Options for Switchgear Cabinet Sheet Metal Painting Surface Coatings Production Line

Characteristics of Surface Coatings on Power Switchgear Enclosures

- Good Adhesion: The coating firmly adheres to the surface of the enclosure, ensuring long-term protection even when subjected to mechanical impacts or vibrations.

- Excellent Wear Resistance: In the usage of switchgear, the coating withstands frequent friction and wear, such as during switch operations and equipment handling, extending its service life and maintaining its protective and decorative functions.

- Strong Corrosion Resistance: Power switchgear is often exposed to various complex environments, where it may come into contact with corrosive media like moisture and chemicals. The surface coating provides strong corrosion resistance, preventing rust and corrosion of the enclosure, ensuring its normal operation and extending its lifespan.

- Aesthetic Appearance: The coating has a uniform color and smooth surface, enhancing the overall aesthetic quality of the switchgear, making it more visually appealing and in line with modern industrial equipment standards.

- Good Insulation Properties: For power switchgear, insulation is crucial. The coating offers additional insulation protection, reducing the risk of electrical leakage due to surface coating damage and enhancing the safety of the switchgear.

Surface Treatment Process for Power Switchgear Enclosures

- Pre-treatment:

- Degreasing: Using degreasing agents to remove oils and grease from the enclosure surface, providing a clean surface for subsequent treatment processes. Common degreasing methods include chemical degreasing and electrochemical degreasing.

- Pickling: Removing scale, rust, and other impurities from the enclosure surface through pickling, revealing the fresh metal substrate and creating a suitable surface for coating adhesion. After pickling, neutralization is required to remove residual acid.

- Phosphating: Forming a uniform phosphate layer on the enclosure surface, which enhances the adhesion between the coating and the metal substrate and improves the corrosion resistance of the coating. There are various phosphating processes, such as zinc phosphate and iron phosphate.

- Spraying:

- Electrostatic Spraying: A widely used spraying process in modern industry. It utilizes an electrostatic field to attract charged paint particles to the grounded workpiece surface, forming a uniform coating. Electrostatic spraying offers advantages such as uniform coating, strong adhesion, high paint utilization, and minimal environmental pollution, making it suitable for large-scale industrial production.

- Arc Spraying: A thermal spraying technique that heats the coating material to a molten state using an electric arc and sprays it onto the workpiece surface using compressed air to form a coating. Arc spraying can produce coatings with high bond strength, good wear resistance, and corrosion resistance, suitable for applications with high coating performance requirements.

- Curing: The sprayed coating needs to undergo curing treatment to allow the resin and other components in the coating to undergo chemical reactions, forming a hard protective film. Curing methods include natural drying, hot air drying, and infrared curing. Among these, hot air drying and infrared curing can accelerate the curing process and improve production efficiency.

Spray Painting Production Line Equipment

- Pre-treatment Equipment:

- Degreasing Tank: Used for holding degreasing agents to perform degreasing on the enclosure. It typically includes heating and stirring devices to ensure effective degreasing.

- Pickling Tank: Used for the pickling process. The tank is made of acid-resistant materials, such as plastic or stainless steel. It also features heating and stirring devices to ensure uniform distribution and complete reaction of the pickling solution.

- Phosphating Tank: Used for phosphating treatment, with a structure similar to the pickling tank. The temperature and solution concentration in the tank need to be controlled according to the specific phosphating process requirements.

- Spraying Equipment:

- Electrostatic Spraying Equipment: Comprises an electrostatic spray gun, high-voltage electrostatic generator, and powder recovery system. The spray gun is a key component for coating quality; the high-voltage electrostatic generator provides the electrostatic field for the spray gun; the powder recovery system recovers excess powder that did not adhere to the workpiece surface, improving paint utilization.

- Arc Spraying Equipment: Mainly consists of a spraying power supply, wire feeding device, and spray gun. The spraying power supply provides the current and voltage required for the electric arc, the wire feeding device evenly feeds the coating material into the spray gun, and the spray gun sprays the molten material onto the workpiece surface.

- Curing Equipment:

- Baking Oven: The primary device for curing the coating. The uniformity of the internal temperature of the oven is crucial for ensuring coating quality. The heating methods of the baking oven include radiation, hot air circulation, and a combination of radiation and hot air circulation. Depending on the production requirements, the oven can be single-chamber or through-type, and the equipment can be straight-through or bridge-type. Hot air circulation baking ovens offer good insulation, uniform temperature distribution, and low heat loss. Tests have shown that the temperature difference within the oven is less than ±3°C.

- Infrared Curing Equipment: Utilizes the heat from infrared radiation to quickly cure the coating. It has advantages such as fast curing speed, low energy consumption, and compact equipment size, but it has certain requirements for the thickness and material of the coating.

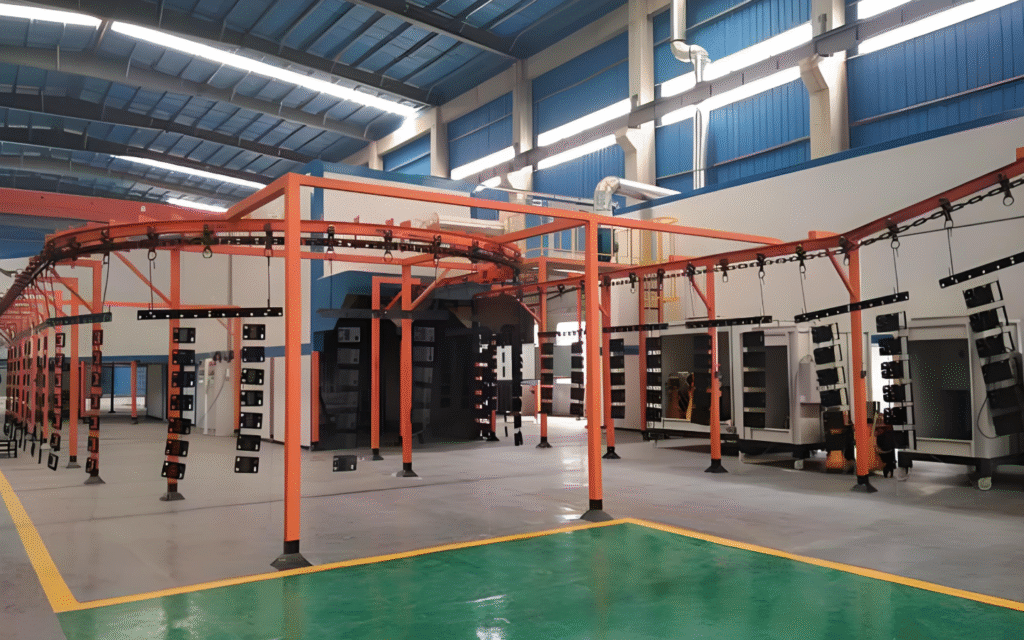

- Conveying Equipment: Used to transport the enclosure workpieces along the production line. Common types include overhead conveyors, ground roller conveyors, and elevators. The conveying equipment needs to be designed according to the layout and process requirements of the production line to ensure smooth transfer of workpieces between different processes.

- Auxiliary Equipment: Also includes devices for detection and control, such as coating thickness gauges, temperature and humidity sensors, and automated control systems. Coating thickness gauges are used to monitor the thickness of the coating to ensure it meets the required specifications. Temperature and humidity sensors help maintain the optimal environmental conditions for the coating process, while automated control systems manage the entire production line, ensuring efficient and consistent operations.

Characteristics and Benefits of Automated Assembly Line Production for Surface Coating of Power Distribution Cabinet Enclosures in the Power Industry

Automated assembly line production for surface coating of power distribution cabinet enclosures in the power industry has the following significant characteristics and numerous benefits:

Characteristics

- High Degree of Automation: The entire coating production process, from loading the workpieces to pre-treatment, spraying, curing, and unloading, is fully automated, requiring minimal manual intervention. This greatly improves production efficiency and the stability of product quality.

- Continuous Production: The assembly line production method allows workpieces to flow continuously between various processes, reducing downtime and waiting times in the production process. It enables large-scale, continuous production, meeting the power industry’s demand for mass production of distribution cabinets.

- Integrated Processes: Multiple surface coating treatment processes, such as degreasing, pickling, phosphating, electrostatic spraying, and curing, are integrated into a single production line. This achieves a compact and integrated process flow, saving production space and improving equipment utilization.

- Precise Control: With advanced automated control systems, various parameters in the production process, such as temperature, humidity, spraying pressure, paint flow rate, and conveying speed, can be precisely controlled. This ensures the consistency and uniformity of coating quality, effectively avoiding quality fluctuations caused by human factors.

Benefits

- Increased Production Efficiency: The automated assembly line can quickly and continuously complete the surface coating of distribution cabinet enclosures, significantly reducing production cycles and increasing output per unit of time. This helps power companies quickly respond to market demands and enhance their market competitiveness.

- Improved Product Quality: Automated equipment ensures that coating thickness, uniformity, adhesion, and other quality indicators reach high levels. This provides better protection, decorative effects, and insulation properties for the surface coating of distribution cabinet enclosures. As a result, the service life of distribution cabinets is extended, and their operational reliability and safety are improved.

- Reduced Labor Costs: The need for manual labor is reduced, lowering labor costs. At the same time, reducing manual operations also decreases the risk of quality issues and safety accidents caused by human errors, further reducing the operational costs of enterprises.

- Optimized Production Environment: Automated assembly line production systems are typically equipped with complete exhaust gas treatment and dust recovery systems. These can effectively reduce the emission of harmful gases and dust during the spraying process, improving the production environment and meeting environmental protection requirements. This is conducive to the sustainable development of enterprises.

- Enhanced Production Flexibility: Although primarily used for mass production, automated assembly line production systems can also meet the production requirements of different specifications and coating types of distribution cabinet enclosures to a certain extent by adjusting process parameters and equipment configurations. This provides a certain degree of production flexibility to adapt to the diverse product needs of the power industry.

- Traceability of Data: Automated control systems can record various data from the production process, such as production time, process parameters, and equipment operating status. This enables traceability of product quality. In the event of quality issues, the problematic link can be quickly located, facilitating cause analysis and quality improvement.