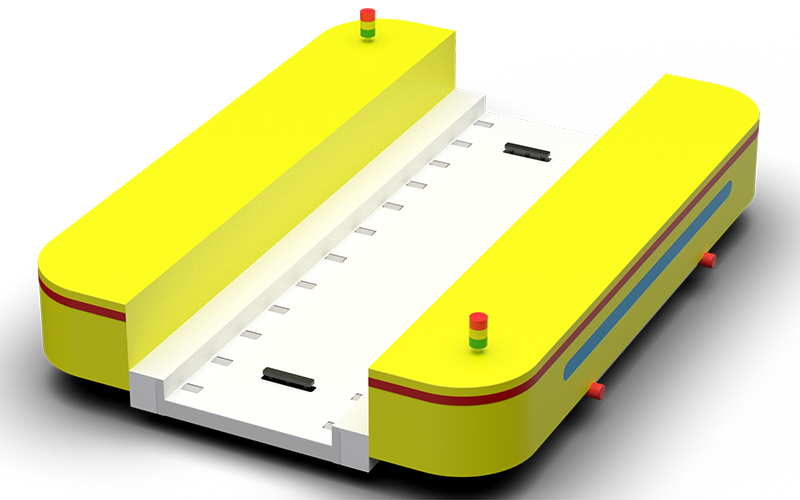

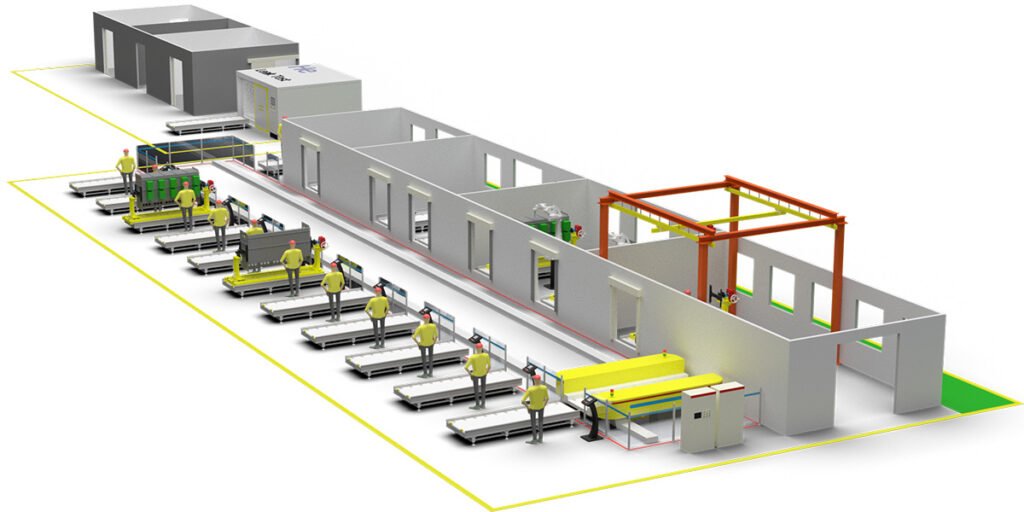

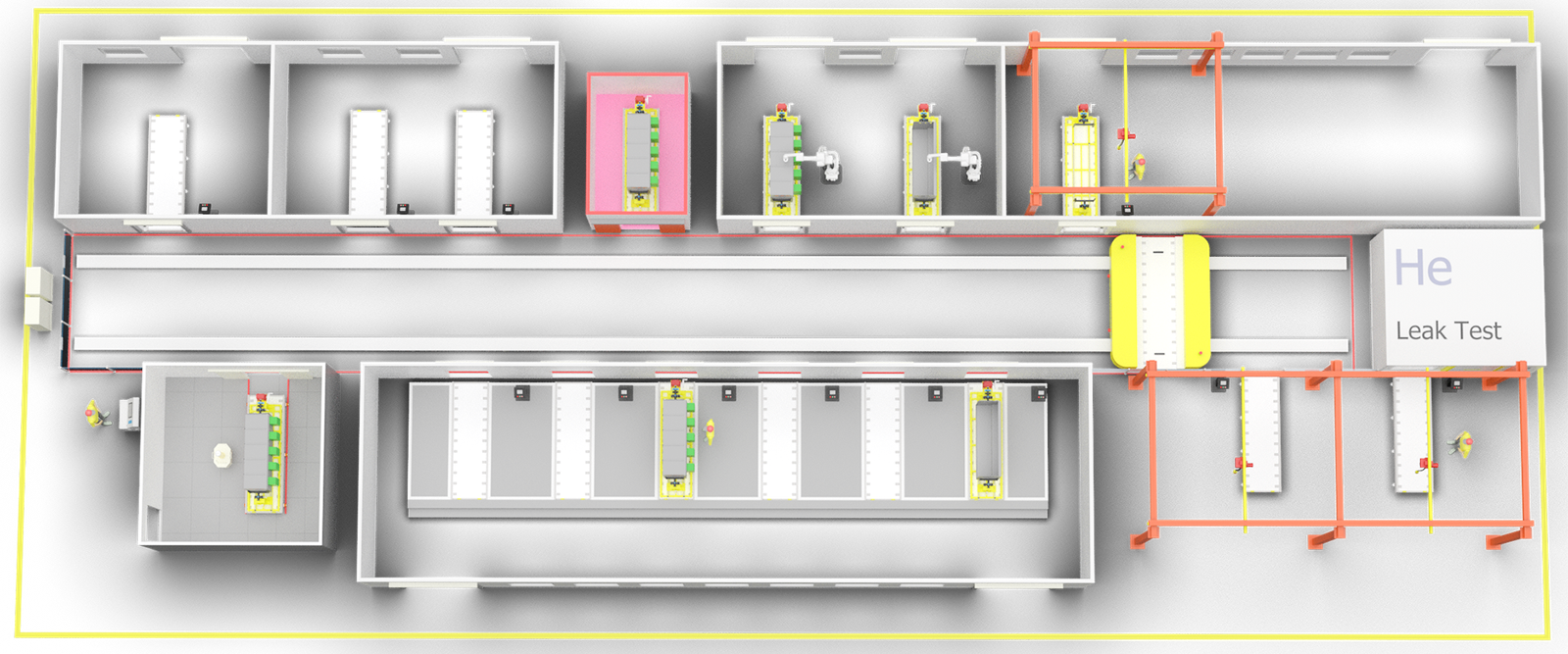

Automated assembly line equipment for assembling Ring Main Unit (RMU)

The assembly and production of Ring Main Unit (RMU) involves several steps, from the preparation of raw materials to the assembly and testing of the final product. The use of automated assembly line operation optimizes the process, which is more standardized than manual operation and improves the quality of product assembly.

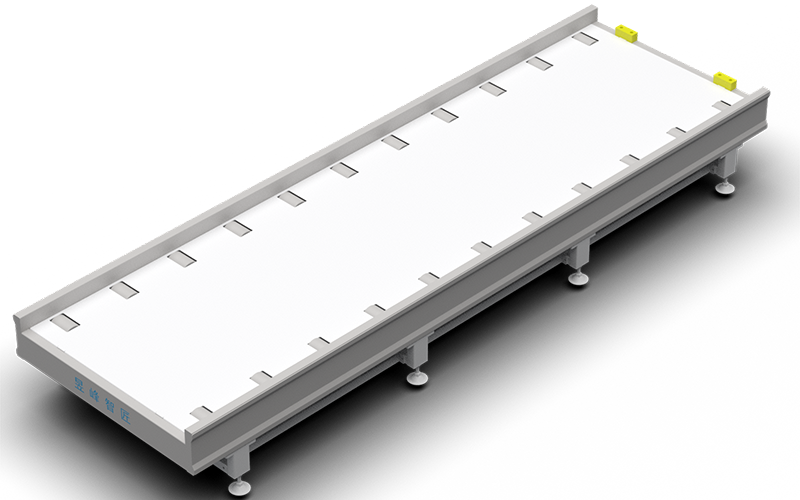

The assembly line of the ring main unit (RMU) includes assembly and welding of sheet metal shells; Installation of electrical components, such as load switches, fuses, circuit breakers, etc.; Break-in test; Mechanical performance adjustment; Secondary welding of sheet metal; Helium leak detection; Power frequency withstand voltage test; Partial discharge testing; Secondary wiring; Overall assembly, etc.

Modular design to meet the standardization of different production processes.

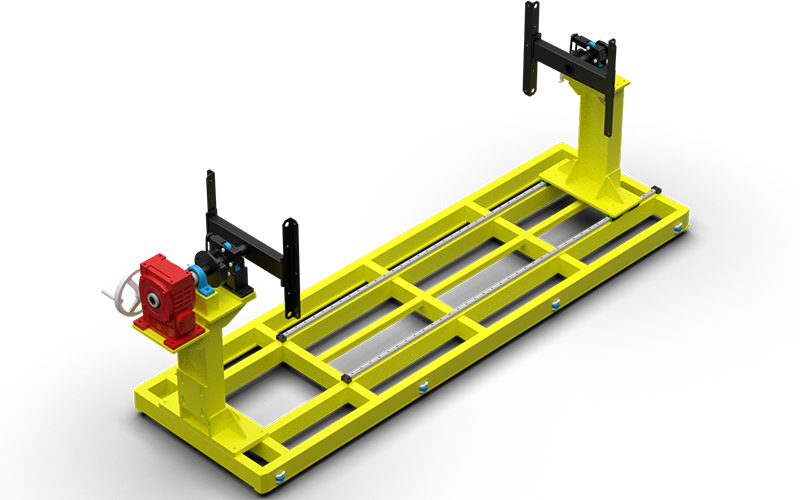

Robot welding ring main unit (RMU) workstation

- Adopting flexible fixture design, the robot welding workstation can adapt to the welding needs of different models and specifications of Ring Main Unit (RMU).

- The robot welding system can achieve precise welding trajectory and parameter control, ensuring welding quality.

- For the special material of stainless-steel gas insulated switchgear (GIS), cold arc welding technology is adopted to reduce the heat affected area during the welding process and improve welding quality.

- The robot system can achieve continuous welding and improve production efficiency.

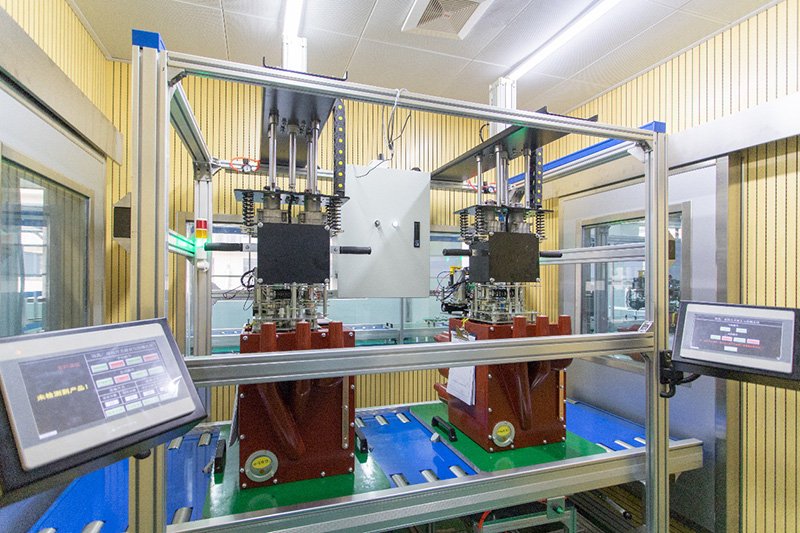

Ring main unit (RMU) testing equipment

- Running in test and mechanical performance adjustment of the ring main unit (RMU).

- Power frequency withstand voltage test to verify the stability of the product under power frequency operation.

- Partial discharge test and lightning strike test.

- Helium leak test to detect air tightness.

- Other series of tests conducted in accordance with production requirements.

- Test data integration with MES, SAP, etc.