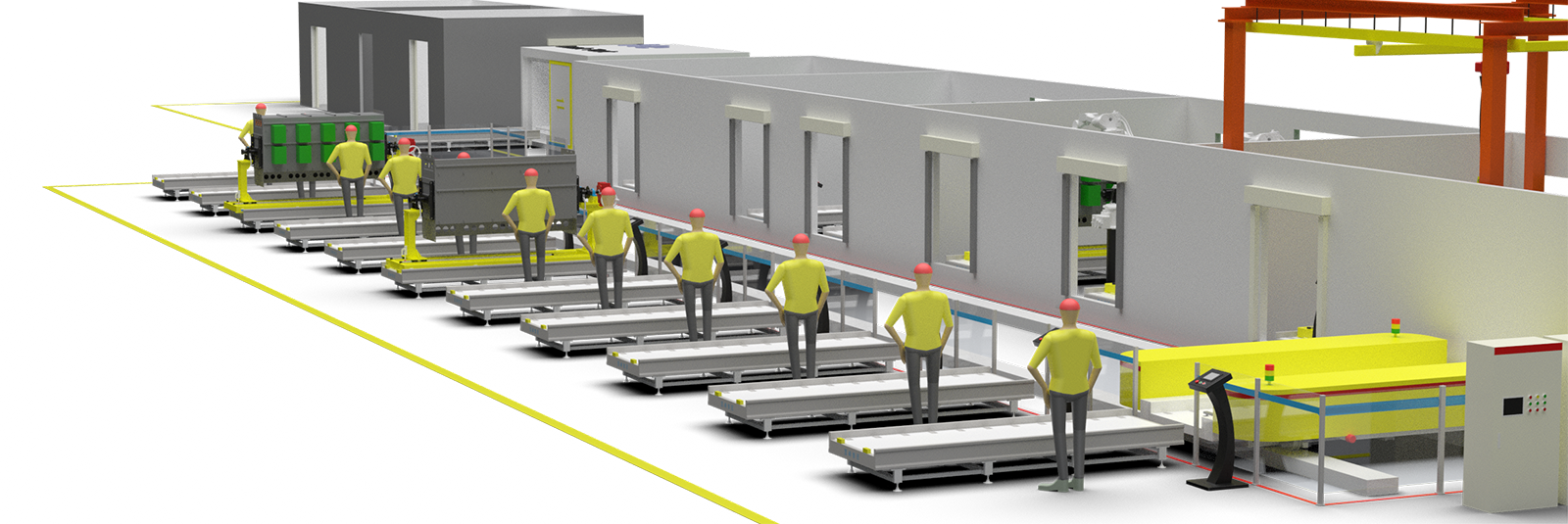

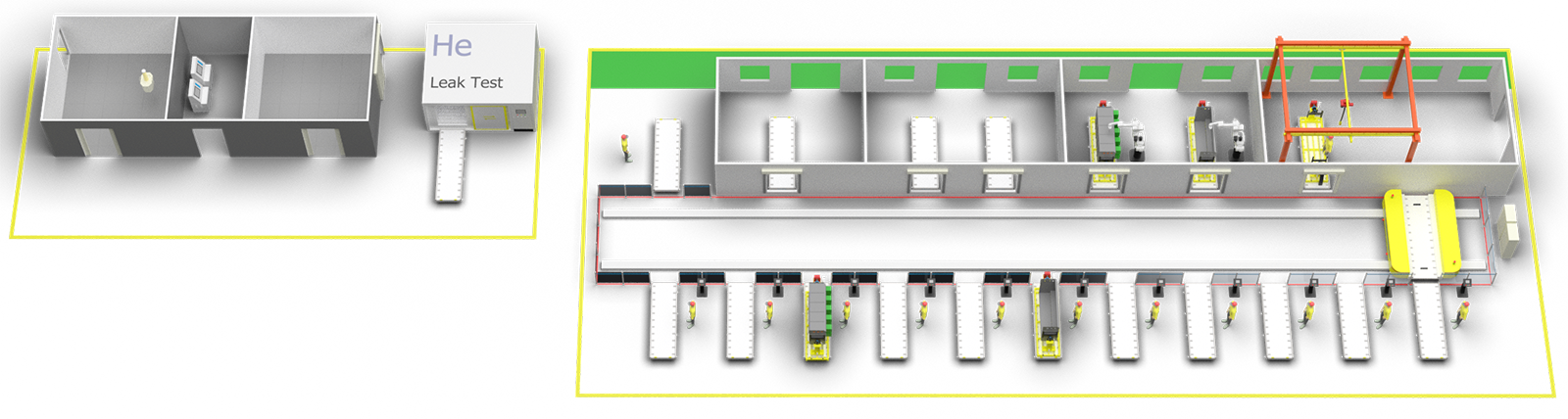

Gas Insulated Switchgear (GIS) & Ring Main Unit (RMU) Assembly Line

Automated equipment for mass assembly and production of Gas Insulated Switchgear Ring Main Unit (RMU), improving assembly efficiency and production quality, covering the required production processes.

The assembly line is suitable for:

Mass and standardized assembly production of gas insulated switchgear (GIS)

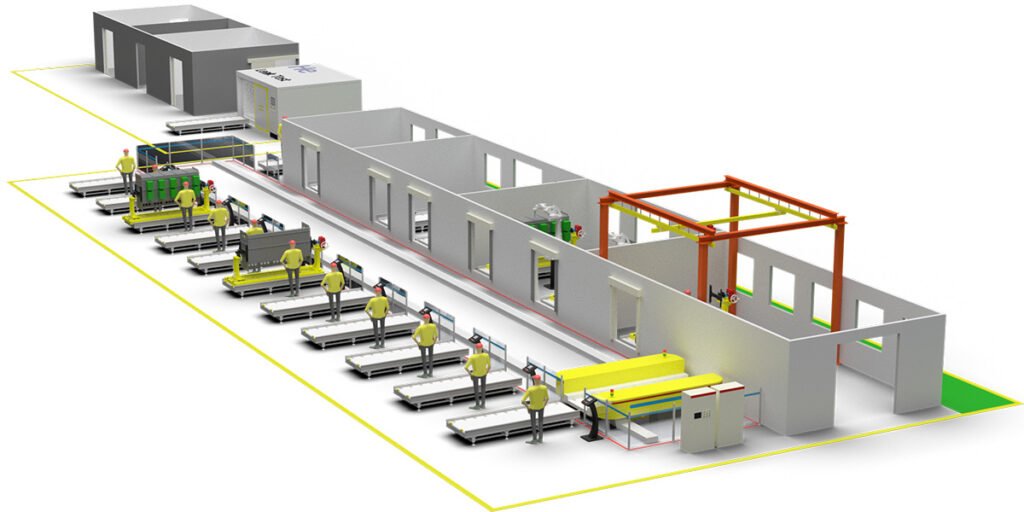

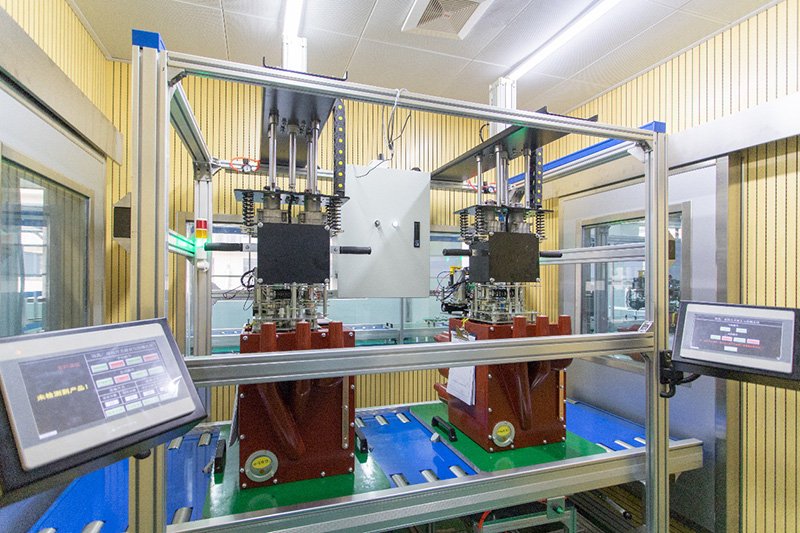

The Ring Main Unit (RMU) & gas insulated switchgear (GIS) production line is a highly automated manufacturing process that specializes in producing storage units for gas insulated switchgear (GIS). These switchgears are usually designed as hermetically sealed structures capable of being filled with insulating gases such as nitrogen or sulfur hexafluoride to improve the insulation and reliability of electrical equipment. The production line begins with the cutting and molding of raw materials, proceeds through welding, assembly, and then final inflation, sealing, and testing. The entire process involves sophisticated mechanical operations and electronic control systems to ensure that each gas insulated switchgear meets strict industry standards and performance requirements. Automated robots and computerized control systems play a key role in the entire production process, improving production efficiency and product quality.

Customized RMU GIS automated production lines for your production plant

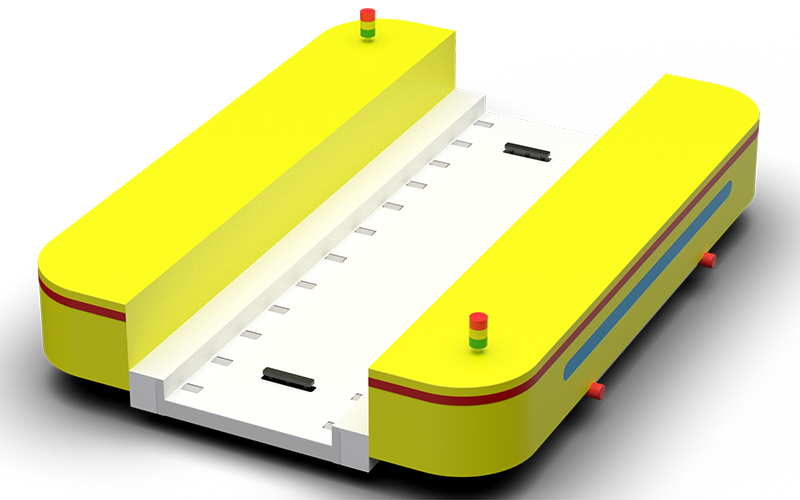

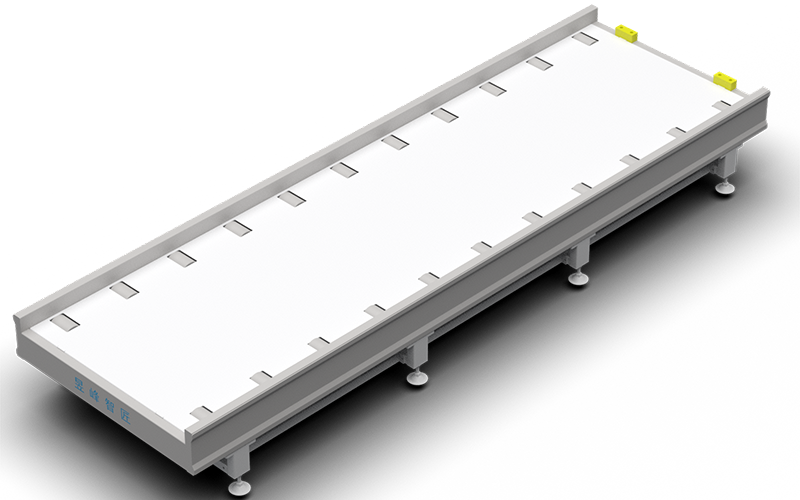

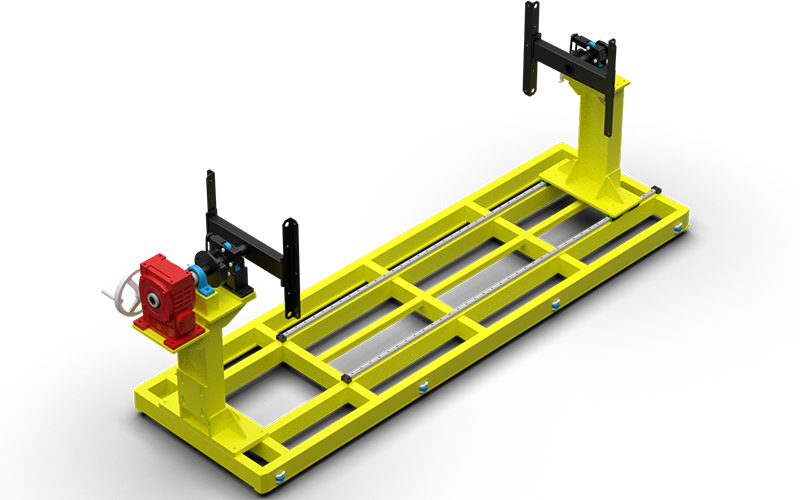

Modular design, provide efficient and stable equipment service.

Modular design of production lines has high flexibility and scalability, which can quickly adapt to product changes and market demands. It reduces maintenance costs by standardizing components and processes. In addition, modular design facilitates the integration of new technologies, improves production efficiency and quality control, while promoting innovation and continuous improvement. We have optimized the design of production supporting fixtures for GIS products based on their production characteristics, making them more efficient and convenient to use.