Using a production line for the assembly and testing of VS1 vacuum circuit breakers offers several key advantages: It significantly enhances production efficiency and consistency, reduces human error, and ensures standardized quality control across all units. Automated processes, including robotic assembly and precision testing, guarantee high accuracy and repeatability in manufacturing. The integration of MES systems allows for real-time monitoring and data-driven decision-making, which streamlines operations and improves responsiveness to market demands. Furthermore, a clean room assembly environment maintains product integrity, while modular and flexible production lines cater to varying product specifications and volumes, accommodating diverse customer needs.

The VS1 vacuum circuit breaker is a type of high-voltage switching equipment known for its notable features and advantages. Here is information regarding the structure of the VS1 vacuum circuit breaker, assembly and testing process, automated production line, and MES (Manufacturing Execution System):

1.Structure of the VS1 Vacuum Circuit Breaker:

The VS1 vacuum circuit breaker typically comes in various voltage levels, with a compact size and light weight, suitable for frequent operations.

The equipment features a solid insulation structure, such as integrated solid-insulated poles, achieving maintenance-free operation.

The circuit breaker includes key components like insulating poles, primary contacts, vacuum interrupters, and insulating rods.

It is available in both fixed and trolley-mounted configurations, suitable for different types of switchgear.

2.Assembly and Testing Process:

The process includes steps such as material preparation and verification, housing unit assembly, auxiliary unit installation, closing and opening unit assembly, main shaft unit assembly, vacuum interrupter installation, and secondary circuit assembly.

The testing process covers visual inspection, mechanical characteristic testing, withstand voltage testing, loop resistance testing, vacuum degree testing, and operational characteristic testing.

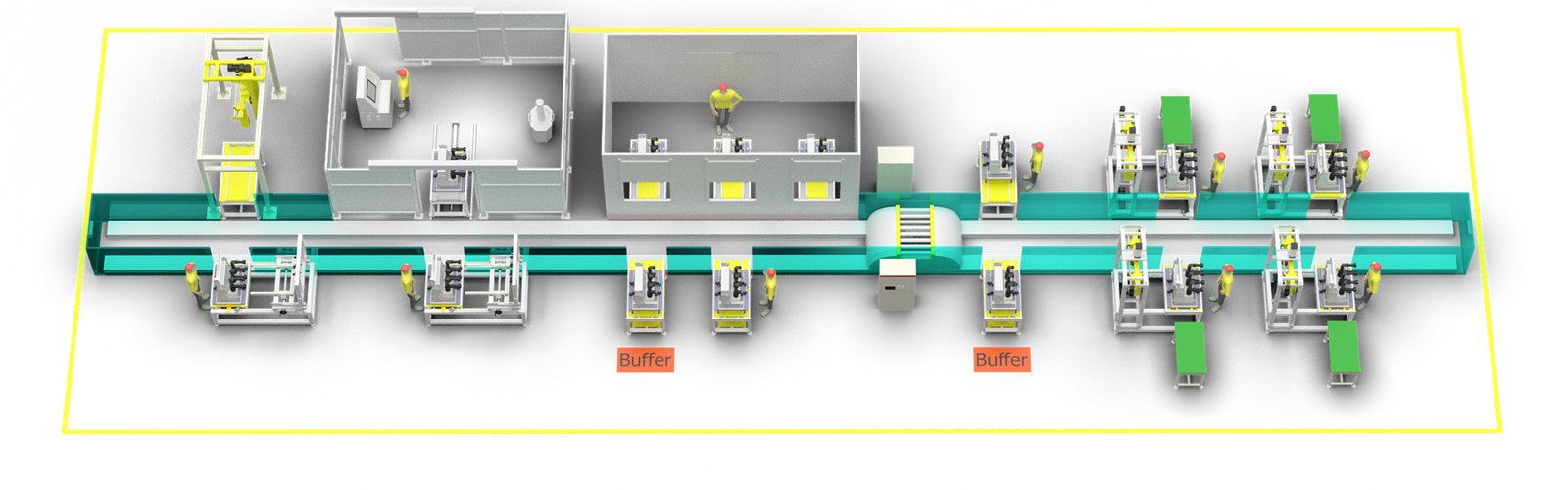

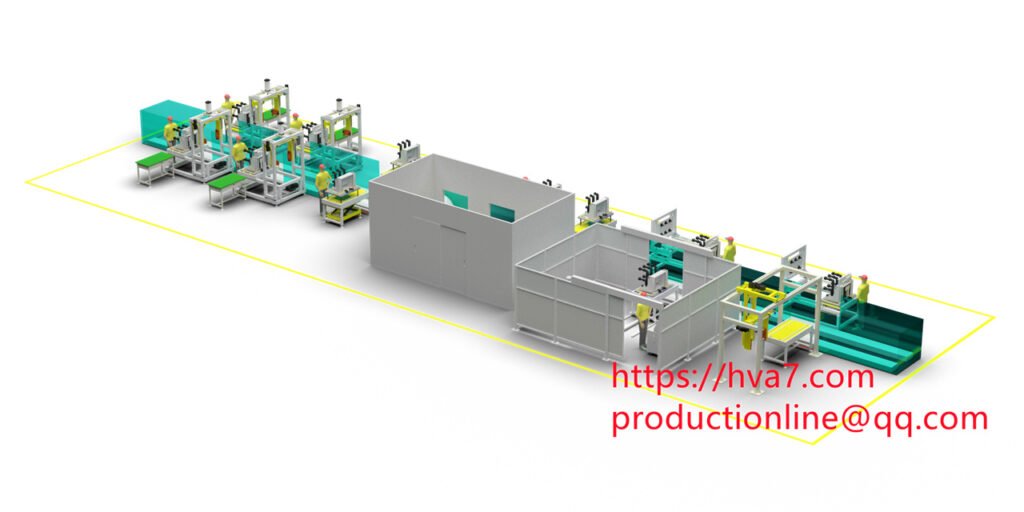

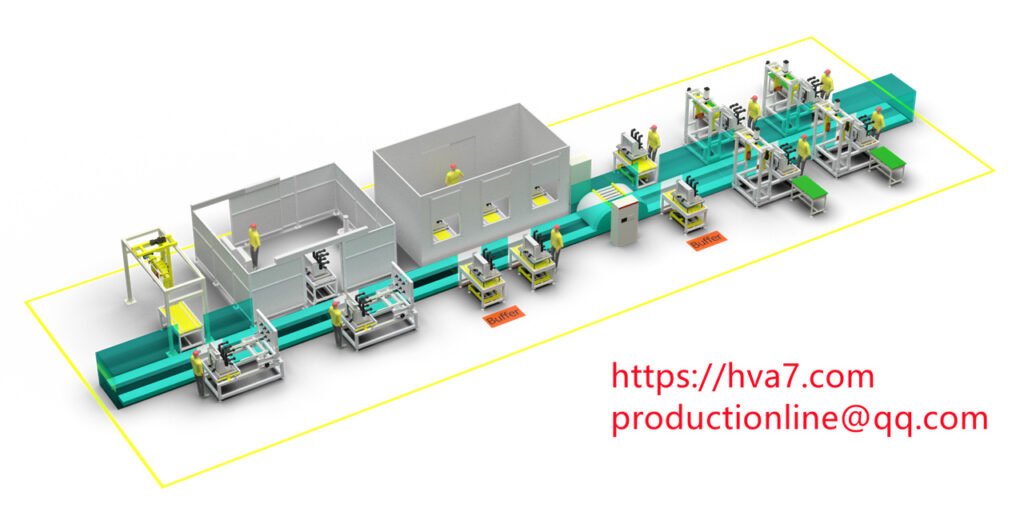

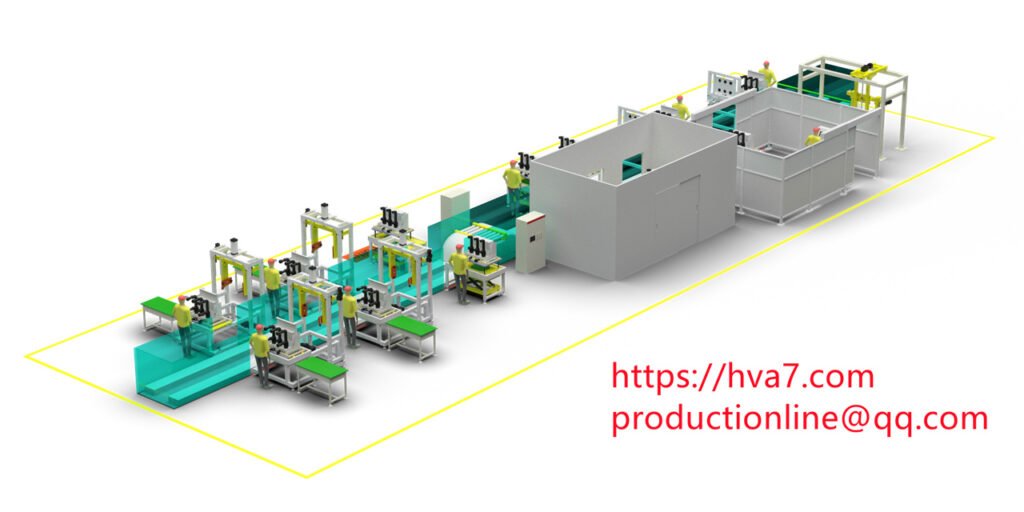

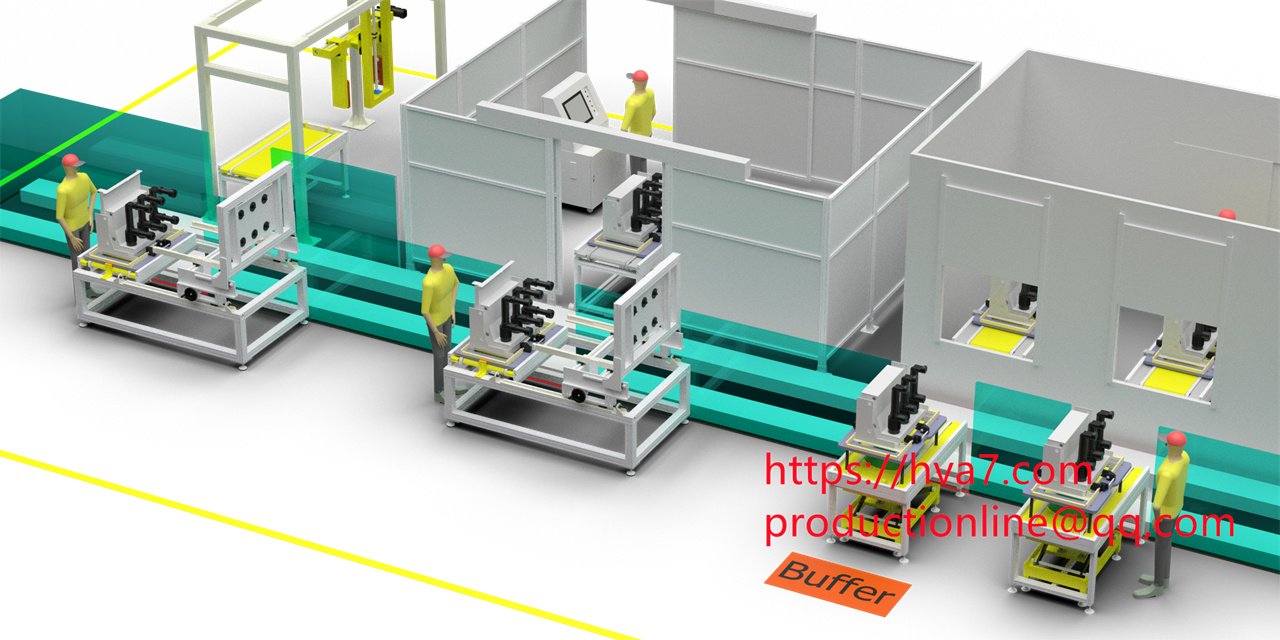

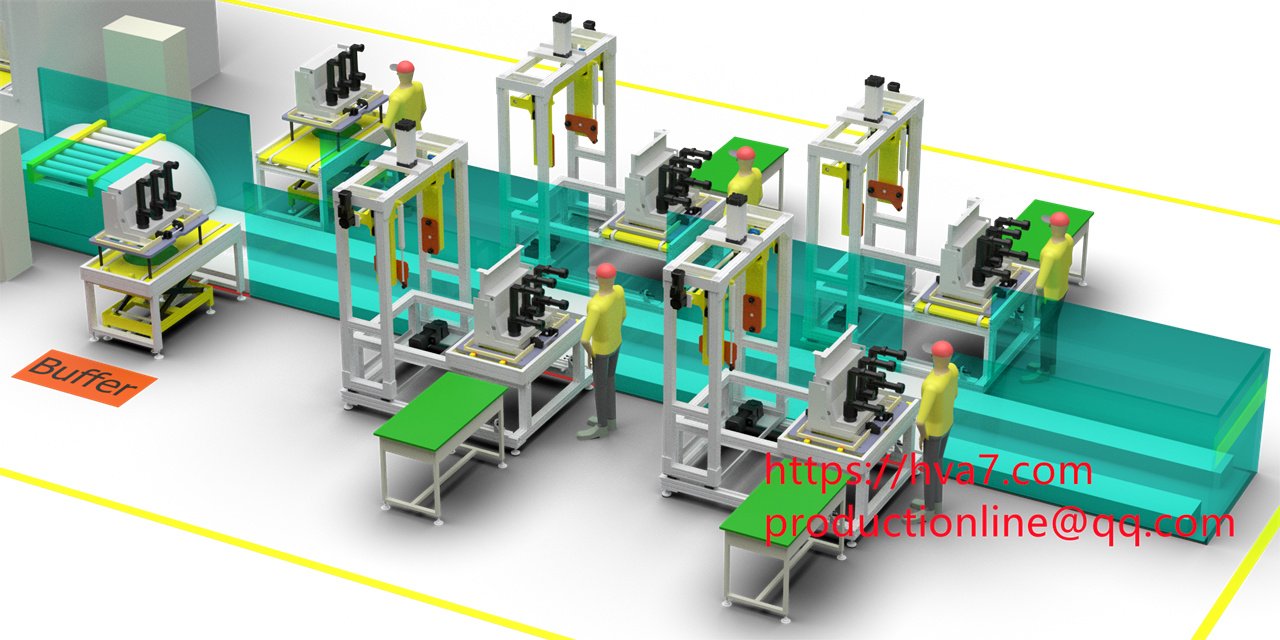

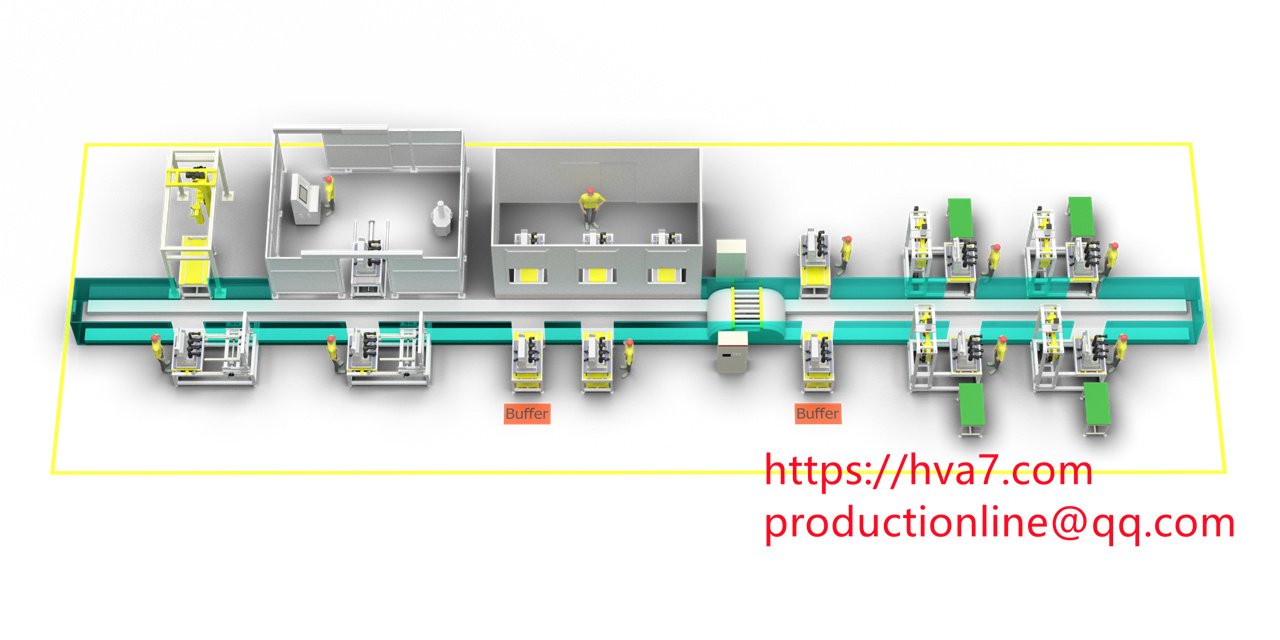

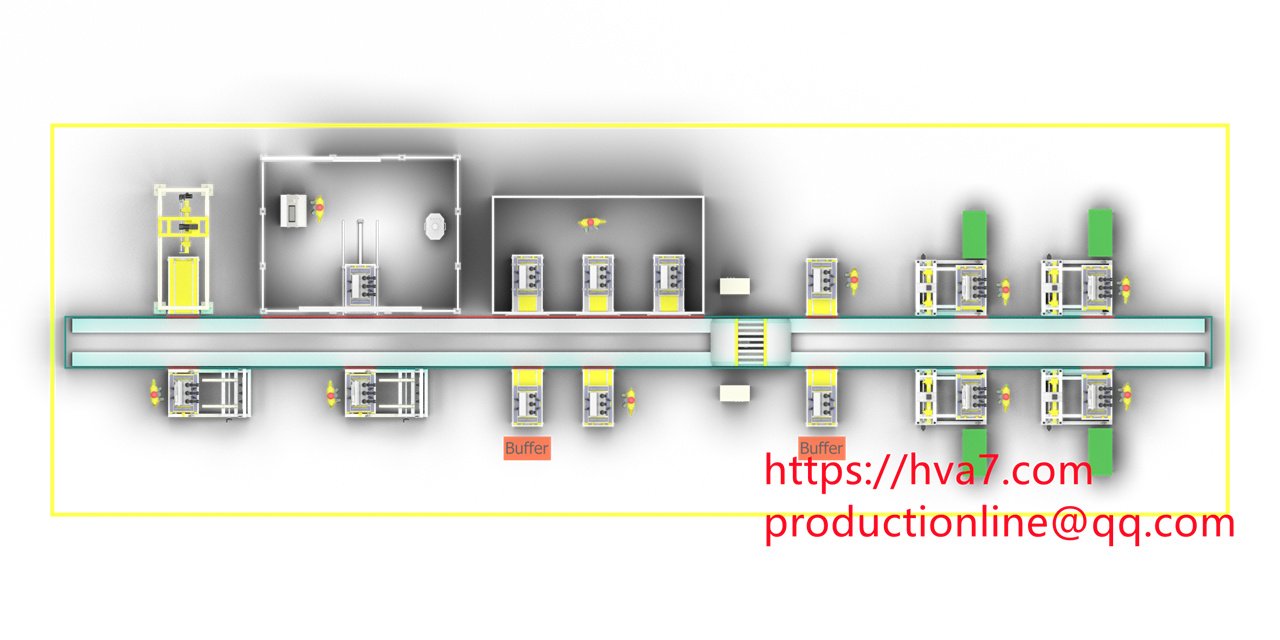

3.Automated Production Line:

The automated production line is designed with modularity to enhance product versatility and meet personalized requirements.

PLC is used as the field control unit, communicating with the upper computer in real-time via Ethernet.

Assembly is carried out in a cleanroom environment to ensure product cleanliness.

The production line integrates performance testing systems, vacuum degree testing systems, and withstand voltage testing systems to ensure product quality.

4.MES System:

The MES system is networked with the ERP system for real-time monitoring and management of the production process.

The system features automatic power frequency and impulse withstand voltage equipment, as well as specialized internal pressure measurement processes.

It has functions for quality traceability, barcode recognition, component life monitoring, and data storage.

It can be equipped with an intelligent energy analysis and energy-saving management system, as well as a smart equipment service big data cloud platform.

Through these advanced structural designs, processes, automated production lines, and MES systems, the VS1 vacuum circuit breaker ensures high performance and reliability, meeting the demands of power systems.