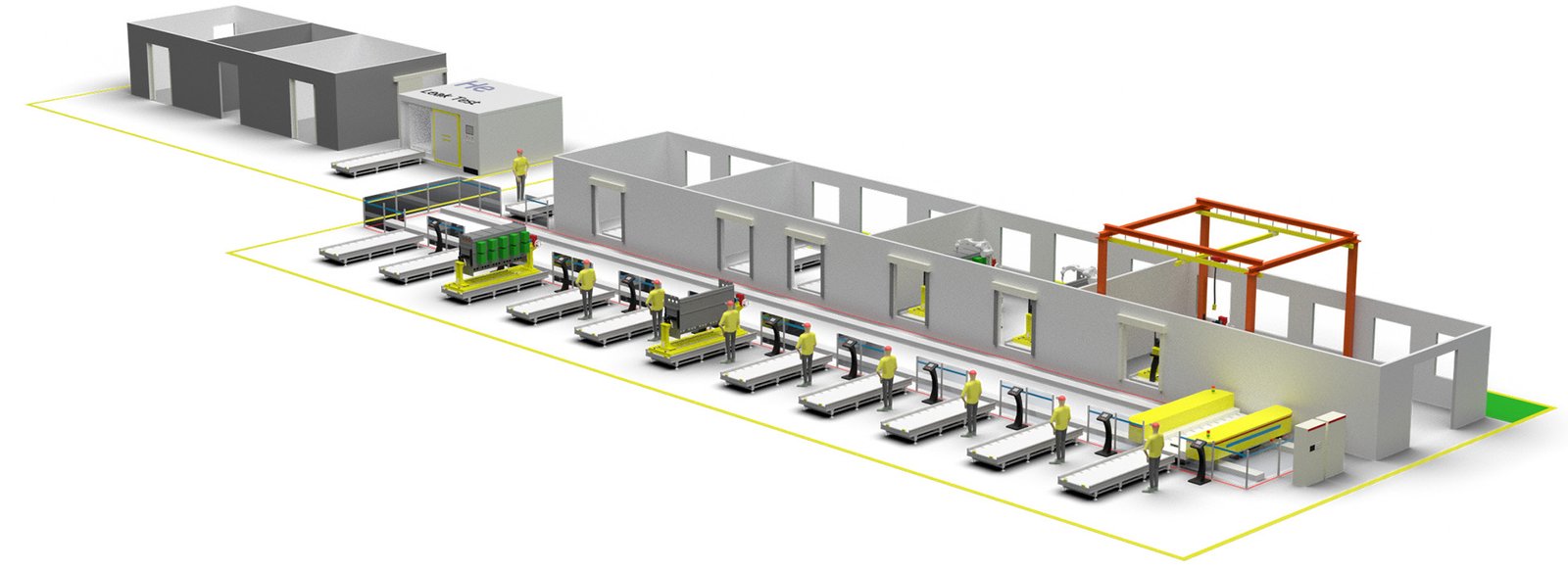

The assembly and testing process of a ring main unit (RMU) assembly line involves precise handling of key components such as switchgear, fuses, operating mechanisms, and cable compartments. Each part is meticulously assembled to ensure safety and reliability, with special attention to the switchgear compartment’s sealing and the fuse’s rapid interrupt capability. After assembly, the RMU undergoes rigorous testing, including insulation resistance measurement, current carrying capacity checks, and operational tests to confirm its functionality and adherence to safety standards before being deemed ready for deployment.

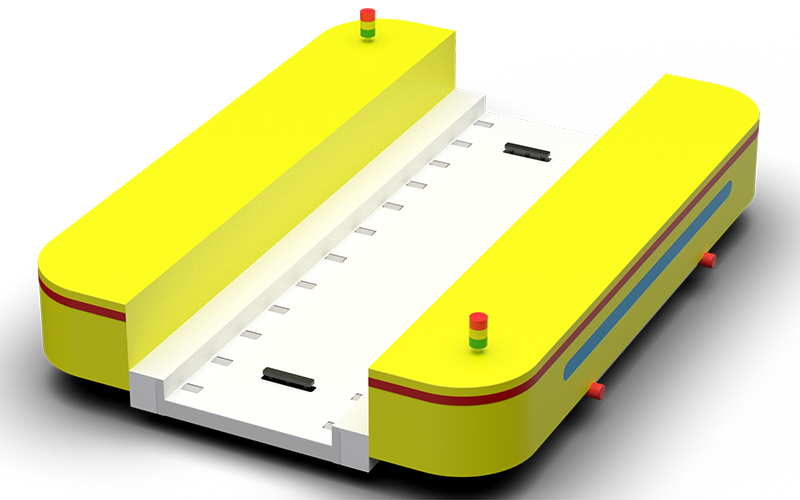

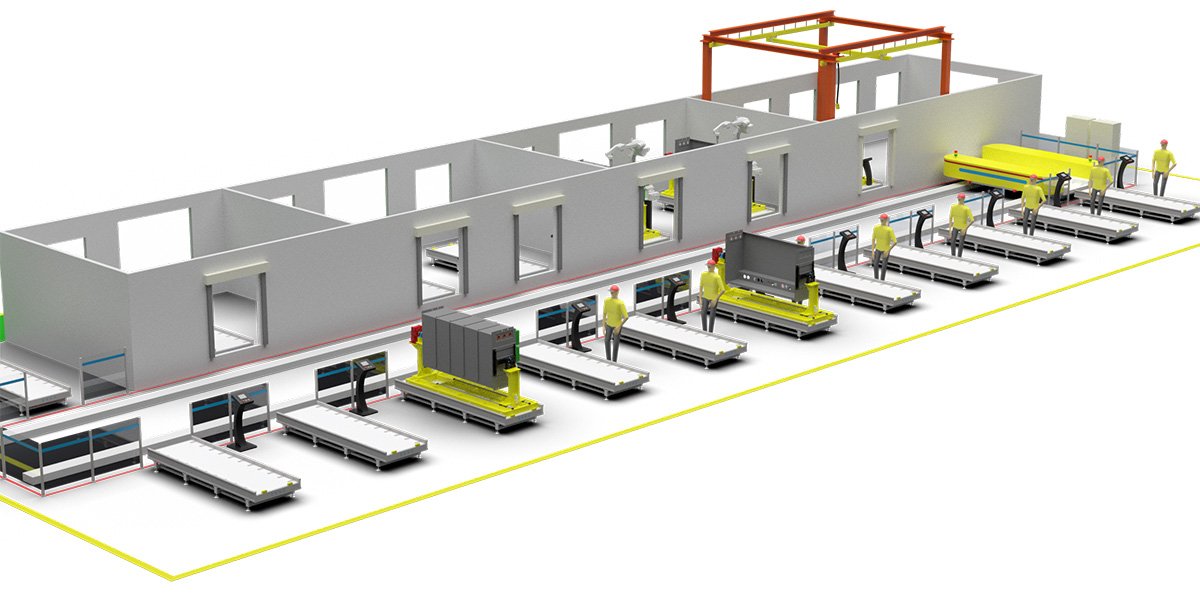

Ring Main Unit (RMU) Assembly line Modular equipment

Ring Main Unit (RMU) Assembly & Production processing

- Switchgear Compartment: The switchgear compartment is the core of the RMU, containing various functional circuits such as earthing switches and load switches, along with the interconnecting busbars, all sealed within a metal casing. The assembly process for the switchgear compartment requires precision to ensure that all electrical connections are safe and reliable.

- Fuse Compartment: The fuse compartment, together with the load switch compartment, forms the transformer protection circuit. High-voltage current-limiting fuses are typically housed within an epoxy-encapsulated insulating shell. During assembly, it is crucial to ensure that the fuses can interrupt the circuit rapidly in the event of an overload or short circuit, protecting the equipment from damage.

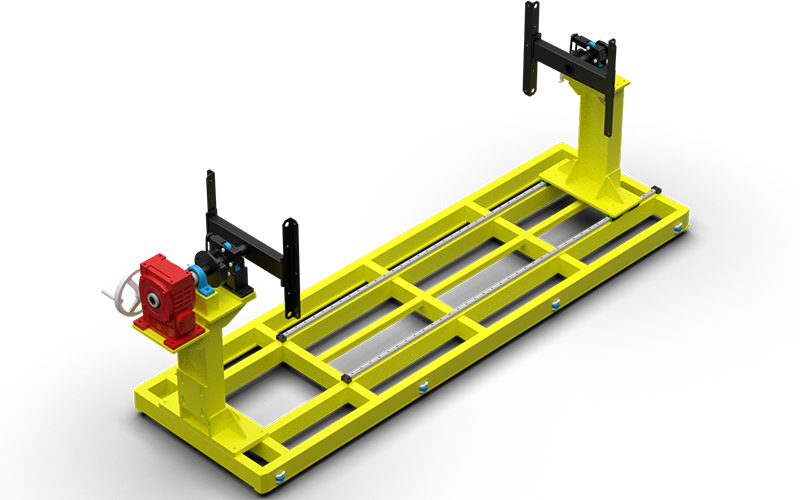

- Operating Mechanism Compartment: The operating mechanism compartment is located at the front of the RMU and contains manual or electric spring operating mechanisms for the load switches and earthing switches. The assembly of the operating mechanism compartment needs to ensure the flexibility and accuracy of operations, as well as interlocking devices to prevent mis operation.

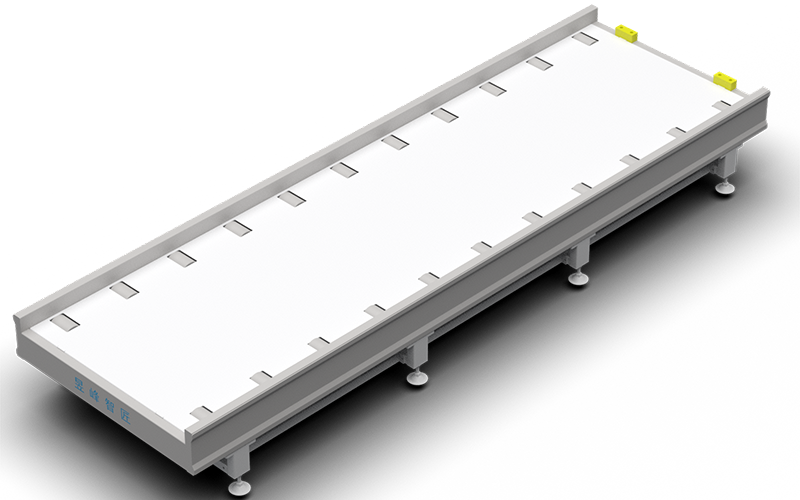

- Cable Compartment (Base Frame): The cable compartment is the foundational part of the RMU, designed to accommodate the cable connections for incoming and outgoing lines. The assembly of the cable compartment requires ensuring that cables are securely fixed and connected, while also facilitating easy maintenance and repair.

- Other Components: In addition to the main components, an RMU may also include accessories such as microprocessor-based protection and display units, live indicators, fault indicators, and temperature and humidity controllers. The assembly craftsmanship for these components also needs to be carried out strictly according to technical specifications to ensure the overall performance and safety of the RMU.