The requirements for the assembly environment of RMU

The requirements for the assembly production environment of RMU ring main units (RMUs) typically include the following aspects:

- Environmental Conditions: The assembly production environment should be kept clean and dry, avoiding humidity and dust to ensure the insulation performance and normal operation of the mechanical parts of the RMU.

- Temperature and Humidity: The temperature and humidity of the production environment should be controlled within an appropriate range to prevent material deformation or a reduction in the performance of electrical components.

- Operational Safety: Necessary safety measures should be taken during the assembly process, including personal protective equipment for operators and ensuring electrical safety during operations.

- Equipment and Tools: Professional equipment and tools suitable for the assembly of RMUs should be used to ensure assembly accuracy and product quality.

- Quality Control: Strict quality control measures should be implemented during the production process, including inspection of raw materials, semi-finished products, and finished products, to ensure the performance and reliability of the RMU.

- Technical Specifications: Assembly production should follow relevant technical specifications and standards, such as GB3906, to ensure that the RMU meets industry standards and safety requirements.

- Environmental Protection Requirements: With the increasing awareness of environmental protection, the production of RMUs should minimize the impact on the environment, such as using solid insulating materials without SF6 gas and ensuring the recyclability of materials.

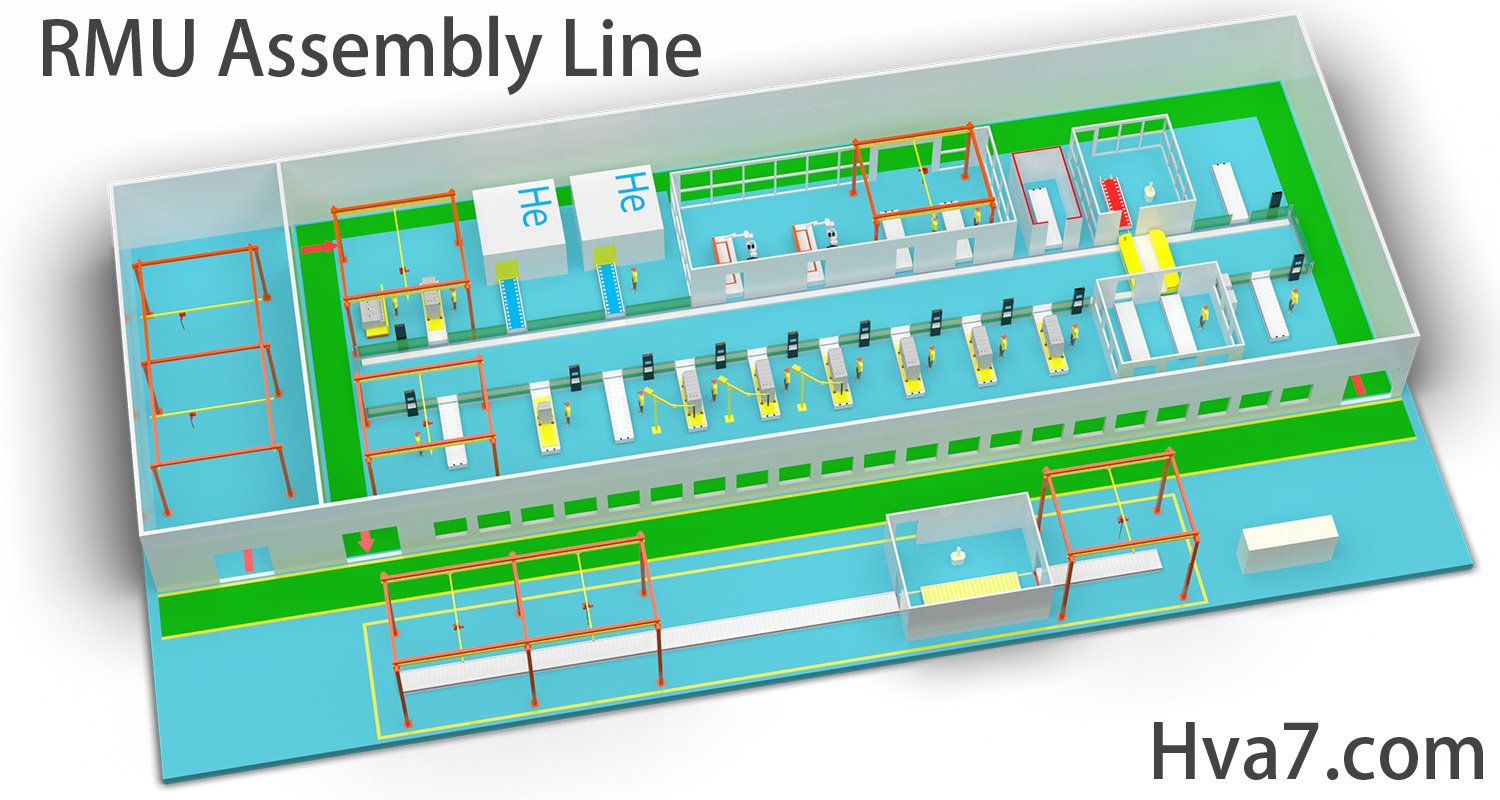

- Intelligence and Automation: The production of modern RMUs may involve the application of intelligent and automated technologies to improve production efficiency and reduce human error.

- Maintenance and Testing: After assembly, RMUs should undergo necessary maintenance and testing, including visual inspection, main circuit resistance measurement, mechanical operation and mechanical characteristic measurement tests, insulation resistance tests, etc., to ensure their performance meets the requirements before being put into use.

- Training and Skills: Operators should receive professional training to master the assembly techniques and knowledge of RMUs to ensure the professionalism of the assembly process.

These requirements ensure the quality and performance of RMUs during the production process, as well as the safety of operators and environmental protection.