Custom production lines plant requirements of RMU VCB GIS

Custom production lines are designed to meet specific product or production needs, and they can be individually adjusted according to the specific requirements of the enterprise. Here are some key points to consider when looking at custom production lines from different perspectives:

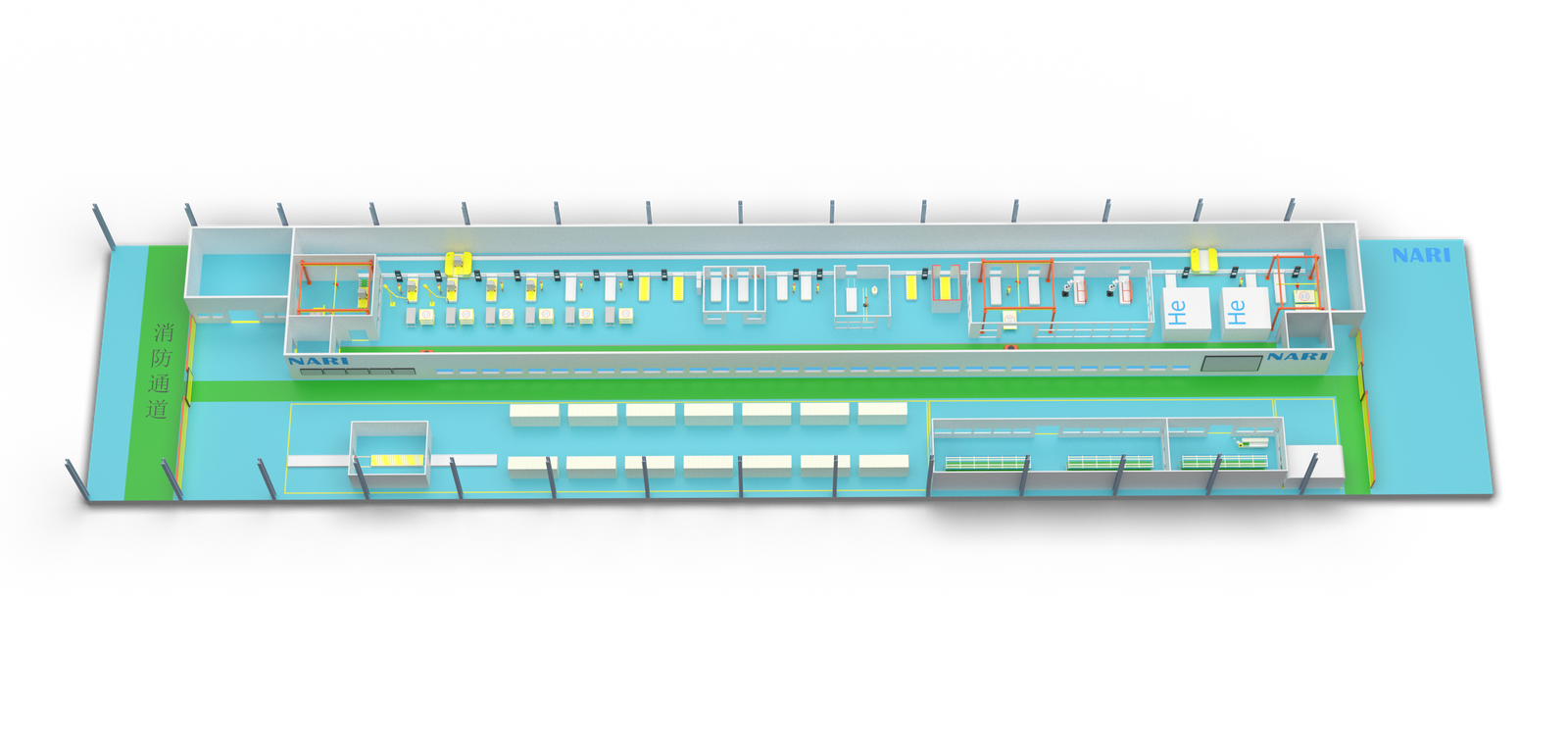

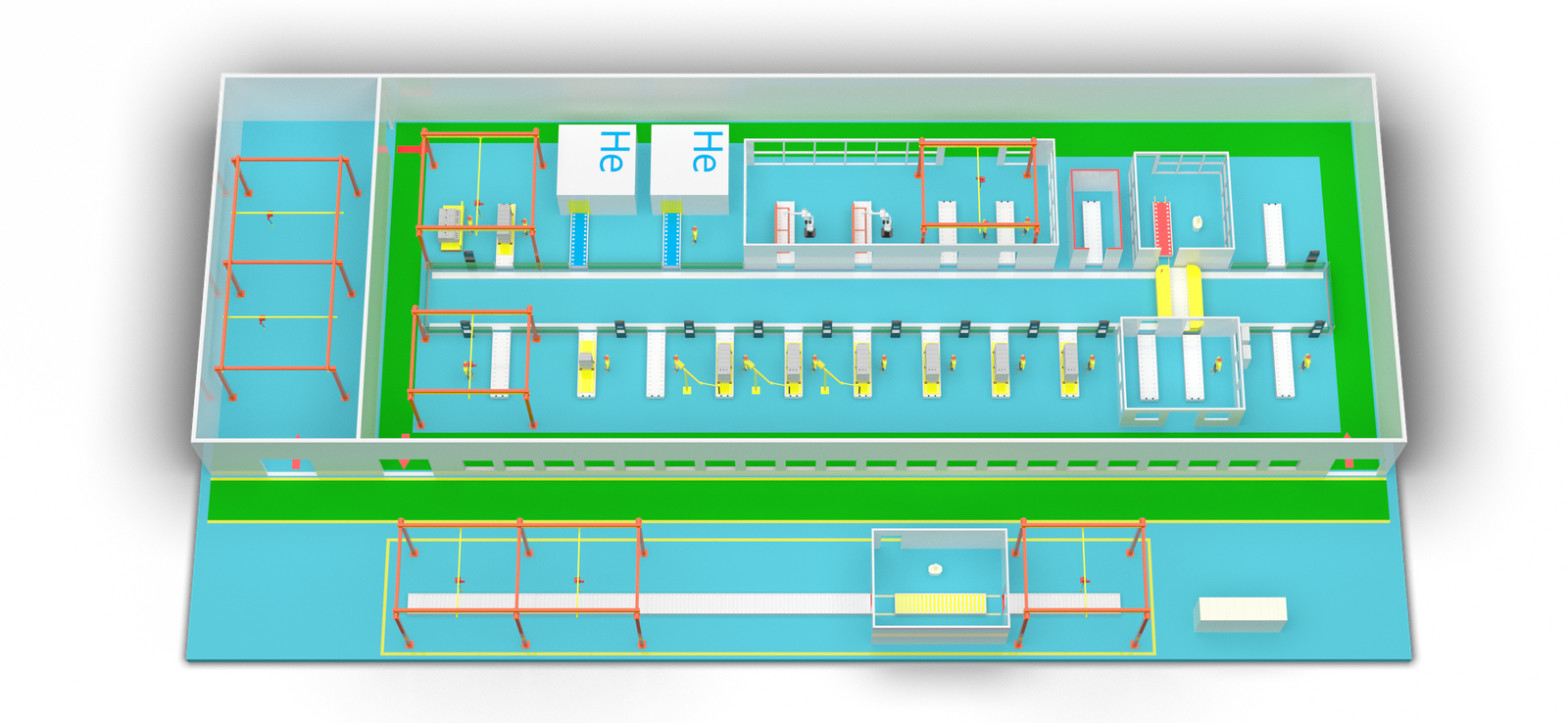

- Workshop Area:

- Custom production lines need to be designed according to the actual area of the workshop to ensure that the layout of the production line is both rational and efficient.

- The height, width, and length of the workshop will affect the layout of the production line and the selection of equipment.

- Planned Production Capacity:

- The planned production capacity of a custom production line should match the production goals and market demand of the enterprise.

- Capacity planning needs to consider factors such as production efficiency, equipment utilization rate, and production rhythm.

- Product Process Characteristics:

- The custom production line should fully consider the special process requirements of the product, such as temperature, humidity, cleanliness, etc.

- The design of the process flow should ensure product quality while meeting the requirements of production efficiency.

- Degree of Automation:

- The degree of automation is a key factor in the design of custom production lines, which can significantly improve production efficiency and reduce labor costs.

- The selection of automated equipment should be based on product characteristics, production scale, and budget.

- Flexibility and Scalability:

- Custom production lines should have a certain degree of flexibility to adapt to changes in product updates or market demands.

- Scalability refers to the ability of the production line to add equipment or adjust layouts in the future to meet larger production needs.

- System Integration:

- The various components of a custom production line, such as robotic arms, conveyor belts, control systems, etc., need to be highly integrated to achieve a smooth production process.

- System integration also includes the connection with enterprise resource planning (ERP), manufacturing execution system (MES), and other software.

- Maintenance and Support:

- The design of a custom production line should consider the maintenance and support of equipment to ensure the long-term stable operation of the production line.

- Choosing equipment and systems that are easy to maintain and upgrade can reduce long-term operating costs.

- Safety and Environmental Protection:

- Safety is an indispensable factor in the design of production lines and should ensure that all operations comply with safety standards.

- Environmental protection is also an important consideration in the design of modern production lines, and measures should be taken to reduce energy consumption and waste emissions.

- Cost-Benefit Analysis:

- A comprehensive cost-benefit analysis should be conducted when designing a custom production line to ensure a reasonable return on investment.

- Costs include equipment purchase, installation, operation, and maintenance.

- User Involvement:

- The involvement of users or operators is crucial for the success of a custom production line, and their understanding and feedback on the production process can guide the optimization of the production line.

The design of a custom production line is an interdisciplinary engineering project that requires knowledge and professional skills across various disciplines. It also requires continuous adjustment and optimization in response to market and technological developments.

RMU (Ring Main Unit):

- Structure: RMU is a compact type of switching equipment, commonly used in urban power distribution networks.

- Process: It adopts a modular design, which is easy to install and maintain, and typically includes components such as circuit breakers, load switches, and grounding switches.

VCB (Vacuum Circuit Breaker):

- Structure: VCB uses vacuum as the insulating and arc-extinguishing medium, characterized by its small size and light weight.

- Process: Its main advantages are long service life, low maintenance, and high reliability.

GIS (Gas Insulated Switchgear):

- Structure: GIS is a fully sealed metal enclosure filled with insulating gas (usually SF6).

- Process: GIS offers high reliability and safety, suitable for high-voltage and high-current applications.