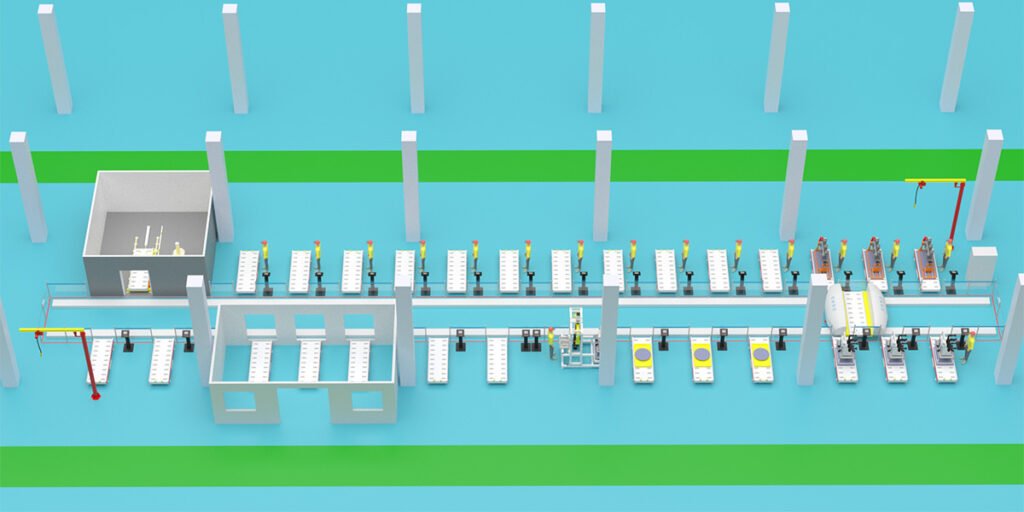

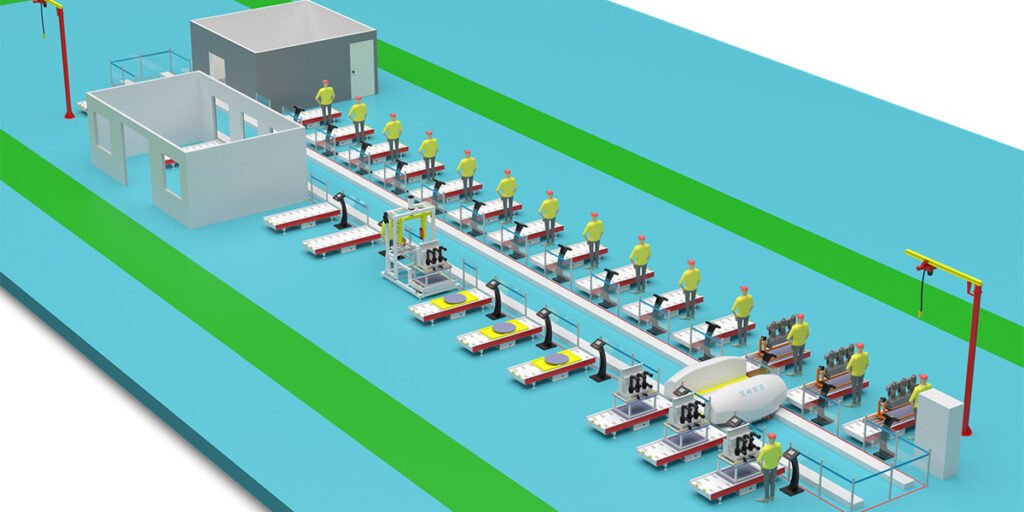

Mixed assembly line for various vacuum circuit breakers

The use of assembly lines in the production of vacuum circuit breakers offers numerous benefits, such as increased efficiency, standardized assembly processes, reduced human error, and improved quality control. It allows for continuous and synchronized production, which enhances productivity and reduces manufacturing costs. Additionally, assembly lines facilitate the integration of automation and precision tools, ensuring consistent and high-quality output of vacuum circuit breakers.

Vacuum circuit breakers can be categorized into low voltage, medium voltage, and high voltage types based on their rated voltage and application scenarios. Low voltage vacuum circuit breakers are used in distribution systems below 1kV, medium voltage types are applied in power systems ranging from 1kV to 35kV, and high voltage types are utilized in transmission lines above 35kV and large substations. Additionally, based on the installation environment, they can be divided into outdoor and indoor types to accommodate various operating conditions.

The assembly process of vacuum circuit breakers involves meticulous steps including main shaft assembly, mechanism assembly, spring installation, phase column pre-assembly, secondary circuit wiring, mechanical run-in, and final testing.