Intelligent Production System for Switchgear Cabinet Sheet Metal Processing with Robots

I. Equipment Composition

1. Storage Unit

- Function: Mainly used for the storage of raw materials, semi-finished products, and finished products. It connects with the cutting and shearing unit, bending unit, and palletizing unit to achieve the input and output of materials.

- Composition:

- Racking: Used for storing raw materials and finished products of different specifications. The racking is designed reasonably to meet the storage needs of materials of various sizes and weights.

- Stacker Crane: Responsible for transporting materials between the racks to achieve automated storage and retrieval. The stacker crane is equipped with an advanced navigation system that can accurately locate the position of the racks to ensure the precise transportation of materials.

- Conveyor System: Connects the storage unit with various processing units to transport materials from the storage unit to the processing units, or from the processing units back to the storage unit. The conveyor system uses belt or roller conveyors, which are characterized by stable operation and low noise.

- Features:

- Automated Storage and Retrieval: Through an automated control system, it realizes the automated storage and retrieval of materials, improving storage efficiency.

- Inventory Management: Equipped with an advanced inventory management system that monitors the inventory of materials in real-time, facilitating the formulation of production plans and the replenishment of materials.

- Flexible Design: The racking and conveyor system can be adjusted flexibly according to production needs to adapt to the storage of materials of different specifications and quantities.

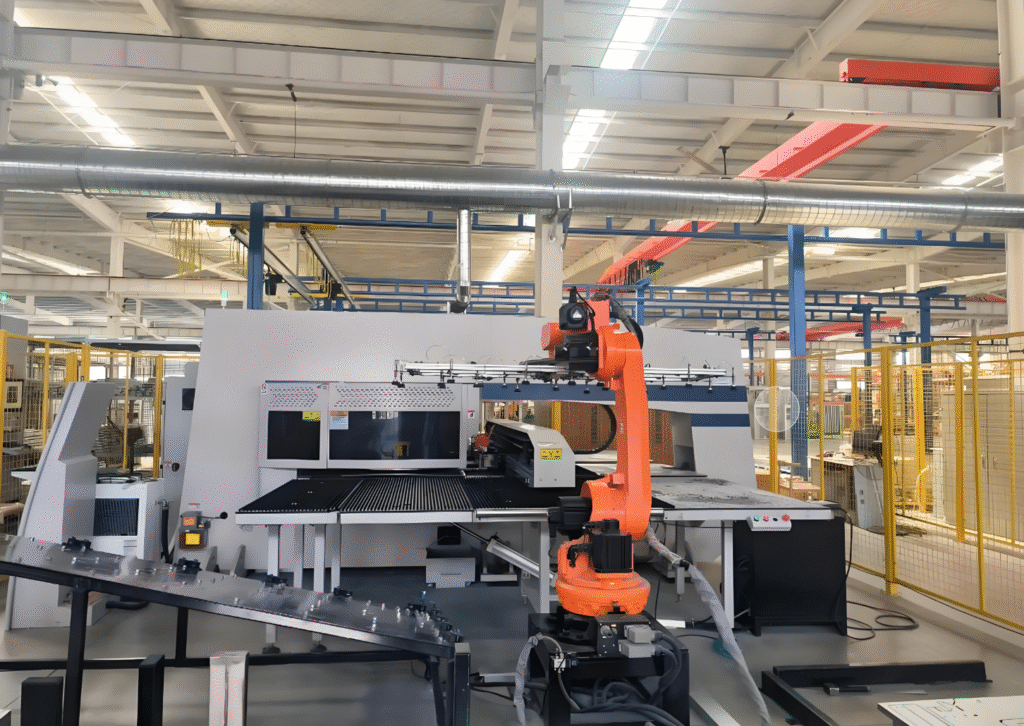

2. Cutting and Shearing Unit

- Function: Performs cutting and shearing operations on raw materials. The processed components can be directly sent to the bending unit or returned to the storage unit as needed.

- Composition:

- Press Brake: Used for punching and blanking operations on raw materials. The press brake is equipped with a high-precision numerical control system that can achieve complex punching patterns and high-precision processing requirements.

- Shearing Machine: Used for shearing operations on raw materials. The shearing machine is equipped with an automatic feeding device that can achieve continuous shearing, improving production efficiency.

- Robot Loading and Unloading System: The robot is responsible for transporting raw materials from the storage unit to the cutting and shearing unit and sending the processed components to the bending unit or back to the storage unit. The robot is equipped with an advanced vision system that can accurately identify and grasp materials.

- Features:

- High-Precision Processing: The press brake and shearing machine are equipped with high-precision numerical control systems to ensure the dimensional and positional accuracy of the processed components.

- Automated Loading and Unloading: The robot loading and unloading system achieves automated operation, reducing manual intervention and improving production efficiency and processing quality.

- Flexible Processing: The cutting and shearing unit can quickly adjust processing parameters to adapt to the processing needs of raw materials of different specifications and shapes.

3. Bending Unit

- Function: Composed of bending robots and bending machines, it can achieve automatic centering, bending, flipping, and palletizing processes for side panels and front panels of switchgear cabinets, realizing unmanned operations.

- Composition:

- Bending Robot: Responsible for transporting the processed components from the cutting and shearing unit to the bending machine and assisting in the bending process. The bending robot is designed with advanced articulated joints, offering high flexibility and precision.

- Bending Machine: Used for bending operations on components. The bending machine is equipped with a high-precision numerical control system and an automatic centering device, capable of achieving complex bending processes and high-precision processing requirements.

- Flipping Device: Used to flip the components to the specified position to facilitate multi-angle bending operations by the bending machine.

- Features:

- High-Precision Bending: The bending machine, with its high-precision numerical control system and automatic centering device, ensures the dimensional and angular accuracy of the bent components.

- Automated Operation: The combination of bending robots and bending machines achieves automated bending, reducing manual intervention and improving production efficiency and processing quality.

- Flexible Processing: The bending unit can quickly adjust bending parameters to adapt to the processing needs of components of different specifications and shapes.

4. Palletizing Unit

- Function: Used to stack the finished products for convenient transportation and storage.

- Composition:

- Palletizing Robot: Responsible for transporting the finished products from the bending unit to the palletizing area and stacking them neatly according to the specified palletizing method. The palletizing robot is designed with advanced articulated joints, offering high flexibility and precision.

- Palletizing Platform: Used for storing the stacked finished products. The palletizing platform is designed reasonably to meet the stacking needs of finished products of different specifications and quantities.

- Conveyor System: Connects the palletizing unit with the storage unit to transport the stacked finished products to the storage unit for storage.

- Features:

- Automated Palletizing: The palletizing robot achieves automated palletizing, improving palletizing efficiency and quality.

- Flexible Palletizing: The palletizing robot can adjust the palletizing method flexibly according to the specifications and quantities of the finished products, adapting to different palletizing needs.

- Safety and Reliability: The palletizing platform and conveyor system are designed reasonably to ensure the safety and reliability of the palletizing and transportation processes.

5. Data Management and Control Unit

- Function: The core of data management and control for the entire system, responsible for the transmission, collection, processing, and output of control commands to achieve intelligent management and control of the entire production process.

- Composition:

- Central Control System: In charge of controlling and managing the entire production system, including monitoring the operating status of equipment, formulating and scheduling production plans, collecting and analyzing data, etc.

- Network Communication System: Enables data communication between various equipment to ensure the rapid transmission and sharing of information.

- Data Acquisition System: Responsible for collecting operating data from various equipment and quality data from the production process, providing data support for production management and quality control.

- Features:

- Intelligent Management and Control: Through the central control system, it achieves intelligent management and control of the entire production process, improving production efficiency and quality.

- Real-Time Monitoring and Scheduling: Real-time monitoring of the operating status of equipment and production progress, dynamic scheduling according to production plans to ensure the smooth progress of the production process.

- Data Analysis and Optimization: By analyzing production data, it optimizes production processes and equipment parameters to improve production efficiency and quality.

6. Robots and Supporting Equipment

- Function: Composed of multiple articulated robots and supporting feeding platforms, the vision-guided robots equipped with automatic tightening guns complete operations such as riveting and welding.

- Composition:

- Articulated Robots: Used to perform various processing operations, such as riveting and welding. The articulated robots are designed with advanced articulated joints, offering high flexibility and precision.

- Feeding Platform: Used to supply materials needed for processing by robots. The feeding platform is designed reasonably to meet the supply needs of materials of different specifications and quantities.

- Vision System: Used to guide robots to perform precise operations, such as grasping materials and locating processing positions. The vision system uses advanced image recognition technology to achieve high-precision vision guidance.

- Automatic Tightening Gun: Used to complete operations such as riveting and welding. The automatic tightening gun is equipped with a high-precision torque control system to ensure the quality of riveting and welding.

- Features:

- High-Precision Operation: The combination of articulated robots and vision systems achieves high-precision operations, improving processing quality.

- Automated Processing: Robots and supporting equipment achieve automated processing, reducing manual intervention and improving production efficiency and processing quality.

- Flexible Processing: Robots and supporting equipment can quickly adjust processing parameters to adapt to the processing needs of materials of different specifications and shapes.

II. Process Features

1. High Degree of Automation

- Description: It adopts a streamlined production process of automatic loading, cutting, shearing, bending, and palletizing, replacing the traditional single-machine operation mode in separate areas. This reduces manual intervention and improves production efficiency and product quality.

- Advantage: Reduces manual operation, lowers labor intensity, and enhances production efficiency and processing quality.

2. Flexible Production

- Description: It can quickly adapt to the processing needs of switchgear cabinet sheet metal parts of different specifications and models, with fast production changes and short preparation times. It has high adaptability and versatility, enabling the production of multiple varieties and small batches.

- Advantage: Quickly responds to market demands, improves production flexibility and market competitiveness.

3. High Processing Precision

- Description: By using high-precision robots and numerical control equipment, as well as advanced vision systems and other technologies, it ensures the dimensional and positional accuracy of the processed components, improving the stability of product quality.

- Advantage: Improves product quality, reduces the rate of defective products, and enhances the corporate brand image.

4. High Production Efficiency

- Description: Robots can process continuously without interruption, significantly improving production efficiency. Compared with traditional processing methods, the processing efficiency of a complete set of sheet metal parts can be increased by more than 40%.

- Advantage: Improves production efficiency, shortens production cycles, and meets market demands.

5. Reliable Quality

- Description: Robots operate in a standardized and stable manner, avoiding quality fluctuations caused by human factors, ensuring better finished product quality.

- Advantage: Improves the stability of product quality, reduces quality complaints, and lowers after-sales costs.

6. Energy-Saving and Environmental Protection

- Description: The entire production process is more efficient and energy-saving, reducing energy consumption and waste generation, in line with the requirements of sustainable development.

- Advantage: Reduces production costs, minimizes environmental pollution, and complies with environmental protection policies.