Used for standardized assembly of Gas Insulated Switchgear (GIS)

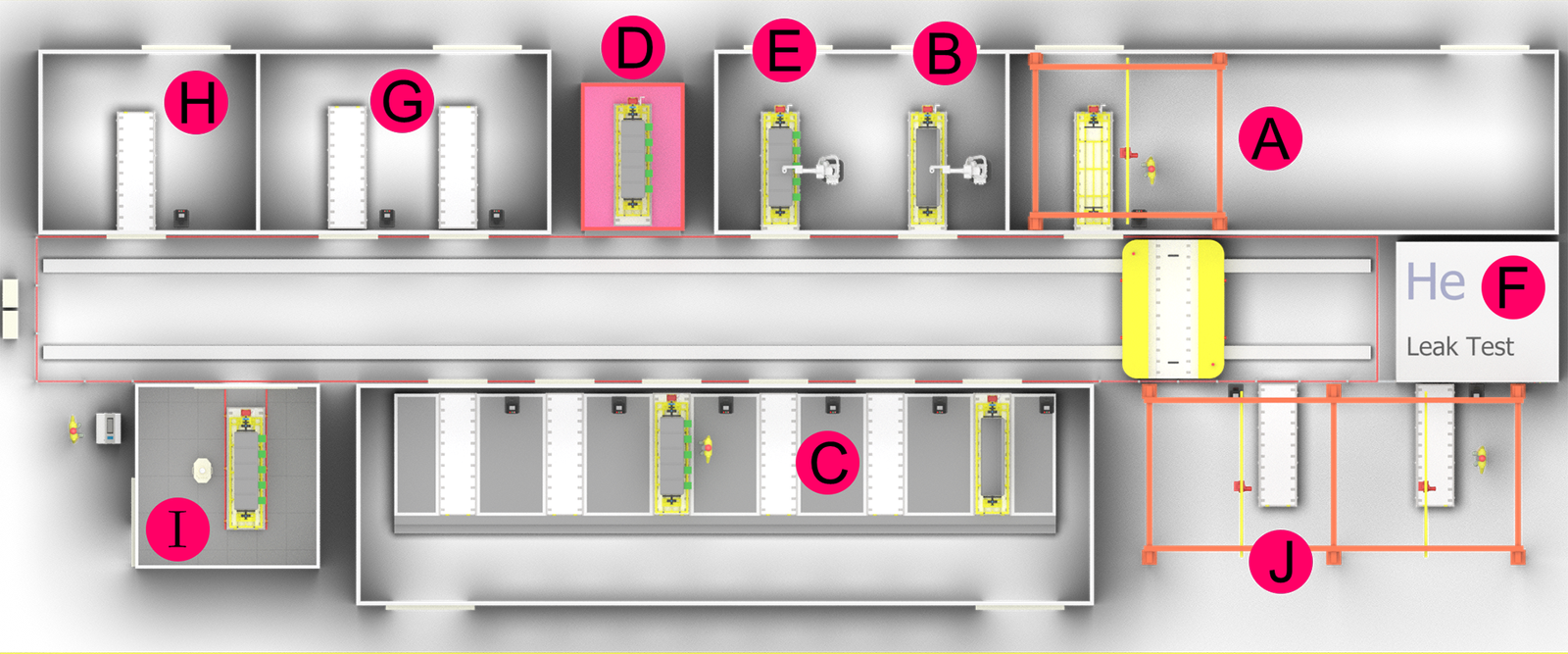

The gas insulated switchgear (GIS) assembly line includes sheet metal shell assembly and welding; Installation of electrical components, such as load switches, fuses, circuit breakers, etc.; Break-in test; Mechanical performance adjustment; Secondary welding of sheet metal; Helium leak detection; Power frequency withstand voltage test; Partial discharge testing; Secondary wiring; Complete assembly and packaging, etc.

Modular design, provide efficient and stable equipment service.

Reference process flow and related equipment for assembling Gas Insulated Switchgear (GIS)

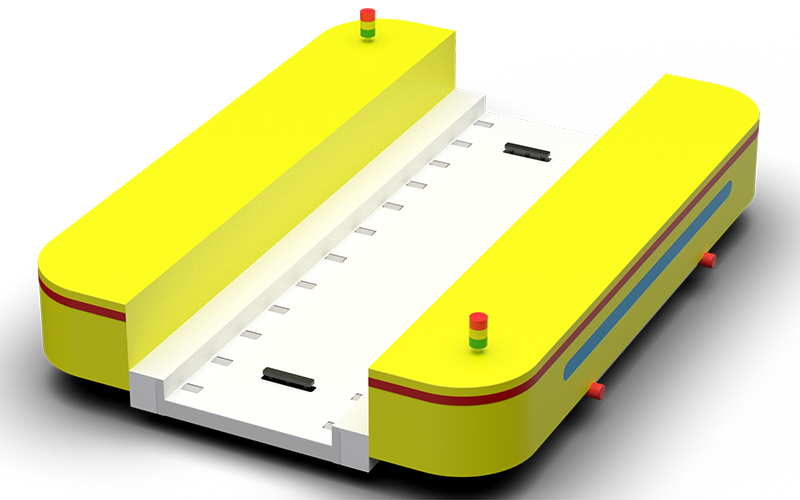

Gas Insulated Switchgear (GIS) sheet metal assembly and hoisting online

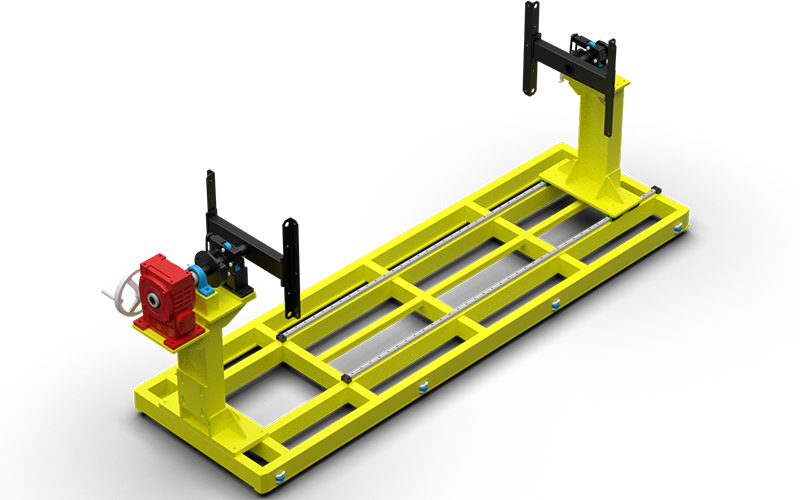

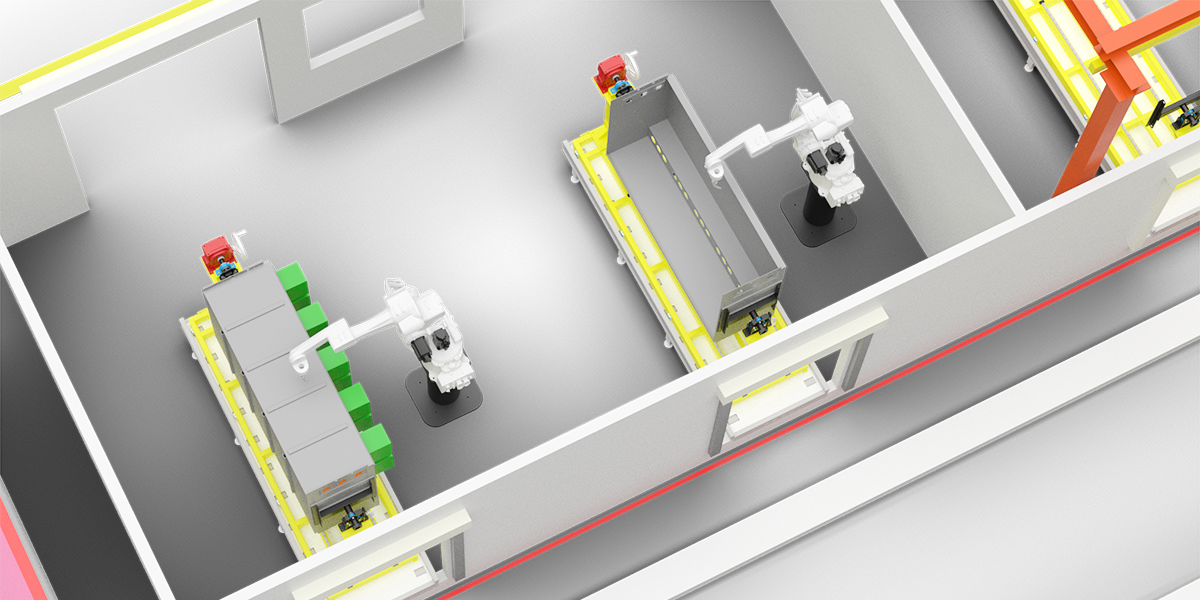

Robot automatic tracking welding Gas Insulated Switchgear (GIS)

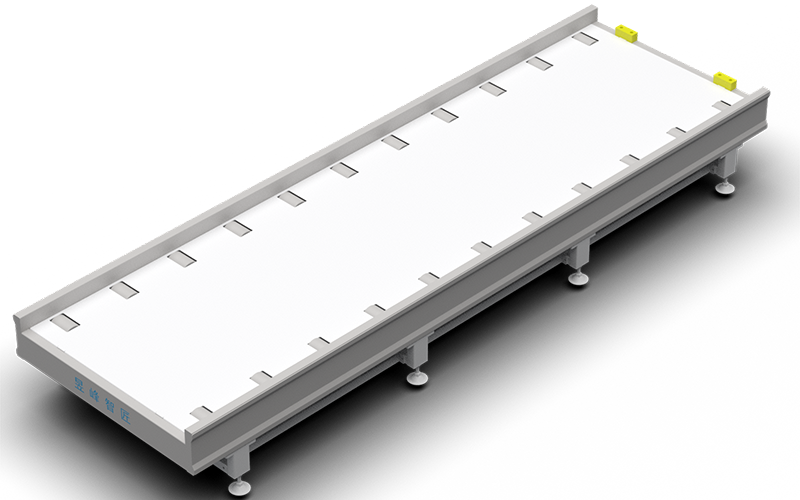

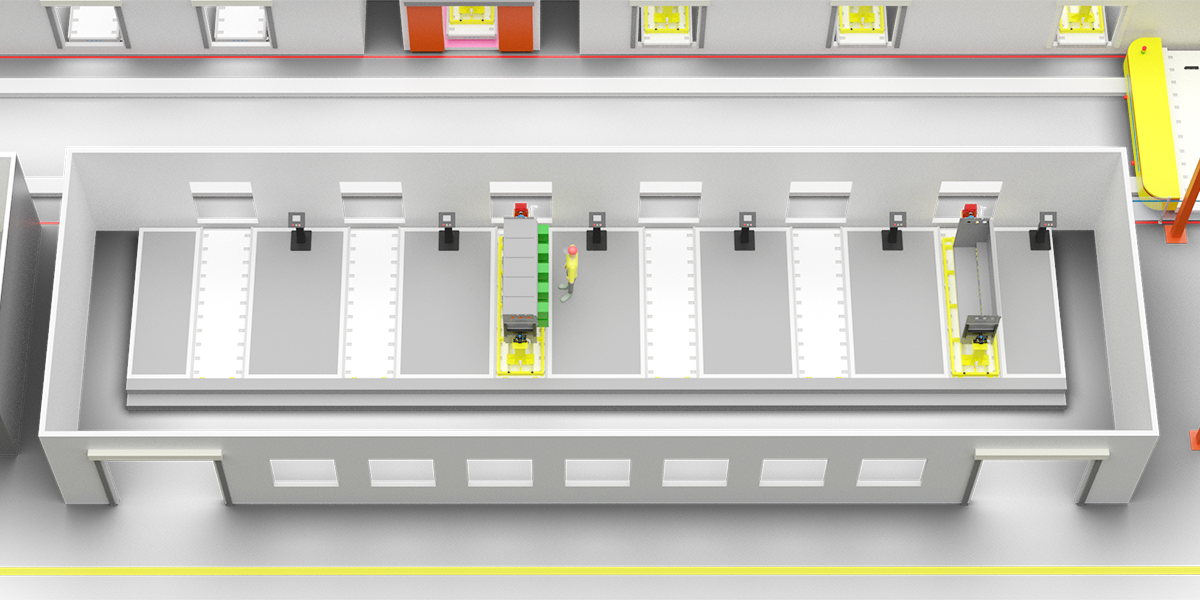

Installation of Electrical Components in Gas Insulated Switchgear (GIS)

Running in and mechanical characteristics of Gas Insulated Switchgear (GIS)

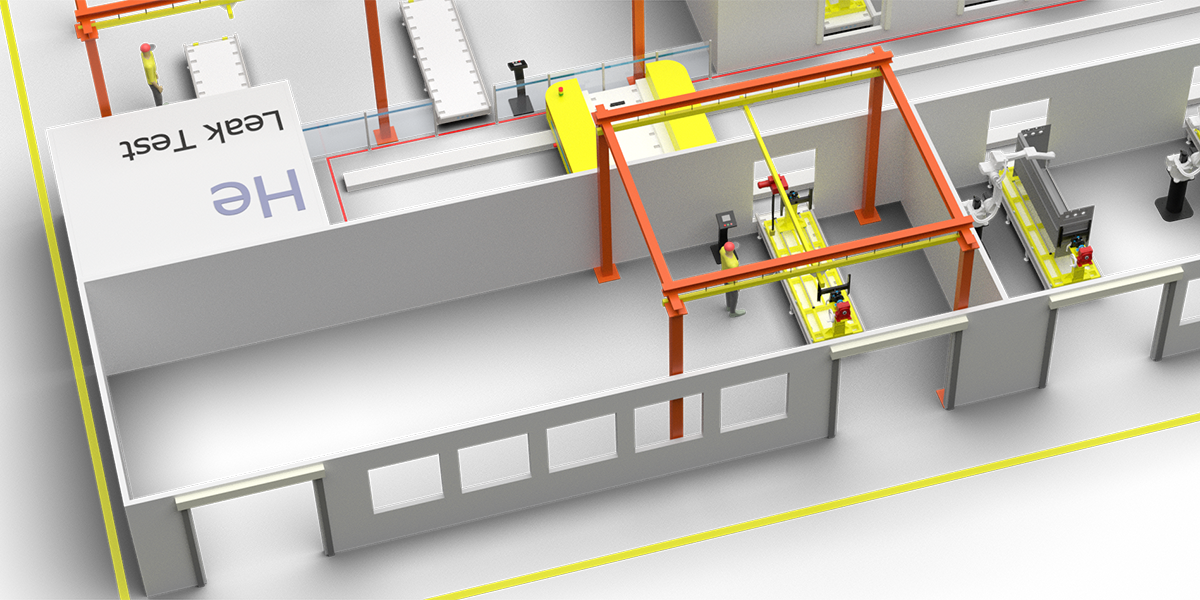

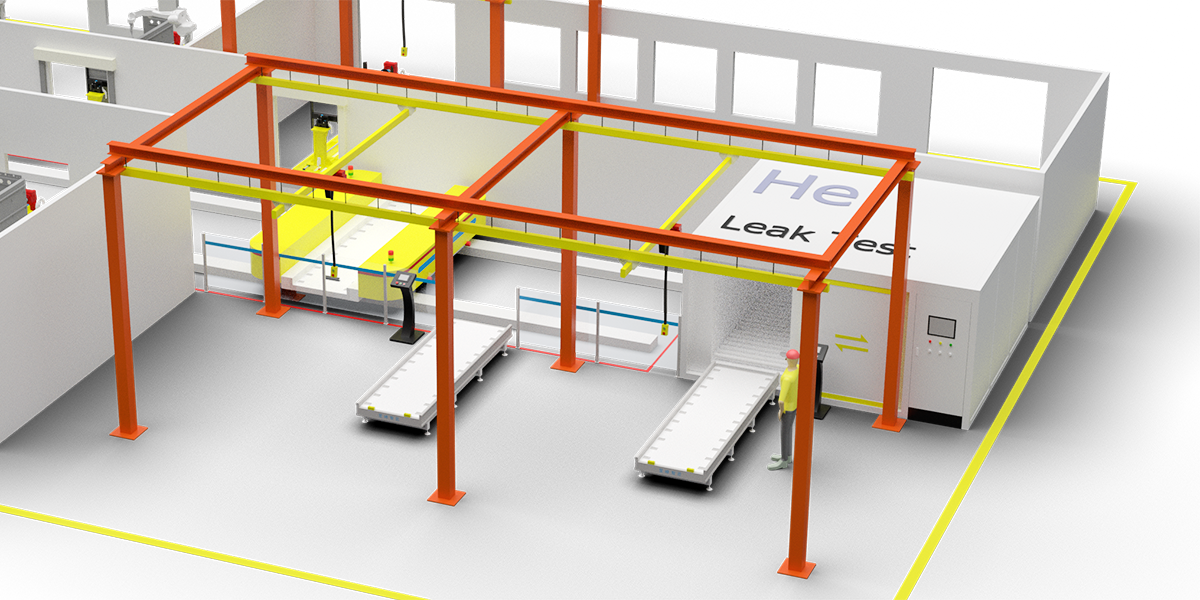

Helium gas testing for airtightness of Gas Insulated Switchgear (GIS)

Note: The product structure, production requirements, and production standards of each manufacturer are different, and the configuration and layout of assembly line equipment are also different. We insist on using high-quality components to build your Gas Insulated Switchgear (GIS) production system.