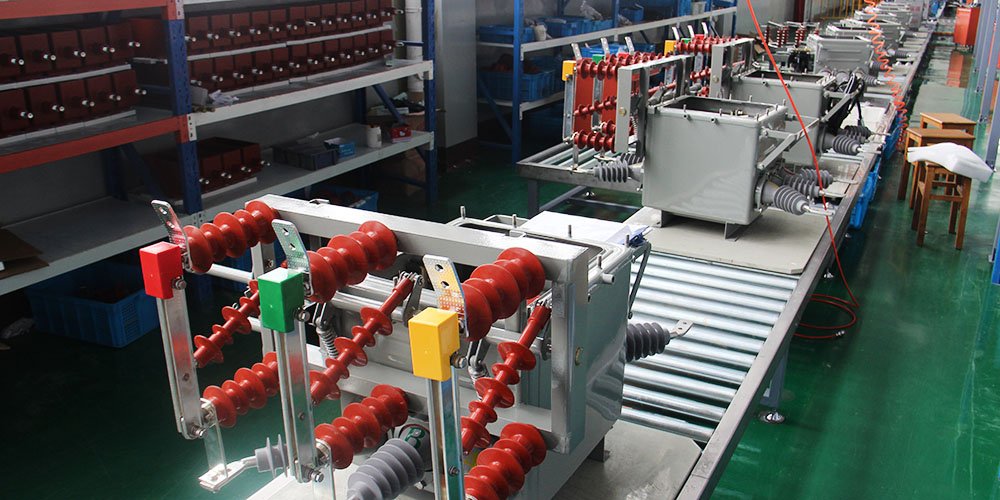

Post Circuit Breaker Assembly Production line

The assembly production line process for pole-mounted circuit breakers involves a series of specialized steps to ensure the manufacturing of high-quality and reliable equipment. Here is the process:

- Material Procurement and Inspection:

- All necessary materials, including conductive components, insulators, housing, and protective gear, are procured and inspected for quality and compliance with specifications.

- Component Fabrication:

- Individual components are fabricated through processes such as machining, stamping, and forming to meet the precise dimensions and tolerances required for assembly.

- Subassembly Preparation:

- Smaller subassemblies, such as the contact assembly and operating mechanisms, are prepared. This may involve the assembly of moving parts, springs, and other components that facilitate the opening and closing of the circuit breaker.

- Assembly of Major Components:

- The main components of the pole-mounted circuit breaker, such as the housing and insulators, are assembled. This step ensures that all parts are correctly aligned and securely fastened.

- Installation of Electrical Components:

- Electrical components, including the contacts and conductors, are installed and connected according to the design specifications. This step requires precision to ensure proper electrical connections and functioning.

- Integration of Protective Devices:

- Protective devices, such as arc chutes and fault indicators, are integrated into the circuit breaker assembly. These components are critical for the safety and reliability of the circuit breaker during operation.

- Functionality Testing:

- The assembled circuit breaker undergoes a series of functionality tests to ensure that the mechanical operations, such as opening and closing, are performed correctly.

- Electrical Testing:

- Comprehensive electrical tests are conducted to verify the circuit breaker’s performance under various conditions, including short-circuit current testing and load carrying capacity checks.

- Quality Control and Inspection:

- Each unit is inspected for quality control, checking for any defects or non-conformities. This step ensures that the product meets the required standards for safety and performance.

- Final Assembly and Packaging:

- After passing all tests, the circuit breaker is given final touches, such as applying protective coatings or labels, and then packaged for transportation.

- Documentation and Dispatch:

- Documentation is prepared, including test certificates and operation manuals, and the packaged circuit breakers are dispatched to the customers or storage facilities.