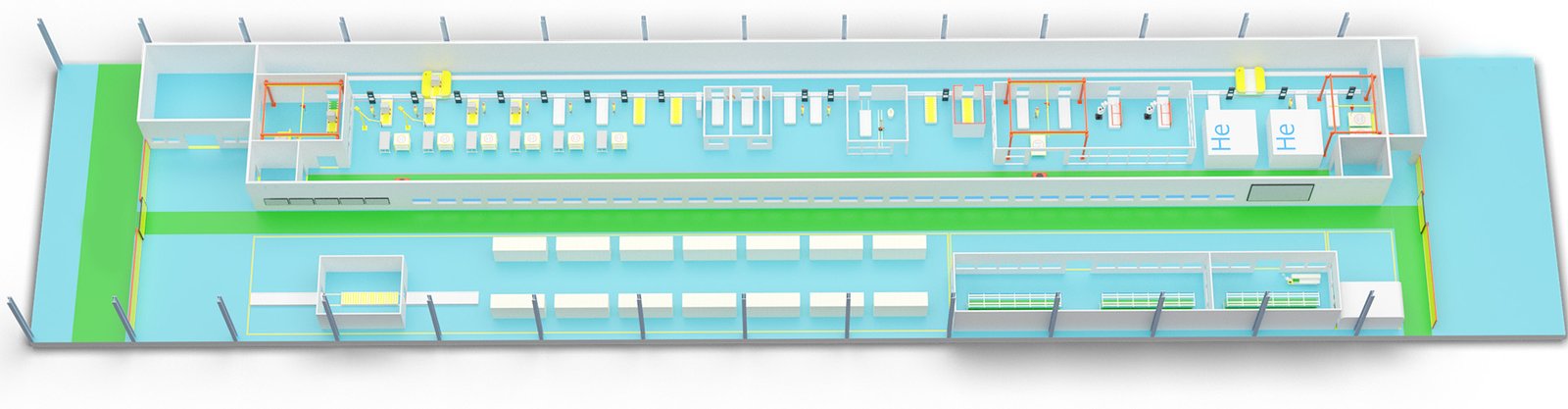

SF6-insulated ring main unit Production assembly line

SF6-insulated ring main units (RMUs) are a type of medium-voltage electrical combination equipment, with SF6-insulated load switches as the core components, capable of switching, connecting, and protecting power systems. Here is detailed information on the structure, assembly and testing process, process layout, and production line of SF6-insulated ring main units:

Structure

The structure of SF6-insulated ring main units typically includes:

- High-quality stainless steel casing to ensure airtightness.

- SF6 gas filled inside to provide insulation and arc extinguishing functions.

- Load switches, grounding switches, fuse insulating cylinders, and other switch moving parts and busbars, all sealed within the SF6-insulated gas box.

- Modular design, with various module combinations to achieve different bus configurations, forming an SF6-insulated ring main unit system.

Assembly and Testing Process

The assembly and testing process usually includes the following steps:

- Component Preparation: Prepare the required parts and components.

- Assembly: Assemble the various parts of the SF6-insulated ring main unit in a predetermined order and method.

- Performance Testing: Conduct power frequency withstand voltage tests, lightning impulse voltage tests, etc., on the assembled SF6-insulated ring main unit to ensure its performance meets standards.

- Gas Filling and Detection: Fill the gas box with SF6 gas and perform vacuum leak detection to ensure the gas is sealed properly.

- Quality Control: Strict quality control is carried out during the production process to ensure that each part and the final product meet the specified standards and performance requirements.

Process Layout and Production Line

The design of the process layout and production line aims to ensure the production efficiency and product quality of SF6-insulated ring main units. The production line usually includes the following stages:

- Design Phase: Engineers design the structure and functionality of the SF6-insulated ring main unit based on requirements.

- Material Preparation: Prepare the necessary materials, including SF6 gas, stainless steel or other metal materials, insulating materials, etc.

- Manufacturing Process: Use either a common box type or modular manufacturing process for SF6-insulated components.

- Welding and Assembly: Use advanced welding techniques, such as laser cutting and automatic welding manipulators, to ensure the sealing and airtightness of the SF6-insulated gas box.

- Testing and Inspection: After assembly is complete, various tests are conducted on the SF6-insulated ring main unit, including withstand voltage tests, short-circuit current tests, operational life tests, etc.

- Automation Solutions: Provide automation solutions to facilitate the construction of smart distribution networks for customers.

- Final Inspection and Packaging: Conduct final inspections before the product leaves the factory to ensure the product is defect-free and package it appropriately to protect it during transportation.

- Shipping and Installation: Ship the completed product to the customer’s designated location and provide installation services.

With the development of technology, the production of SF6-insulated ring main units increasingly focuses on the reliability, safety, and environmental adaptability of the products.