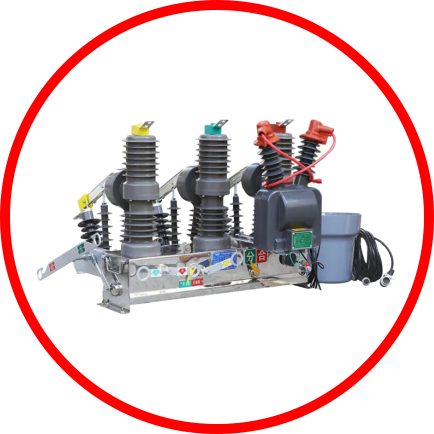

Pole-mounted Vacuum Circuit Breaker (PVB) Assembly line

Automated production system specifically designed for producing pole-mounted vacuum circuit breakers (PVB).

The production line of pole-mounted vacuum circuit breakers (PVB) usually includes the loading area, mechanism assembly area, waiting area, insulation cylinder assembly area, running in area, repair area, mechanical characteristic testing area, contact arm assembly area, and offline area. These areas are interconnected through automation equipment and control systems, ensuring the continuity and efficiency of the production process.

The tooling board serves as a carrier: During the production process, the tooling board carries various components of the PVB and moves on the production line. This design makes the production process more flexible and allows for adjustments to the production process as needed.

Suitable for the assembly and production of various types of pole-mounted vacuum circuit breakers

Automated assembly conveyor line to meet the requirements of mass production.