Vacuum circuit breaker assembly production environment

The assembly and production environment for vacuum circuit breakers (VCBs) needs to meet specific conditions to ensure the quality and performance of the equipment. Here are some key environmental requirements for VCB assembly and production by Hva7:

- Temperature and Humidity Control: The production environment should maintain stable temperature and humidity levels to prevent damage to VCB components from extreme temperatures and high humidity.

- Cleanliness: Since vacuum circuit breakers involve high voltage and precision electrical parts, the production area should be kept clean to reduce the impact of dust and other contaminants.

- Dust and Moisture Protection: Dustproof and moisture-proof measures should be taken during the production process to protect the insulation performance and mechanical parts of the vacuum circuit breaker.

- Anti-static Measures: The assembly line should be equipped with anti-static facilities to prevent electrostatic damage to sensitive electronic components.

- Ventilation System: A good ventilation system helps control the temperature and air quality in the production area and ensures the health and safety of the operators.

- Safety Protection: The production area should be equipped with necessary safety protection devices and warning signs to prevent accidental injuries.

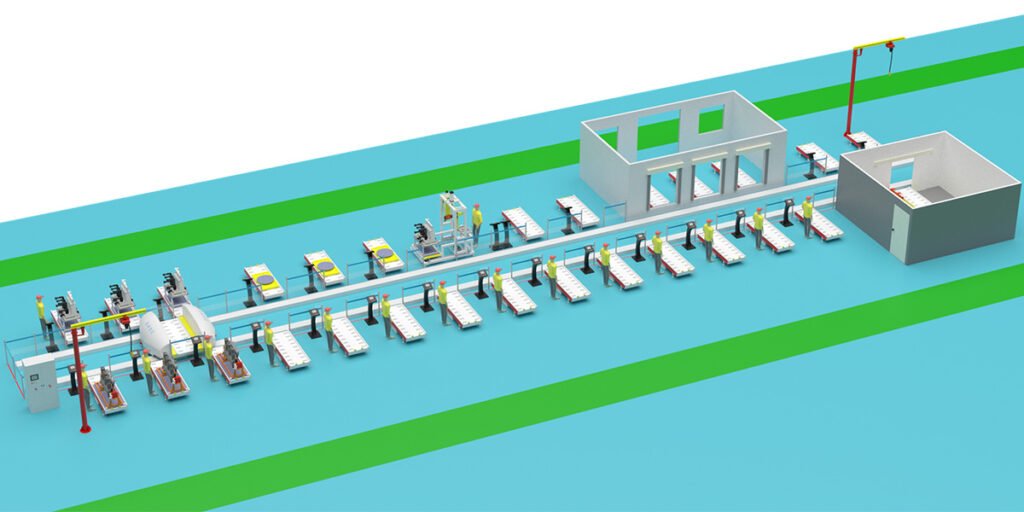

- Specialized Equipment: The production process may require the use of specialized equipment and tools, such as automatic assembly machines, testing equipment, and inspection machines, to improve production efficiency and product quality.

- Quality Control: There should be strict quality control processes, including inspection and testing of raw materials, components, and final products, to ensure the products meet technical standards.

- Noise Control: The noise level of the production line should be controlled within a reasonable range to avoid affecting the health and efficiency of the workers.

- Illumination: Adequate lighting is essential for precise assembly work, especially when making delicate electrical connections and installing components.

- Operating Space: Sufficient operating space should be provided so that workers can perform assembly and testing work comfortably.

- Environmental Protection: The production process should avoid the use of substances harmful to the environment, in compliance with environmental protection requirements.

By adhering to these environmental and operational standards, the assembly and production process of vacuum circuit breakers can be both safe and efficient, while ensuring product quality and performance.