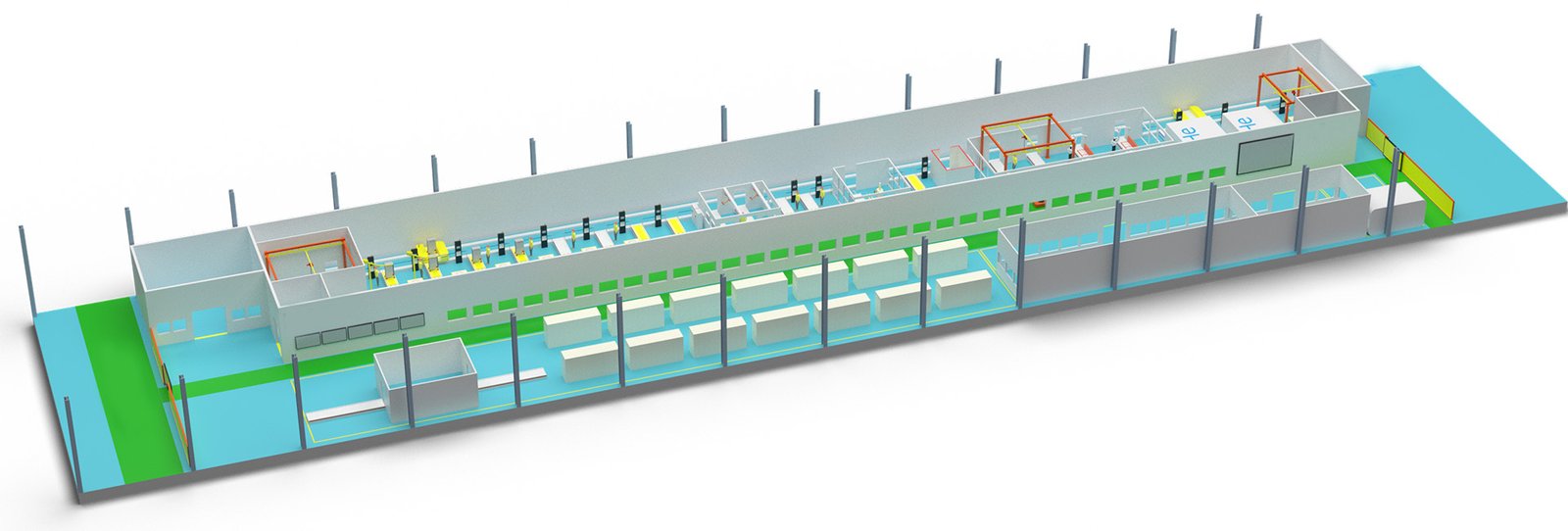

Air-Insulated Switchgear (AIS) Production line

Utilizing an assembly line for the production of Air-Insulated Switchgear (AIS) offers numerous significant benefits. Firstly, assembly line operations can significantly enhance production efficiency by automating and standardizing processes, reducing manual labor, and shortening production cycles. Secondly, the modular design of the assembly line allows for flexible adjustments to accommodate the production of different models and specifications of AIS equipment. Additionally, standardized quality control on the assembly line ensures that every product meets stringent quality standards, reducing the defect rate. At the same time, continuous operation on the assembly line minimizes material handling and storage time, reducing production costs. Lastly, assembly line production facilitates real-time monitoring and data collection, supporting continuous improvement and optimization of the production process. In summary, assembly line production not only improves production efficiency and product quality but also strengthens a company’s competitiveness in the market.

Air-insulated switchgear (AIS) structures and production testing processes are crucial to ensuring the quality and performance of the equipment. Here is the general information on air-insulated switchgear:

Structural Features

- Metal Enclosure: Air-insulated switchgear typically uses a metal-enclosed structure, which helps protect internal components from environmental influences and provides good electromagnetic compatibility.

- Air as Insulating Medium: The characteristic of air-insulated switchgear is the use of air as the insulating medium, which results in lower maintenance costs and environmental impact.

- Modular Design: Air-insulated switchgear adopts a modular design, allowing for flexible combinations of various functional units such as load switches, circuit breakers, and contactors, depending on different application requirements.

- Internal Arc Protection: Air-insulated switchgear is designed with internal arc protection features to safeguard operators in the event of an internal arc fault.

- Mechanical Interlocking Devices: The equipment is equipped with integrated central interlocking devices to ensure operational safety and prevent misoperation.

- Flexible Solutions: A variety of cabinet types are offered, including incoming and outgoing line cabinets, section cabinets, metering cabinets, and potential transformer (PT) cabinets, to meet different power grid configurations.

Production Testing Process

- Type Testing: A series of type tests are conducted during the design phase to verify the performance of the equipment under extreme conditions, including short-duration and peak withstand current tests, temperature rise tests, insulation tests, main switch opening and closing tests, and internal arc fault tests.

- Factory Testing: Each unit undergoes routine checks and tests before leaving the factory, including structural inspection, mechanical operation tests, power frequency withstand voltage tests, resistance measurement, and wiring correctness checks.

- Internal Arc Fault Protection Test: Internal arc fault protection tests are conducted to ensure that the equipment can protect the safety of operators in the event of an internal arc.

- Mechanical Operation Test: The main mechanical components of the equipment undergo operational life tests to ensure their reliability and durability.

- Temperature Rise and Main Circuit Resistance Measurement Test: Temperature rise tests ensure that the temperature rise of the equipment under rated current is within the specified range, while the main circuit resistance is measured to ensure compliance with standards.

- Gas Chamber Pressure Endurance Test: If the equipment includes gas chambers, pressure endurance tests are conducted to ensure the structural integrity.

- Seal Test: The sealing performance of the equipment is tested to ensure reliability under various environmental conditions.

Through these rigorous production testing processes, air-insulated switchgear can meet high standards of performance and safety requirements.