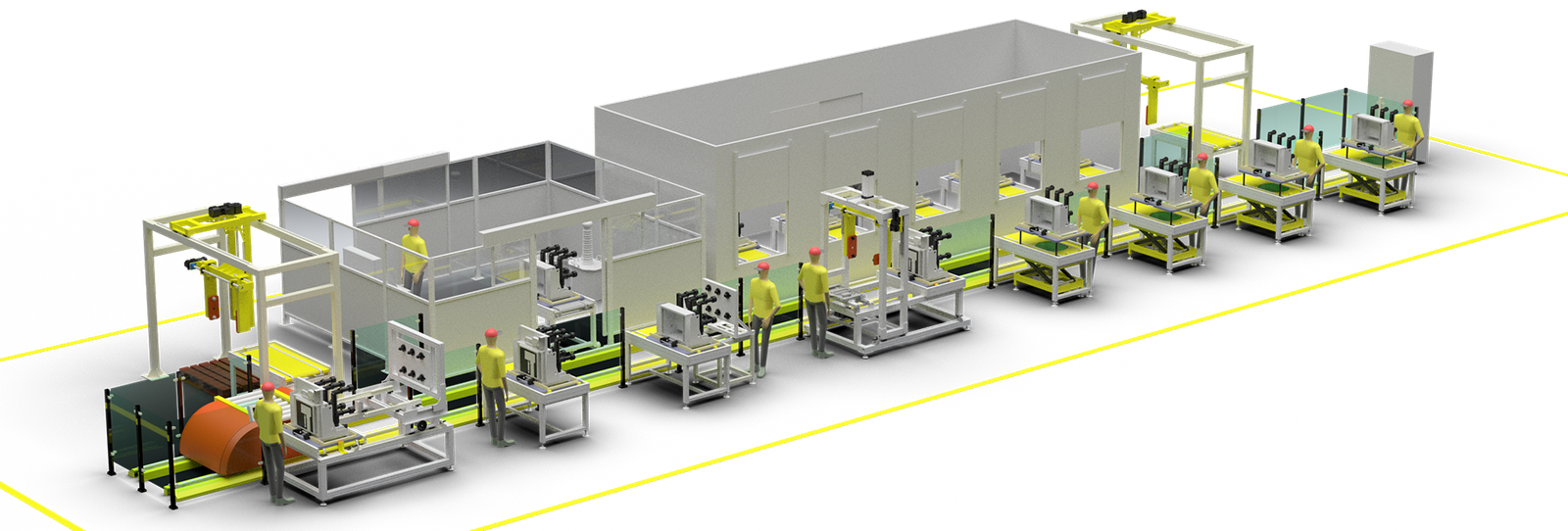

The VCB production line for vacuum circuit breakers can improve production efficiency, ensure operational safety, ensure product quality, and reduce costs.

- Automated assembly station: The assembly line may include multiple automated stations for precise assembly of various components of circuit breakers, such as contacts, arc extinguishing chambers, spring mechanisms, etc.

- Robot technology: Using industrial robots for component handling, positioning, and assembly to improve assembly accuracy and efficiency.

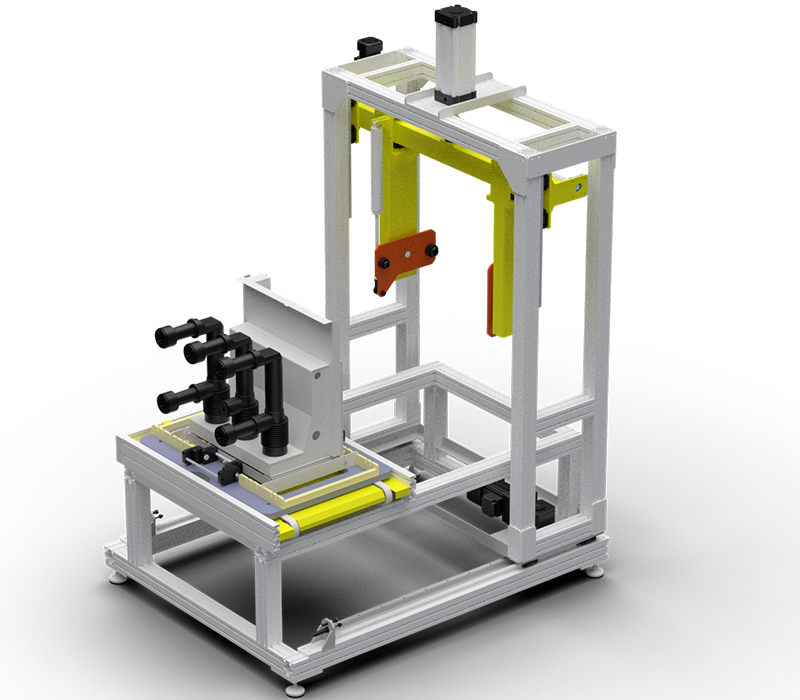

- Torque control system: an automatic or semi-automatic screw tightening device equipped with a torque control system to ensure that all screws at fastening points can be tightened according to the preset torque value.

- Quality inspection equipment: The assembly line may be equipped with automated inspection equipment, such as X-ray detection systems, insulation resistance testers, etc., to test the electrical performance and structural integrity of the assembled vacuum circuit breaker.

- Environmental control: Due to the high requirements for environmental cleanliness during the assembly of vacuum circuit breakers, the assembly line may include a clean room or enclosed assembly area to control dust and pollutants.

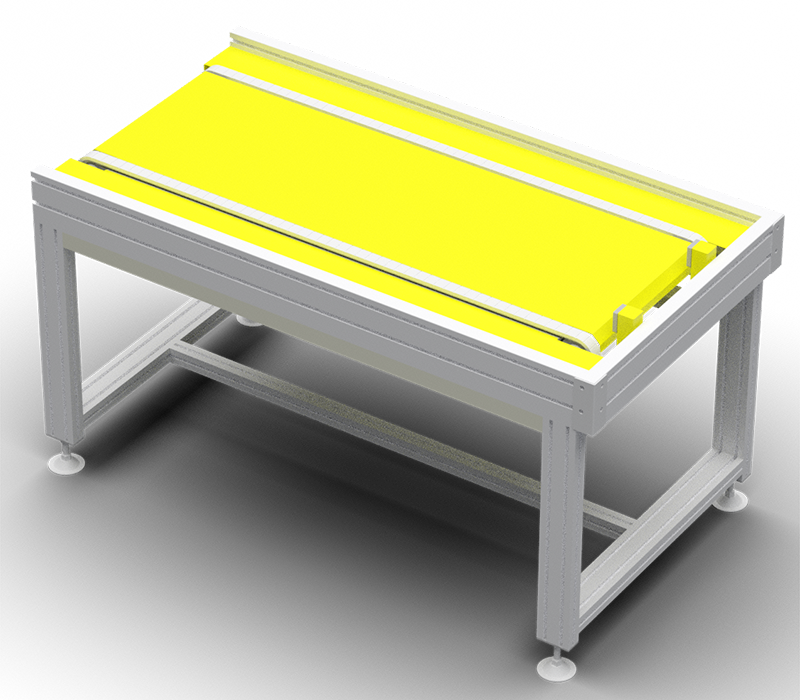

- Integrated conveying system: Use conveyor belts or roller lines to move the vacuum circuit breaker components from one station to another, ensuring the continuity of the assembly process.

- Safety system: The assembly line design will include multiple safety measures, such as emergency stop buttons, safety barriers, etc., to protect the safety of operators.

8.Data tracking and feedback system: The assembly line may integrate a data tracking system to record the assembly parameters and test results of each vacuum circuit breaker for quality control and traceability.

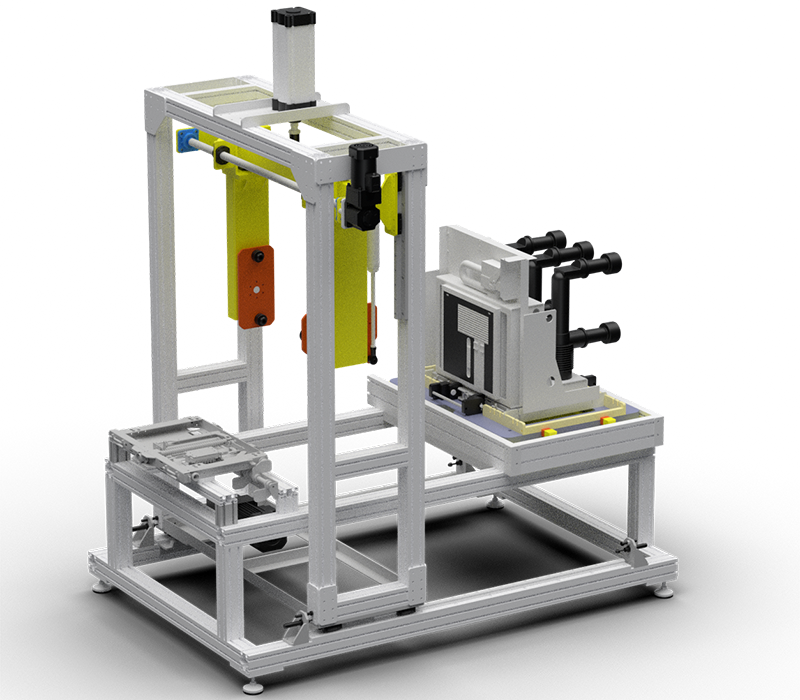

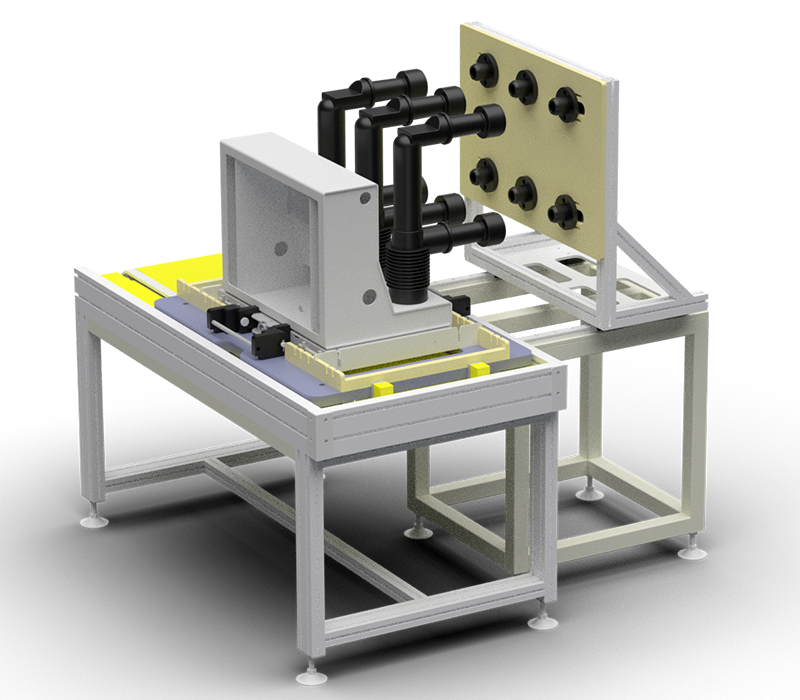

Modular equipment for VCB assembly: M01–M03

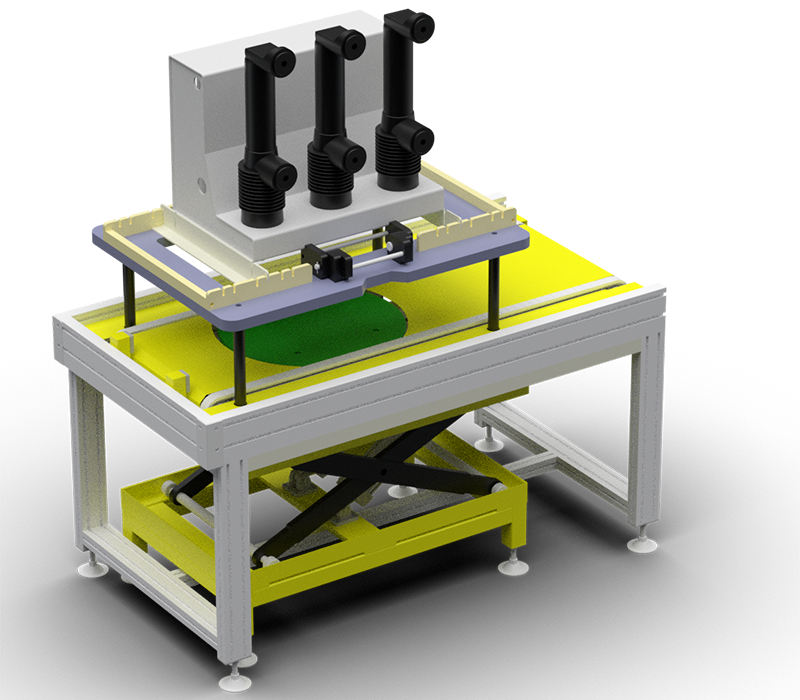

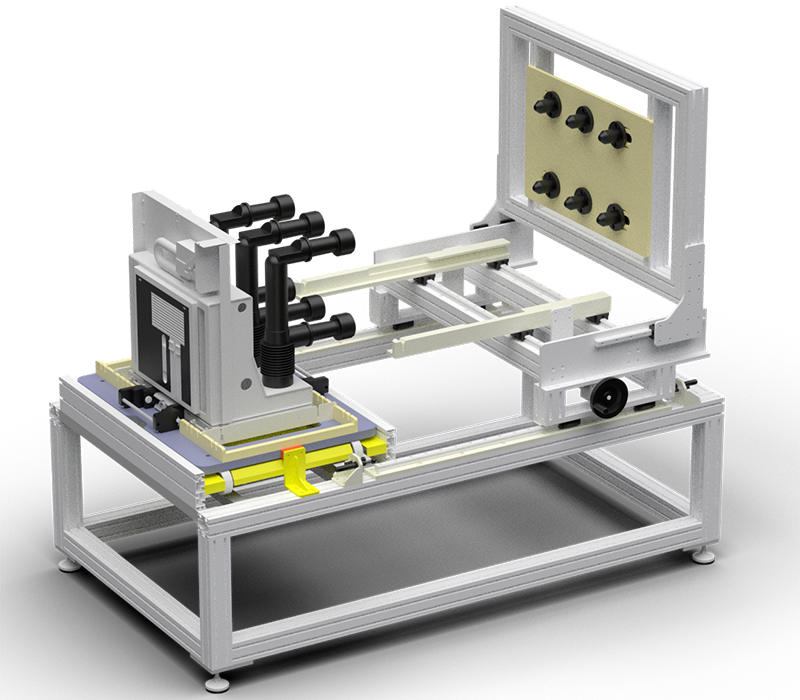

Modular equipment for VCB assembly: M04–M06

VCB assembly lines