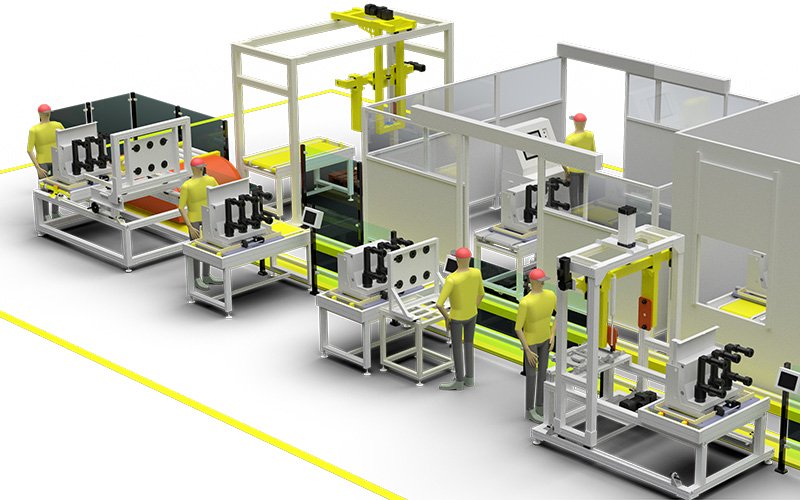

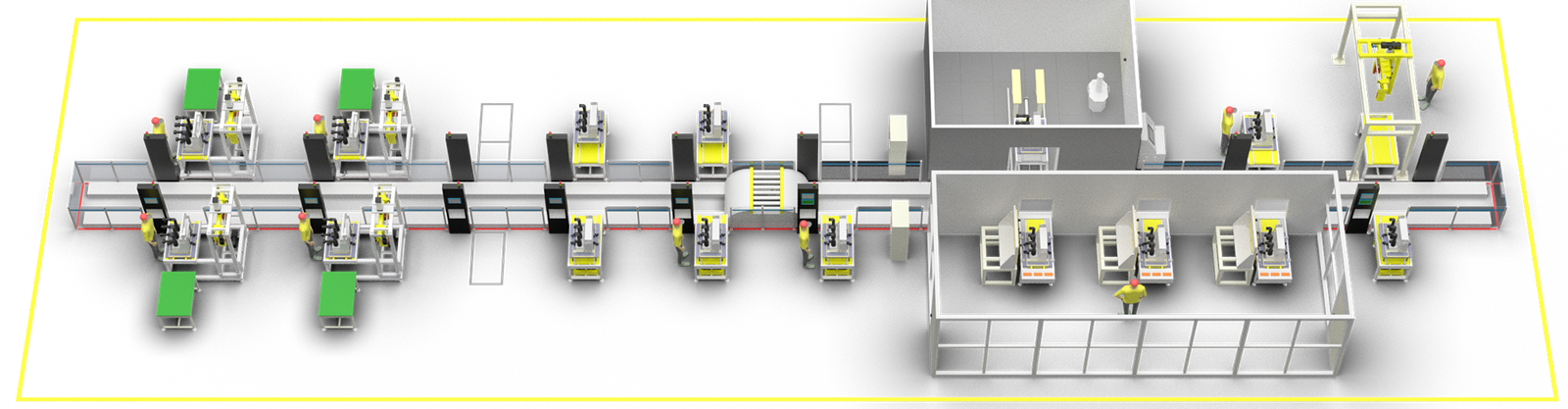

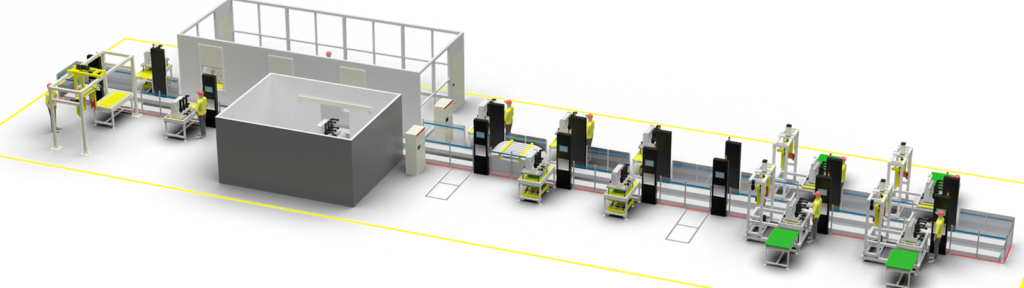

VCB Assembly Line

The assembly process of vacuum circuit breakers (VCB) involves precise manufacturing steps to ensure product quality and performance. The process begins with the preparation of raw materials, including copper, insulation components, and alloy contacts. These materials are precisely processed by CNC machine tools to form the key components of circuit breakers. Subsequently, the components enter the automated assembly line and are precisely assembled through production lines and fixed fixtures. After assembly, the vacuum circuit breakers (VCB) undergoes a running in test and mechanical characteristic adjustment. Continuing with a series of electrical tests, such as voltage withstand tests and operational tests, to verify its performance. Finally, qualified products undergo final inspection, packaging, and preparation for shipment. The entire process emphasizes precision and quality control to ensure the high reliability and safety of vacuum circuit breakers (VCB).

The assembly line is suitable for:

Mass and standardized assembly production of vacuum circuit breakers (VCB)

Note: There are differences in the structure of vacuum circuit breakers from different brands, and the layout of the production line will change with the production process. For more solutions, please contact our engineers.

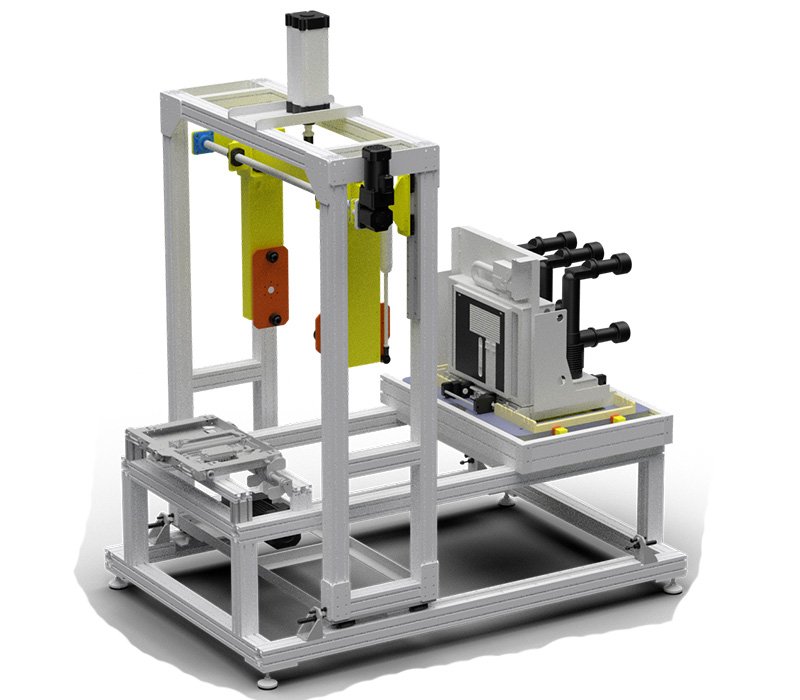

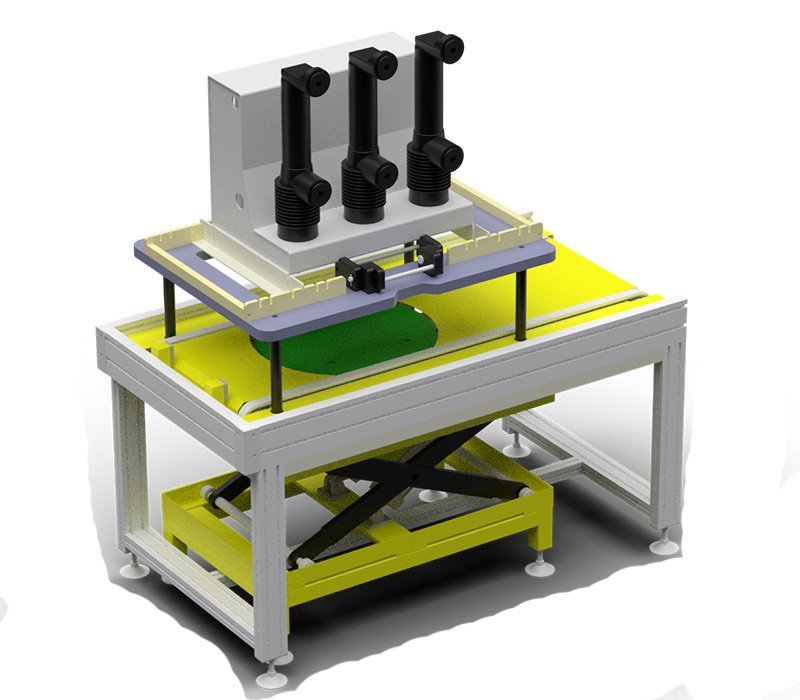

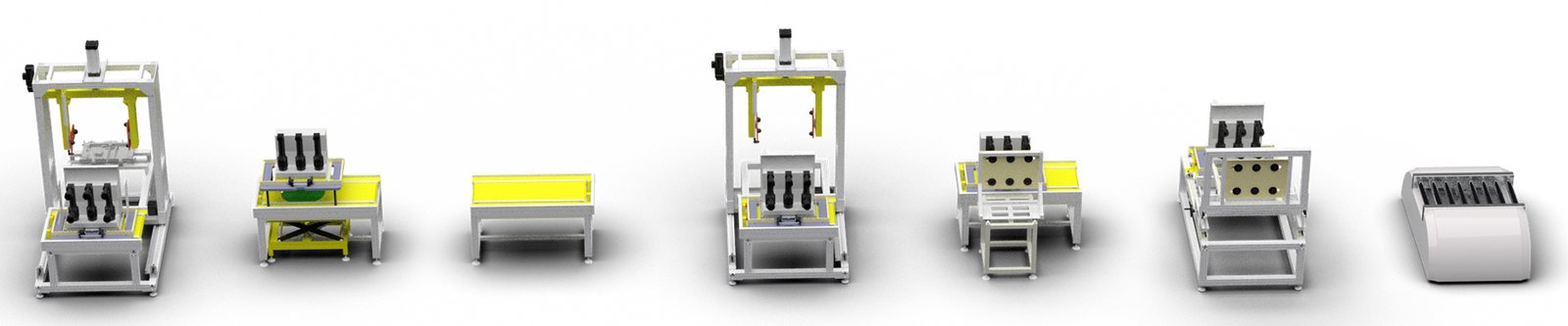

Modular production equipment for vacuum circuit breakers

Build a customized vacuum circuit breaker production line through our modular components. We insist on providing you with efficient and high-quality automation equipment. From design to manufacturing, we insist on selecting high-quality components. In the past few decades, we have become high-quality partners for numerous manufacturers of high-voltage electrical products.

Relevant references for vacuum circuit breaker production lines

Vacuum circuit breaker (VCB) Assembly line Video