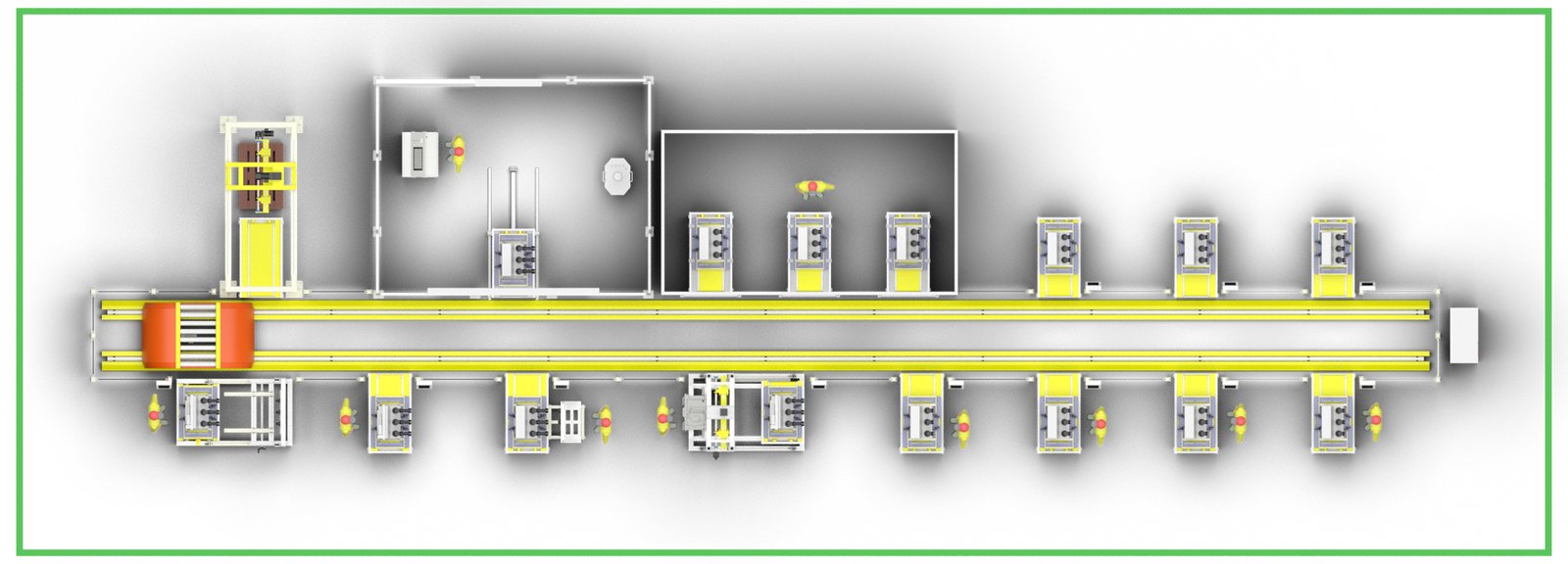

Vacuum Circuit Breakers Assembly Line

The VCB assembly line is used for the assembly and production of vacuum circuit breaker assemblies, including the assembly of shell components, vacuum poles, electrical components, contact arms, chassis vehicles, etc. The assembly line is also equipped with running in tests, mechanical characteristic adjustments, pressure tests, isolation rooms, etc.

Modular design of vacuum circuit breaker (VCB) assembly line

VCB automatic lifting equipment

– Automatic lifting function

– Automatic clamping vacuum circuit breaker housing

– Clamping torque control

– Lift position control

– Optional independent PLC control

– Automatic walking and position control

– Reduce manual handling

– Improve automation level

– Modular assembly

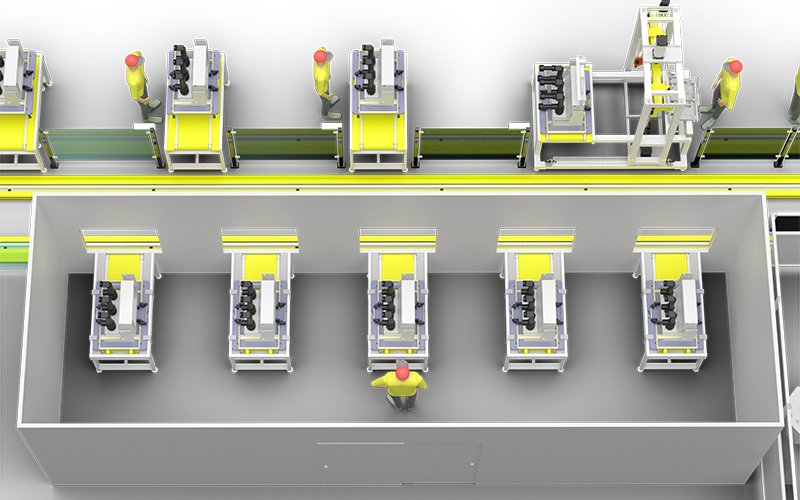

VCB Operation workstation

– Automatic conveying

– Variable frequency drive speed regulation, pneumatic stop smooth operation

– Adapt to various specifications of vacuum circuit breakers

– Lift function, optional servo or pneumatic

– Manual rotation function

– Aluminum alloy profiles and steel square tube frames

– Station touch screen

– Positioning device

– Modular design for assembly and production of vacuum circuit breakers

VCB testing soundproof room

Test bench for automatic conveying and connecting

Equipped with noise reduction function

Equipped with vibration buffering function

Automatic entrance and exit control of testing room

Isolation doors are installed for the entrance and exit of the testing room

Isolation room equipped with automatic doors

Modular assembly

Dealing with different testing needs and calmly responding

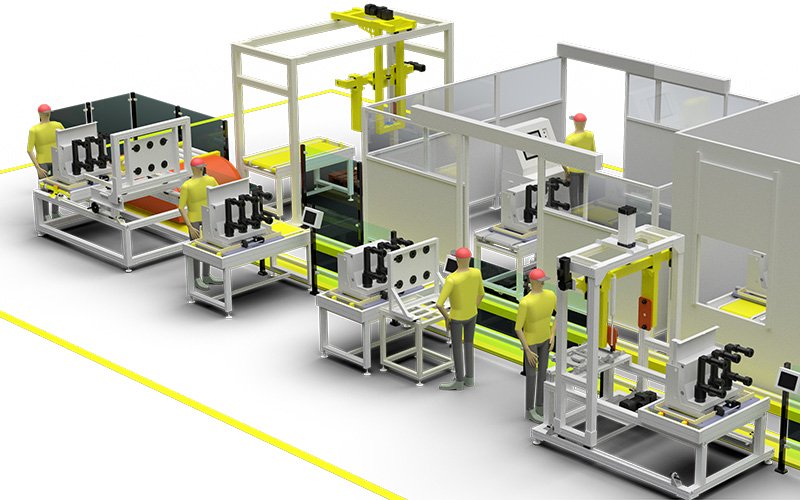

Vacuum circuit breaker assembly equipment

-Automated auxiliary equipment for the assembly of vacuum circuit breaker chassis vehicles

-Automation auxiliary equipment for poles

-Mechanical characteristic adjustment workbench for vacuum circuit breakers

-Automated docking of conveyor lines

-Automated offline mechanism

-High voltage testing

-Automation equipment optimized for assembly and production of vacuum circuit breakers

-Modular supply

The introduction of automation equipment can significantly improve the assembly quality of vacuum circuit breakers, improve production efficiency, and reduce labor intensity.

Note: There are differences in the structure of vacuum circuit breakers from different brands, and the layout of the production line will change with the production process. For more solutions, please contact our engineers.