Power Distribution Cabinet Production line

Manufacturers of Power Distribution Cabinets offer a variety of products to cater to the needs of different industries and applications. The types of products typically include but are not limited to:

1.High-voltage Switchgear: For control and protection in high-voltage power systems, often including circuit breakers, isolating switches, grounding switches, and other components.

2.Low-voltage Distribution Boards: For distribution in low-voltage power systems, which may contain circuit breakers, contactors, relays, etc., suitable for commercial and industrial environments.

3.Ring Main Units (RMUs): Special switching equipment used in ring distribution networks to provide higher reliability and flexibility of power supply.

4.Box Substations: Integrated substations that typically include transformers and related control equipment, suitable for outdoor or space-limited locations.

5.Intelligent Distribution Cabinets: Equipped with intelligent control and monitoring systems for remote monitoring and automated control capabilities.

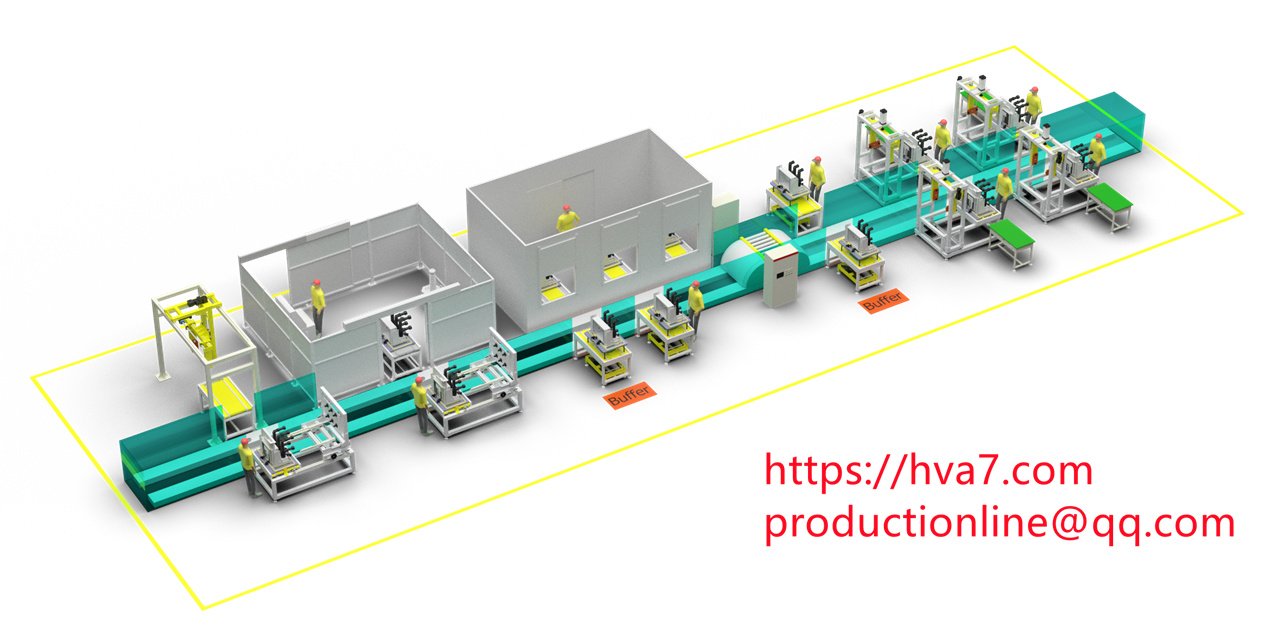

Regarding production lines, manufacturers typically employ automated and informatized processes to enhance efficiency and product quality. Features of these production lines may include:

1.Automated Assembly Lines: Utilizing automated machinery and robots for assembling various components of the distribution cabinet, such as circuit breakers and contactors.

2.Intelligent Assembly Mode: Incorporating intelligent sensors and control systems to perform operations like automatic wire stripping, cutting, and crimping.

3.MES Systems: Manufacturing Execution Systems for real-time monitoring and management of the production process to ensure efficiency and quality.

4.Modular Design Assembly line: The production line is modular, allowing for quick reconfiguration to meet different product requirements.

5.Quality Control: Equipped with various testing and inspection equipment to ensure each distribution cabinet meets quality standards before shipment.

6.Customized Production: Some lines offer customization to meet specific customer requirements and application needs.

These manufacturers are continuously seeking technological innovation and improved production efficiency to meet market demands and are actively involved in promoting industry upgrades and transformations in the context of intelligent manufacturing and Industry 4.0.