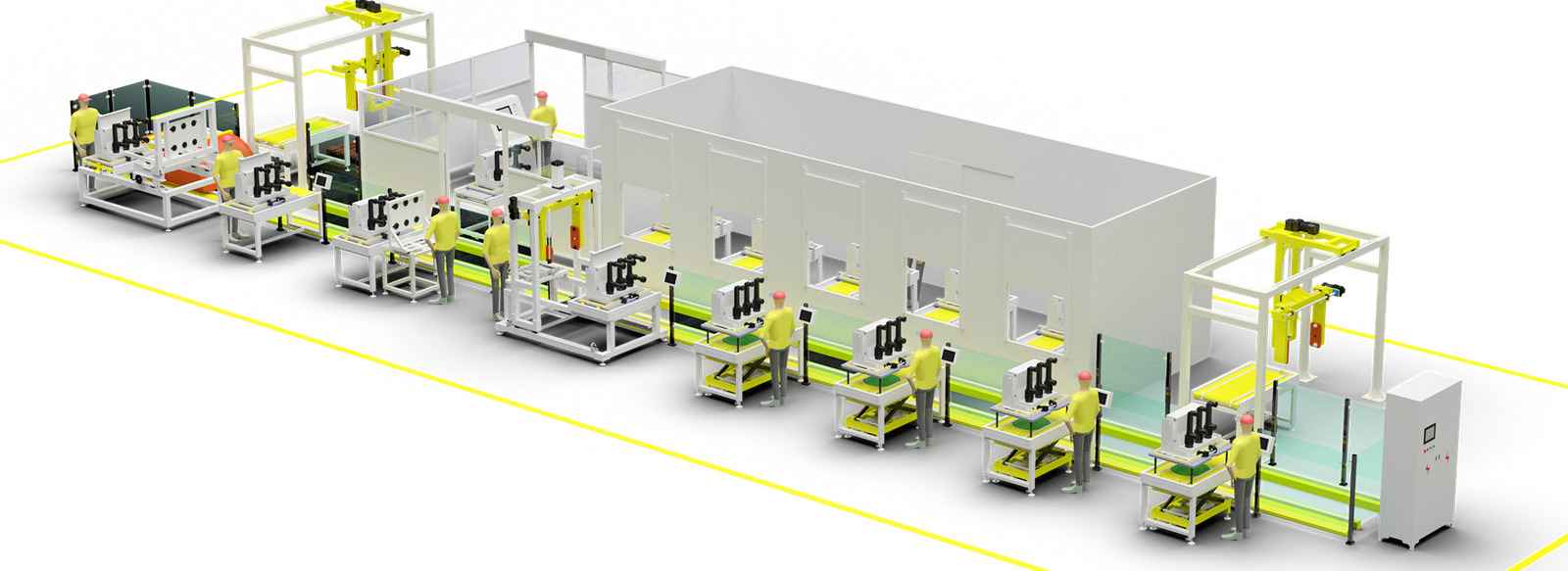

Indoor VCB Assembly Line

Indoor vacuum circuit breakers VCB assembly line

The indoor vacuum circuit breaker assembly line can meet diverse production needs.

1.Hard core technology: Emphasis on excellence in the assembly process of vacuum circuit breakers, from production equipment to improving product assembly quality.

2.Detail polishing: The assembly line can be equipped with a dust-free room to improve the performance of product assembly.

3.Green production: The assembly line adopts the concept of green design to save energy consumption.

4.Technology support: The integration of various automation control technologies in production has improved the reliability of indoor vacuum circuit breaker assembly.

5.Craftsmanship assembly: Modular device design, using bus communication technology, ensures first-class quality and a comprehensive worry free user experience.

6.Advanced Manufacturing Management: MES interface is optional, and the manufacturing execution management system runs through the entire production process, ensuring process visualization and production traceability, making product quality more controllable.

7.Human machine collaborative assembly: adopting ergonomic design, implementing the lean production concept, automatically identifying operations and paying attention to details, improving efficiency, and ensuring the quality of assembly.

8.Automatic testing: including running in test, characteristic detection, over range adjustment, insulation test, etc., to ensure that each vacuum circuit breaker undergoes comprehensive testing and ensures high quality.

The vacuum circuit breaker assembly production line, which meets the equipment requirements of the process, reflects its high attention to product quality, environmental protection, and technological innovation, ensuring the high performance and reliability of indoor vacuum circuit breakers.