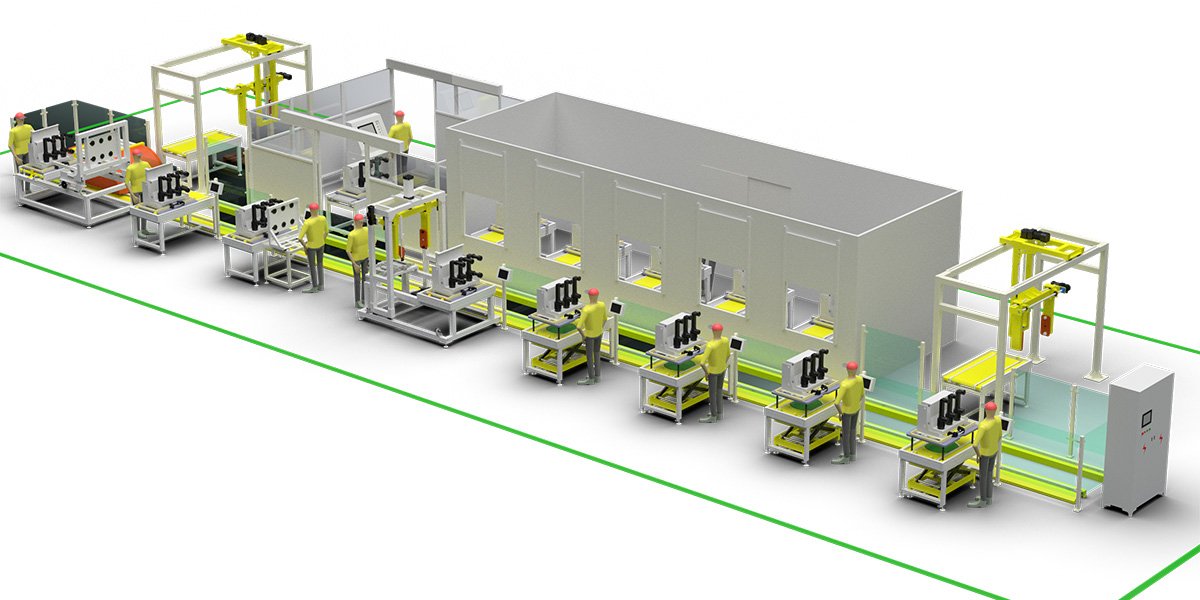

RGV Vacuum Circuit Breaker Assembly Production Line

In the assembly line for vacuum circuit breakers, RGV can play a significant role in improving production efficiency and assembly accuracy. RGV (Rail Guided Vehicle) is an automated material handling system that operates on fixed rails to achieve the automatic transportation of materials.

1. Automated Material Handling

RGV can automatically transport various components and semi-finished products of vacuum circuit breakers, thereby reducing the need for manual handling, lowering labor intensity, and increasing overall production efficiency.

2. Precise Positioning

RGV systems are typically equipped with precise positioning systems that can ensure the accurate placement of components on the assembly line, which is crucial for the assembly quality of vacuum circuit breakers.

3. Flexibility and Scalability

The RGV system can be adjusted according to production needs, with the ability to add or reduce rails and vehicles to adapt to different production processes and changes in output.

4. Reduced Production Interruptions

Through the use of RGV systems, production interruptions caused by manual handling can be minimized, achieving continuous production and improving production stability.

5. Lower Error Rates

Automated RGV systems can reduce human operation errors, enhancing the accuracy and reliability of the assembly line.

6. Easy Maintenance and Monitoring

RGV systems usually come with monitoring software that can monitor the status and location of the transport vehicles in real time, facilitating maintenance and troubleshooting.

7. Safety

The design of RGV systems typically takes safety into account, effectively preventing collisions between personnel and transport vehicles, ensuring the safety of workers.

8. Integration with Production Systems

RGV systems can be seamlessly integrated with other production equipment and information systems, enabling real-time transmission and analysis of production data, and optimizing production management.