Turnkey production line – VCB|GIS|RMU|PVB

Modular design of high-voltage electrical production equipment, GIS assembly line, VCB assembly line, RMU production line, PVB assembly line, switchgear production line, high-voltage current transformer assembly line.

Ring Main Unit (RMU) & Gas Insulated Switchgear (GIS) Assembly Line

The process of GIS (Gas Insulated Switchgear) assembly line mainly includes sheet metal component processing, component cleaning, welding, electrical component assembly, functional testing, gas filling, airtightness testing, and system debugging. These processes ensure the precise installation, sealing, and electrical performance of GIS equipment.

Vacuum Circuit Breakers (VCB) Assembly Line

The assembly line process for vacuum circuit breakers (VCB) begins with the preparation of raw materials, including copper, insulation components, and alloy contacts. Subsequently, the components enter the automated assembly line and are precisely assembled through production lines and fixed fixtures. After assembly, the product undergoes a running in test and mechanical characteristic adjustment. Continuing with a series of electrical tests, such as voltage withstand tests and operational tests, to verify its performance. Finally, qualified vacuum circuit breakers (VCB) undergo final inspection and packaging.

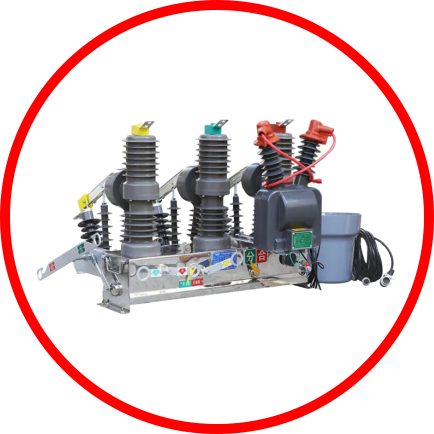

Pole-mounted Vacuum Circuit Breaker (PVB) Assembly Line

The production line of pole-mounted vacuum circuit breakers (PVB) usually includes the loading area, mechanism assembly area, waiting area, insulation cylinder assembly area, running in area, repair area, mechanical characteristic testing area, contact arm assembly area, and offline area. These areas are interconnected through automation equipment and control systems, ensuring the continuity and efficiency of the production process.

HV/MV/LV Switchgear Assembly Line

The process flow of the switchgear assembly line is a set of specialized processes for producing high-voltage switchgear. This process typically includes the following key steps: 1. Assembly sheet metal parts for switchgear; 2. Electrical installation of switchgear; 3. Functional testing of switchgear; 4. Cabinet connection test.

Dry type transformers assembly line

The dry type of transformer assembly line is an automated and intelligent production system specifically designed for assembling dry type transformers. It includes precise assembly of cores and windings, placement of insulating tubes, support and restraint of coils, and anti-loosening treatment of fasteners as key steps. After assembly, rigorous testing and quality inspection are conducted to ensure the performance and safety of the transformers.

Automated assembly conveyor line to meet the requirements of mass production.

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 | 31 | |||||

- Why a shielded enclosure is required for partial discharge testing of ring main units

- Why SF6 RMUs Must Undergo Gas-Tightness Testing and the Methods Used

- The role of power-frequency withstand voltage test in the production of ring main units

- The significance of a dust-free workshop for the assembly of ring main units

- What are the testing devices in the power switchgear production line?

- Intelligent Production System for Switchgear Cabinet Sheet Metal Processing with Robots