Utilizing an automated production line for the assembly, production, and testing of RM6 ring network cabinets offers numerous benefits: Firstly, it significantly increases production efficiency, reduces manual operations, and shortens production cycles. Secondly, automation ensures consistent and reliable product quality, reducing human error. Moreover, precision processes such as robotic welding and helium leak detection enhance product accuracy and safety. The automated production line also achieves information management, making the production process more transparent and easier to track and manage. Lastly, through customized and flexible design, the production line can adapt to different product requirements, improve market response speed, and reduce production costs, thereby enhancing the competitiveness of the enterprise.

The RM6 ring network cabinet is a type of high-voltage switchgear typically used in ring distribution networks. Here is the information on the RM6 ring network cabinet’s structure, assembly and testing process, robotic welding, helium leak detection, and automated assembly production line:

1.Structure of the Ring Network Cabinet:

The ring network cabinet consists of four parts: the switch chamber, fuse chamber, operating mechanism chamber, and cable chamber (base frame).

The switch chamber is made up of various functional circuits sealed within a metal casing, including the busbars between them, typically welded from cold-rolled steel or stainless steel plates.

The load switch uses a pressurized gas blowing structure, which has strong arc-quenching capabilities.

The fuse and load switch form a transformer protection circuit, with the high-voltage current-limiting fuse housed in an insulating casing.

The operating mechanism chamber, located at the front of the ring network cabinet, is equipped with manual or electric energy storage spring operating mechanisms.

2.Assembly and Testing Process:

Part preparation: Prepare the necessary parts and components.

Assembly: Assemble the various parts of the ring network cabinet in a predetermined order and method.

Performance testing: Conduct high-frequency withstand voltage tests, lightning impulse tests, and partial discharge tests on the assembled ring network cabinet.

Gas chamber leak detection: Ensure the gas tightness of the ring network cabinet to prevent leakage of insulating gas.

Withstand voltage and other tests: Perform high-frequency withstand voltage tests to verify the insulation strength of the ring network cabinet.

3.Robotic Welding:

The metal casing of the ring network cabinet is typically manufactured by welding cold-rolled steel or stainless steel plates to form a sealed switch chamber.

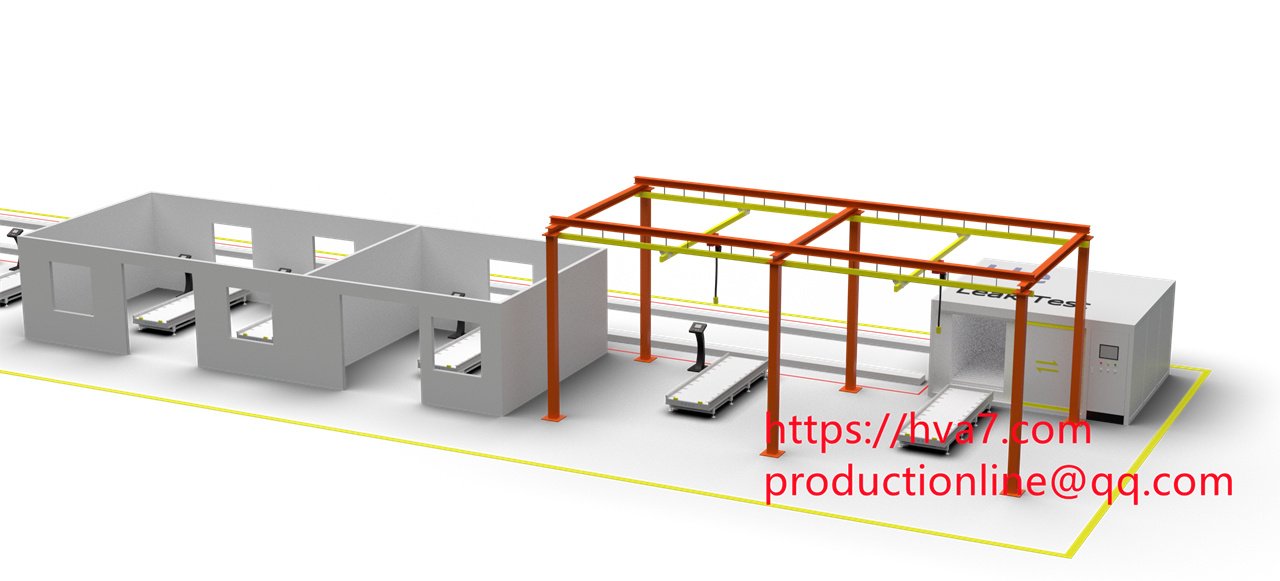

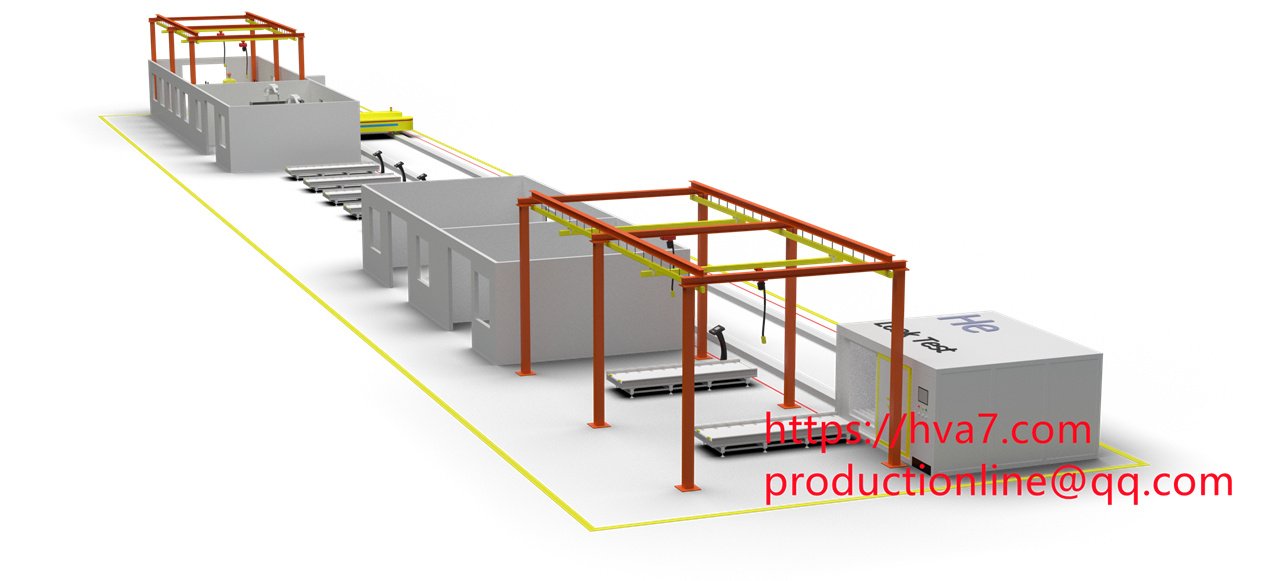

4.Helium Leak Detection:

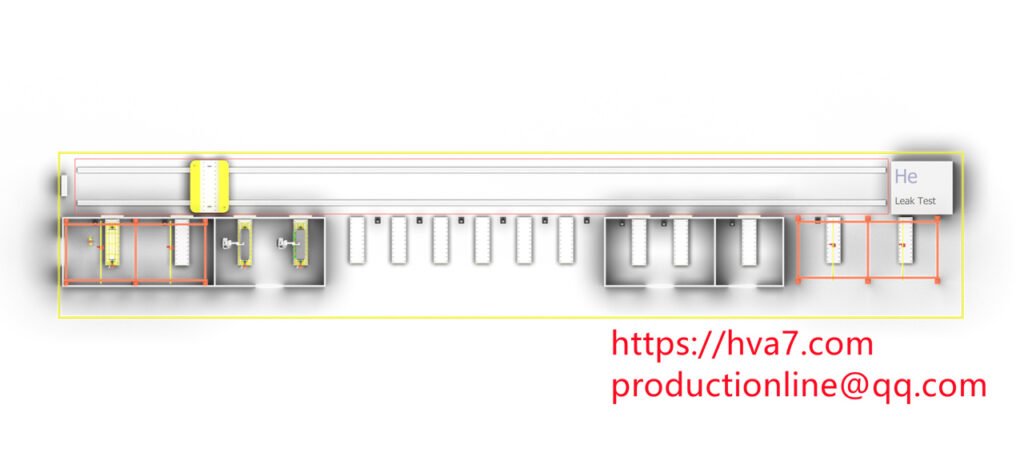

The ring network cabinet helium inspection equipment is an automated detection system designed specifically for the gas tightness testing of high-voltage ring network gas-filled cabinets in the power industry.

The equipment uses a vacuum chamber method and helium mass spectrometer leak detection technology, creating a pressure difference between the inside and outside by simultaneously evacuating, and then detecting leaks after charging the workpiece with helium.

The system has functions for large leak judgment and quantitative detection of micro-leaks, and can automatically recover and recycle helium gas.

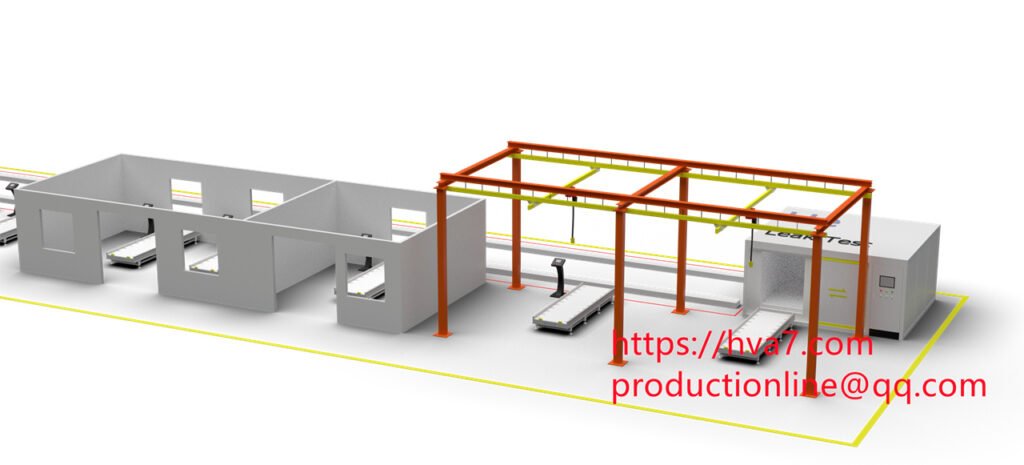

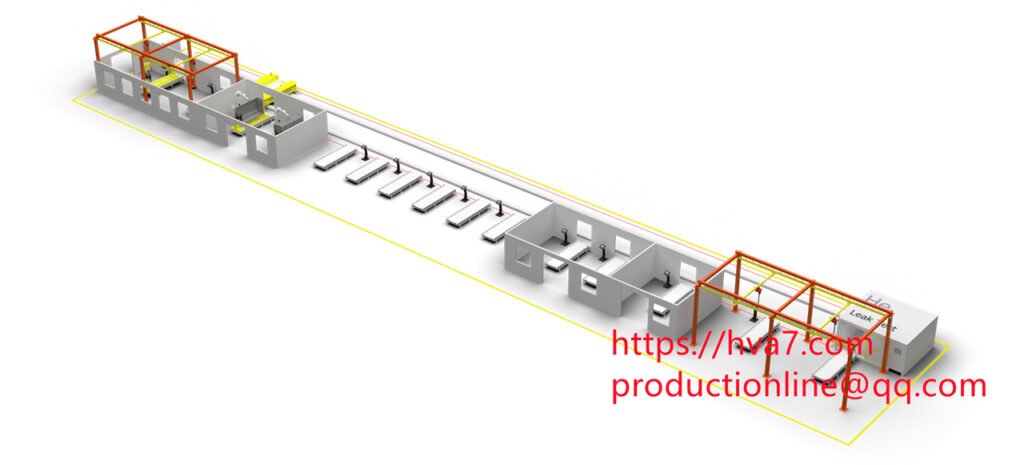

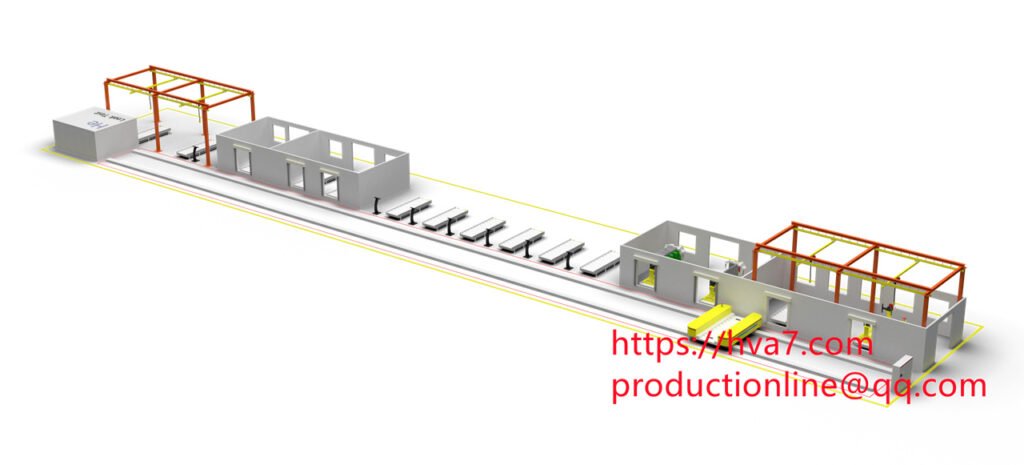

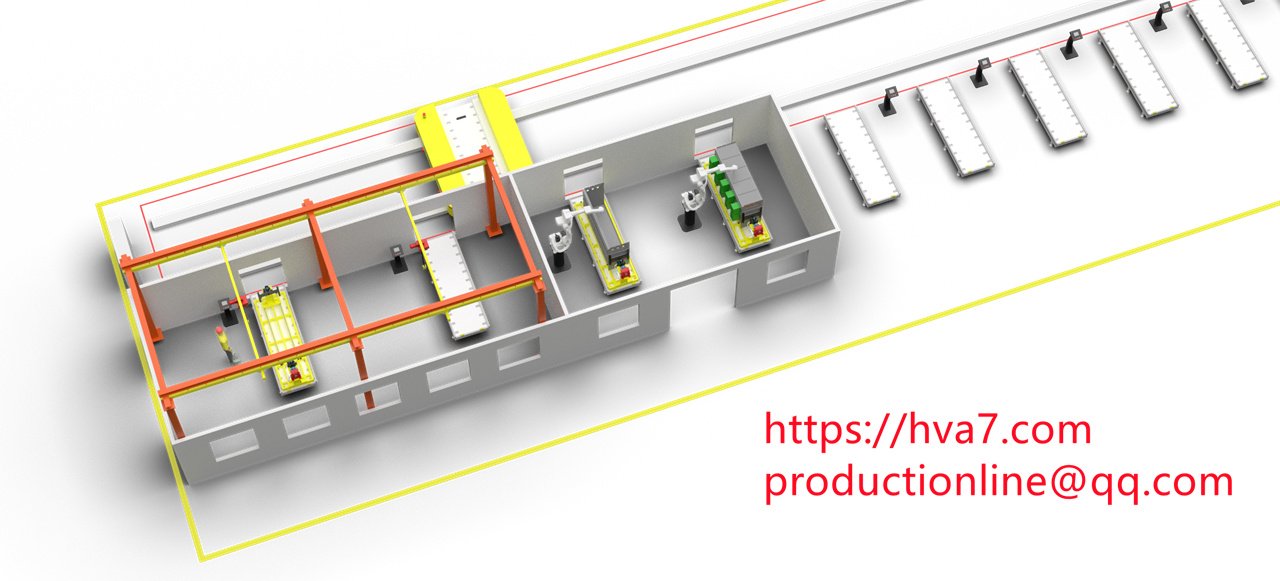

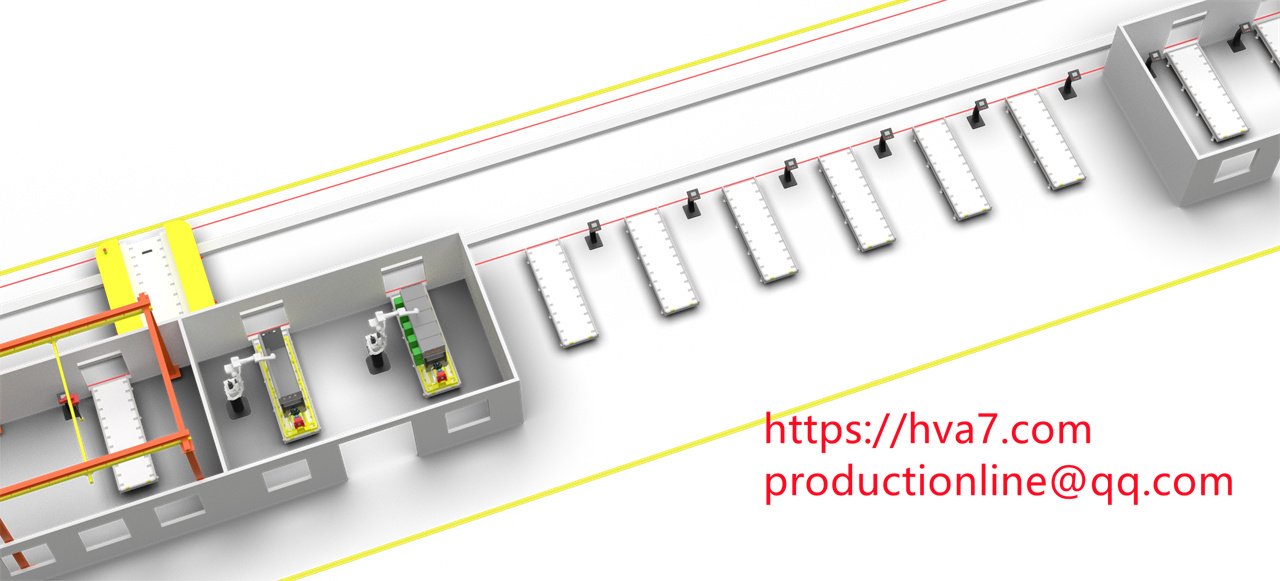

5.Automated Assembly Production Line:

The automated production line uses automated equipment and intelligent manufacturing systems to achieve a fully automated production process.

The production line integrates MES (Manufacturing Execution System) and material management systems to automatically transfer information and improve production efficiency.

Customized design: The production line can be customized and adjusted according to different product requirements.

Flexible production: The production line is designed with downgraded workstations, that is, manual repair workstations, to cope with the failure of automated equipment and ensure the continuity of production.

Quality control: Only products that pass the inspection will come off the line to ensure product quality.