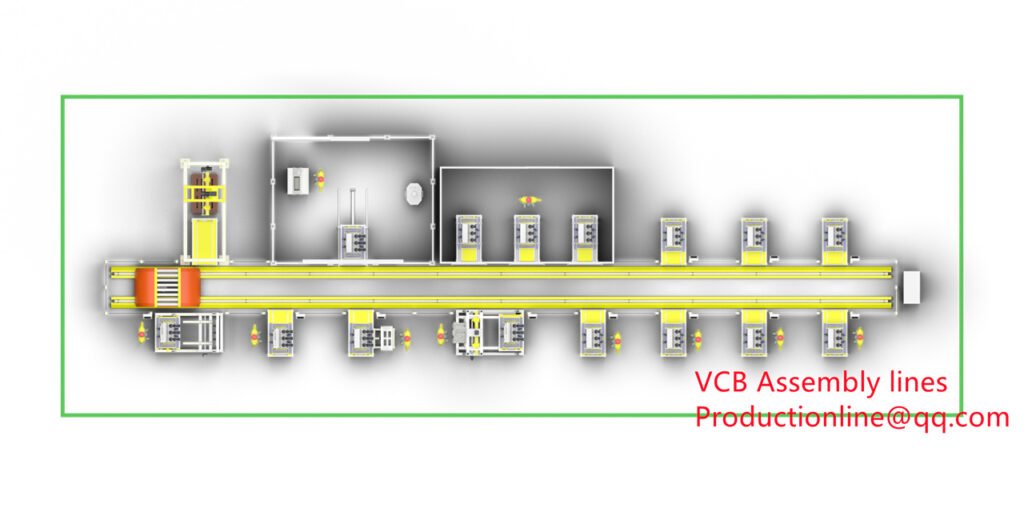

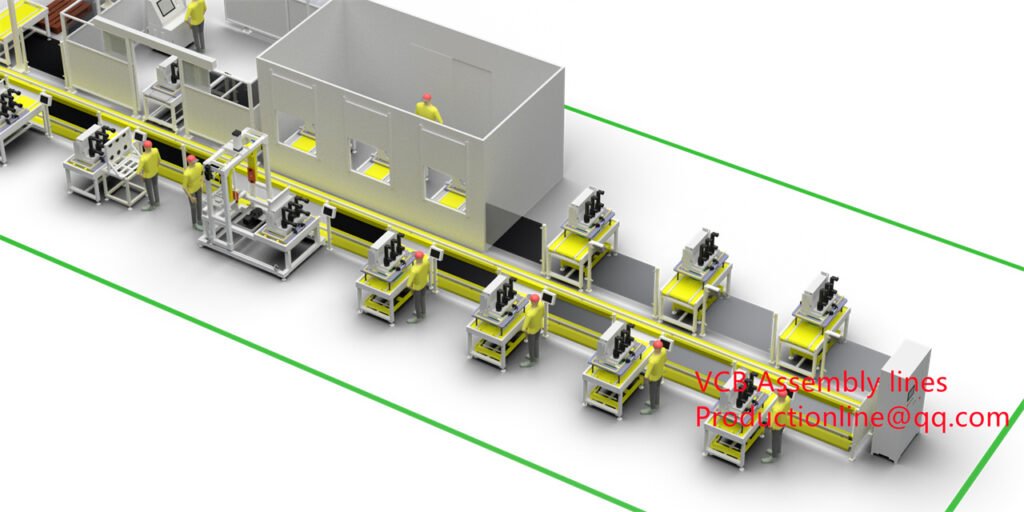

VCB Assembly lines Manufacturing production line

Indoor vacuum circuit breaker production lines are highly automated, featuring a structured assembly process that includes the integration of core components like vacuum interrupters and operating mechanisms. These lines are equipped with PLC-controlled systems for efficient operation, and they incorporate testing phases to ensure product quality. Advanced MES (Manufacturing Execution System) integration allows for real-time data collection, process monitoring, and seamless interaction with ERP and other systems, enhancing production efficiency and traceability.

Vacuum circuit breakers are a type of high-voltage switching equipment that utilizes vacuum as both the insulating and arc-extinguishing medium. The structure of indoor vacuum circuit breakers mainly includes the vacuum interrupter, operating mechanism, and supporting components. Here is information on the structure of indoor vacuum circuit breakers, assembly and testing process, automated production lines, and MES (Manufacturing Execution System):

Structure of Vacuum Circuit Breakers

- Vacuum Interrupter: The core component of the vacuum circuit breaker, responsible for extinguishing the arc when breaking the current. It typically consists of a hermetically sealed container made of ceramic, glass, or microcrystalline glass, with dynamic and static end plates, and a stainless steel bellows, ensuring hermeticity.

- Operating Mechanism: It can be a spring operating mechanism, electromagnetic operating mechanism, etc., responsible for the closing and tripping operations of the circuit breaker.

- Supporting Components: Including insulating supports and insulators, providing necessary mechanical support and insulation protection for the circuit breaker.

Assembly and Testing Process

- Main Shaft Assembly: Assemble the main shaft of the operating mechanism with other components.

- Mechanism Assembly: Assemble the rest of the operating mechanism to ensure its correct operation.

- Cabinet and Spring Assembly: Assemble the cabinet and springs to provide the necessary force for the operating mechanism.

- Phase Column Pre-assembly and Assembly: Pre-assemble and then officially assemble the phase columns into the circuit breaker.

- Chassis Assembly: Complete the assembly of the circuit breaker’s chassis.

- Characteristics Testing: Test various technical indicators of the circuit breaker, such as insulation level, contact bounce time, etc.

- Mechanical Run-in: Conduct mechanical run-in to ensure smooth operation of the operating mechanism.

Automated Production Line

Automated production lines, through the configuration of imported drive motors, PLC control systems, and sensors, achieve the automation of circuit breaker production. The production line includes automatic assembly, automatic testing, and automatic scheduling, reducing manual intervention and improving production efficiency.

MES System (Manufacturing Execution System)

The MES system is used to integrate factory control devices and processes to improve production efficiency and traceability. It can achieve production data collection, production instruction issuance, quality management, equipment management, report statistics, advanced automatic scheduling, and other functions. The MES system can also form a linkage with the ERP system, logistics system, inventory system, etc., to create a large closed-loop linkage system.