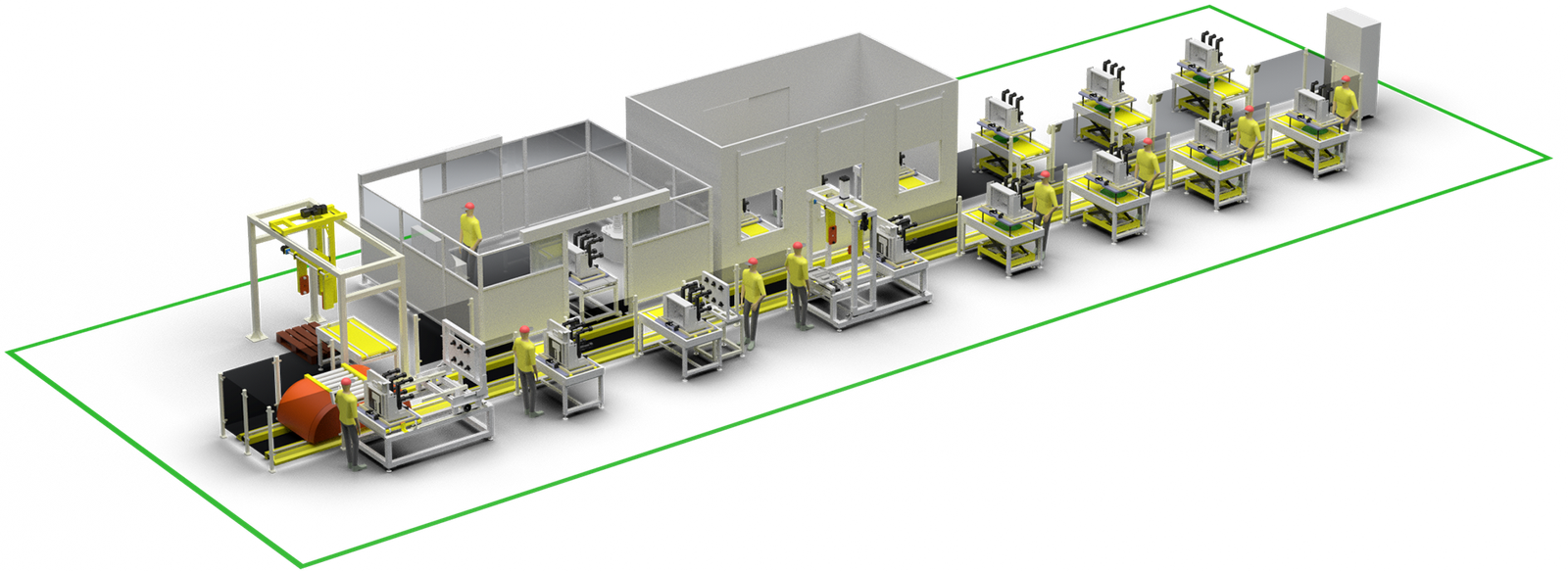

The vacuum circuit breaker (VCB) production line is a highly digitized and intelligent production system. After receiving instructions from the control panel, the rail shuttle car will automatically operate across workstations and transfer the product to the next process. The entire process includes installation, running in, debugging, testing, and repair, all in one go. Compared to traditional production lines, intelligent production lines not only liberate workers from busy production, but also improve product quality and production efficiency, achieving standardized production of products.

Vacuum circuit breaker production line – Video

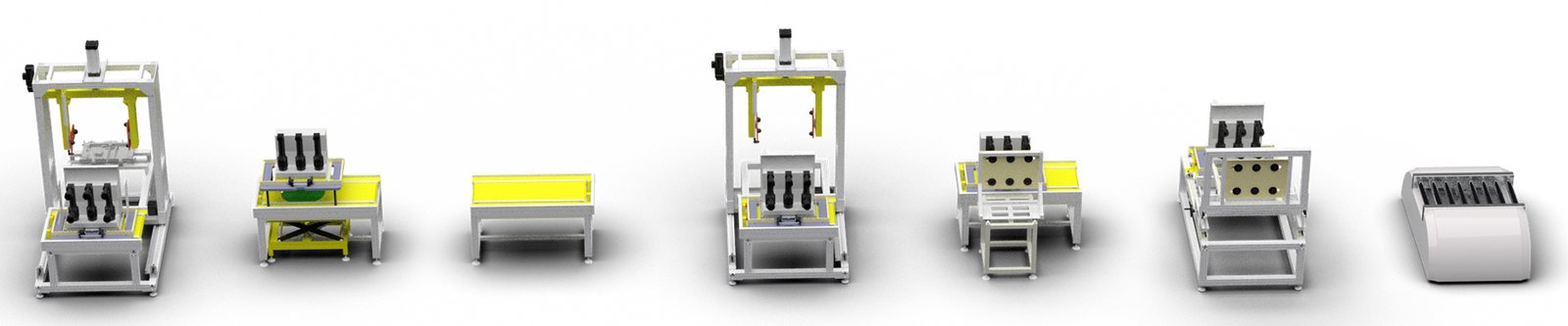

Modular design of vacuum circuit breaker production line

Testing equipment for vacuum circuit breaker production

1.Vacuum Circuit Breaker (VCB) Break-in Test Equipment

Mechanical characteristic testing includes testing the closing and opening time of the vacuum circuit breaker; Hard opening and closing speed; Closing and opening curves, three-phase with different periodicity; Three phase travel; Bounce time, overshoot, rebound amplitude; Fracture opening distance and overtravel; Parameters such as average speed of opening and closing. The mechanical characteristics of vacuum circuit breakers will truly reflect the performance level of vacuum circuit breakers. Accurate testing should be carried out before leaving the factory to ensure that all data is correct and free of deviations. This is the key to the circuit breaker’s ability to carry the rated working current, make and break the rated short-circuit current.

2.Automatic equipment for final inspection of vacuum circuit breakers

Complete factory inspection items such as opening and closing control and interlocking testing, circuit resistance testing, grounding resistance testing, secondary circuit wiring correctness testing, and secondary line power frequency withstand voltage testing to ensure product quality and reliable performance.

The automated testing equipment and docking device are integrated into the assembly line. It can achieve efficient docking between the detection station and the main conveyor line.

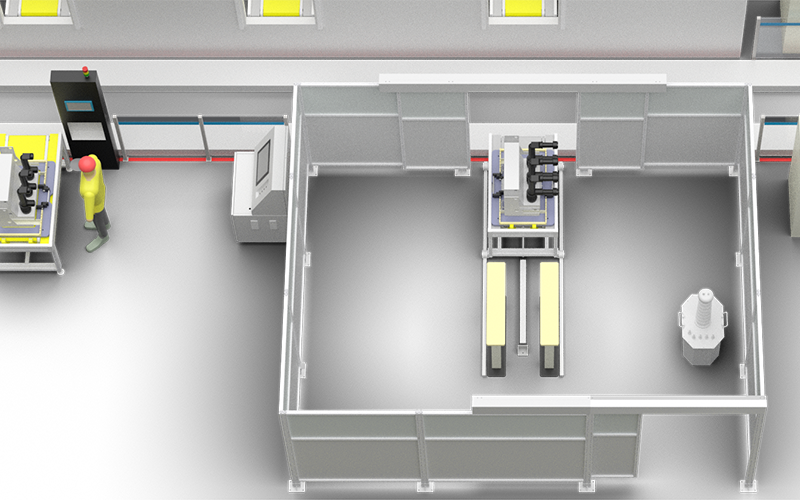

3.VCB power frequency withstand voltage testing equipment

To test the insulation performance of vacuum circuit breakers, a voltage withstand test is conducted on the ground, phase to phase, and fracture of the primary circuit. When the circuit breaker is in the disconnected state, a certain power frequency voltage is applied between the moving and stationary contacts to detect the magnitude of the leakage current and the discharge phenomenon in the arc extinguishing chamber, thereby determining whether the vacuum degree of the vacuum arc extinguishing chamber meets the requirements. The magnitude of vacuum degree will directly affect the arc extinguishing performance of vacuum circuit breakers, and a decrease in vacuum degree will cause adverse consequences to the operation of vacuum circuit breakers. Therefore, detecting the vacuum degree of the vacuum arc extinguishing chamber is an important guarantee for the reliable operation of the vacuum circuit breaker.