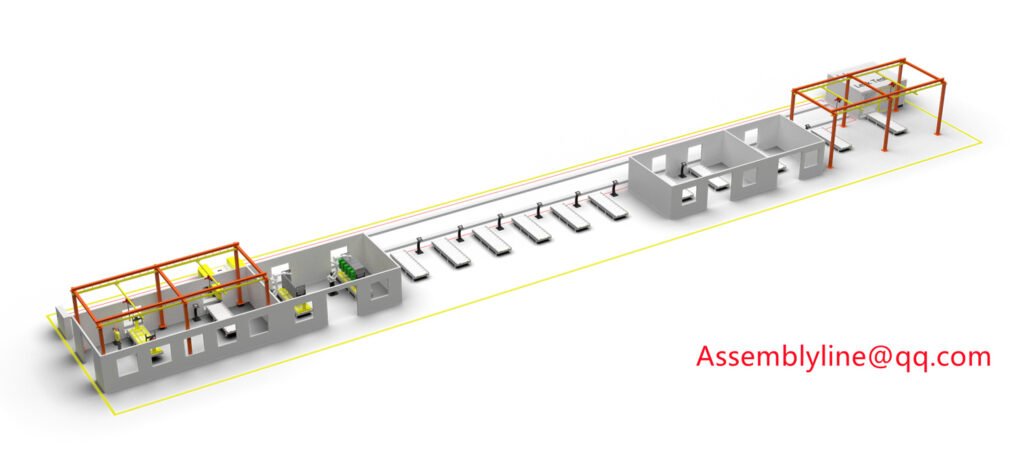

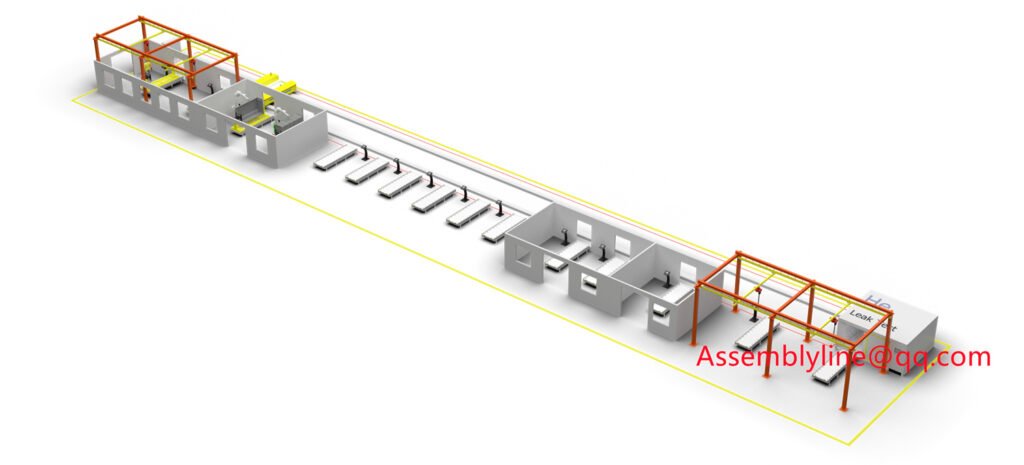

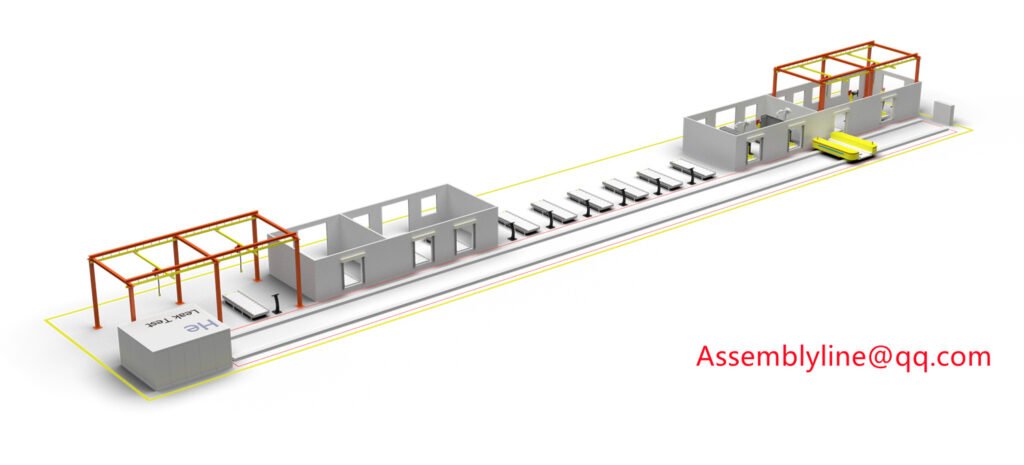

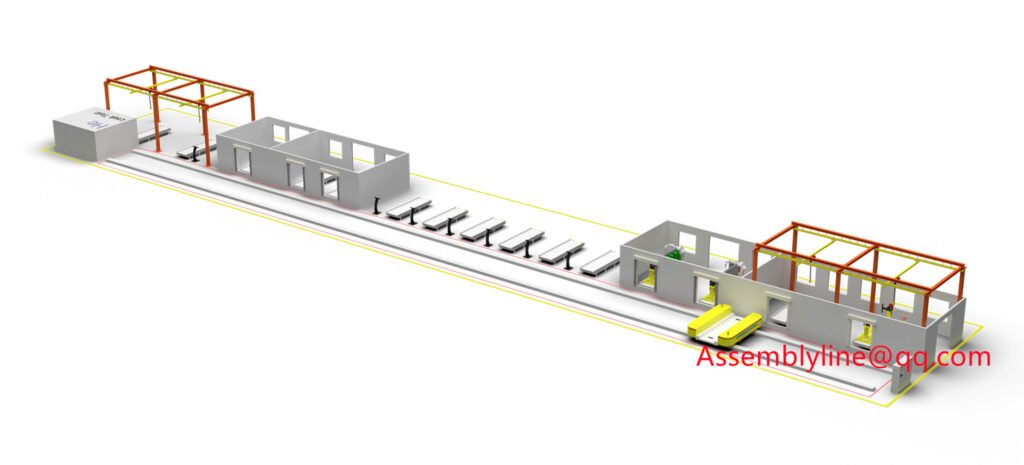

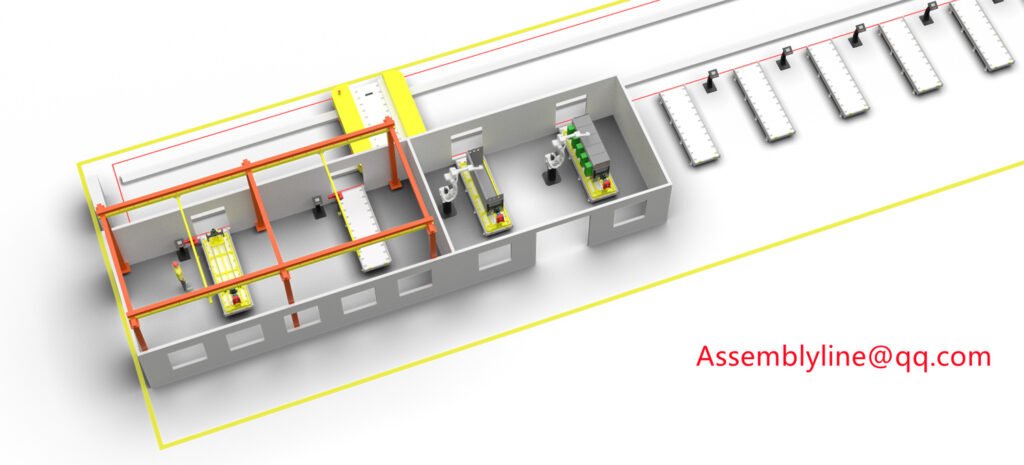

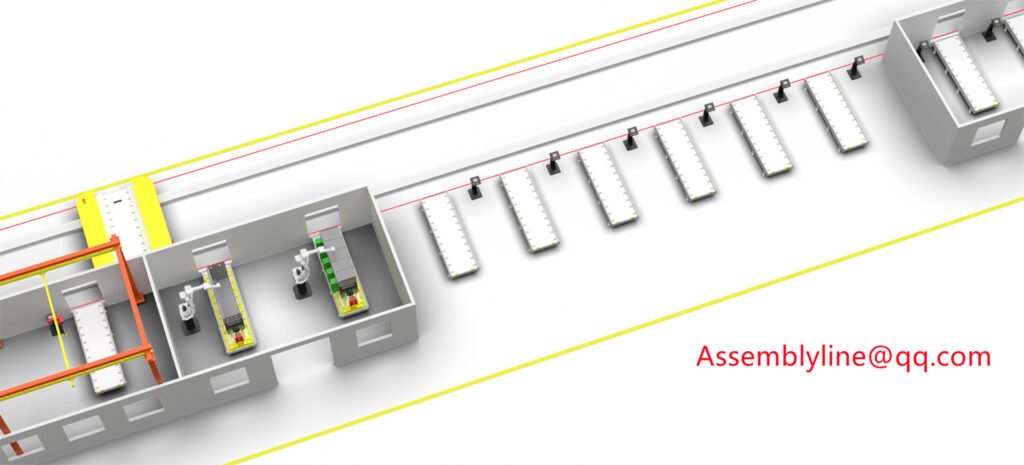

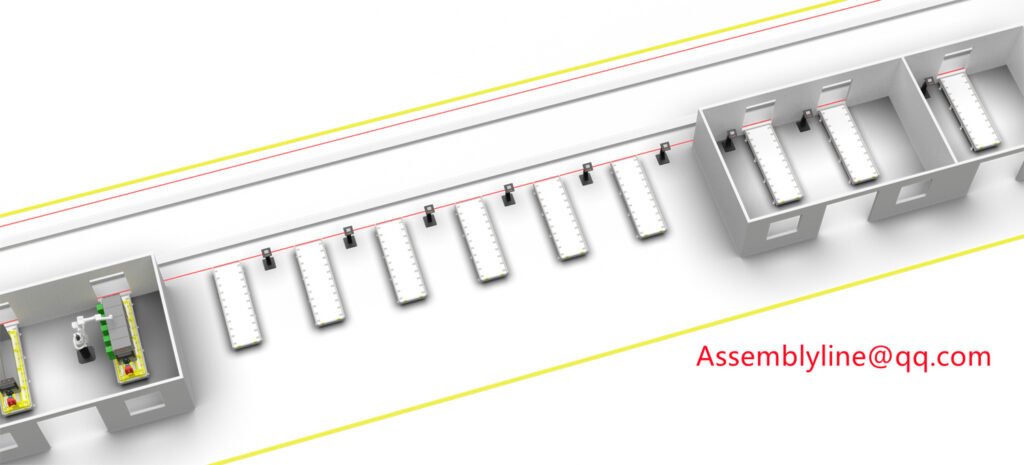

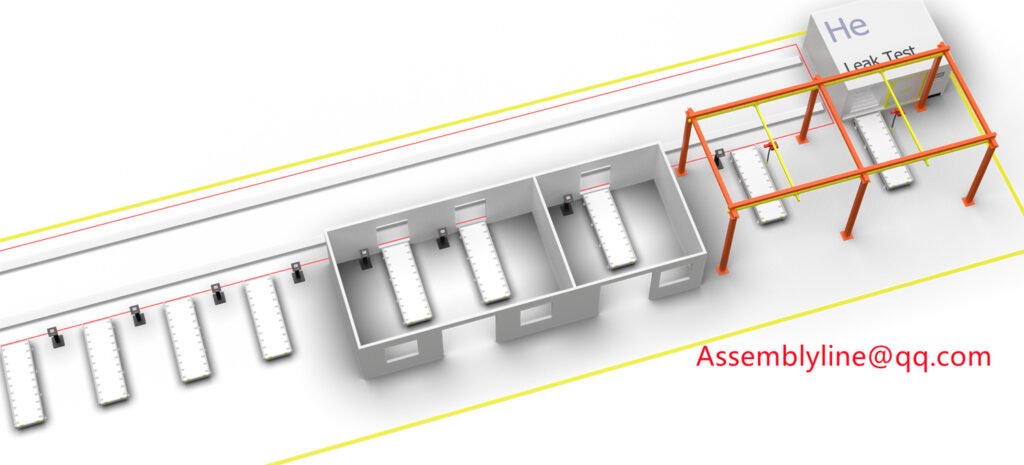

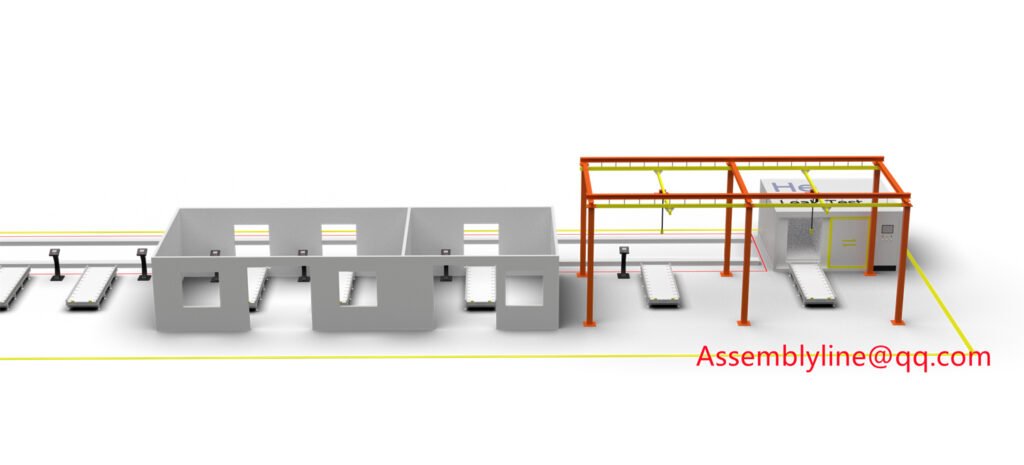

The gas chamber structure of the ring main unit (RMU) is a core component that uses SF6 (sulfur hexafluoride) gas as an insulating and arc-quenching medium, providing efficient electrical isolation and safety protection. The gas chamber structure is typically divided into two types: common chamber and unit-type. The common chamber design integrates multiple functional circuits into one gas chamber, while the unit-type provides separate gas chambers for each functional circuit to optimize space utilization and enhance safety performance. The assembly, production, and testing production line for ring main units is a highly automated system that includes the manufacturing of metal casings, the assembly of functional circuits, the installation of operating mechanisms, insulation treatment, and comprehensive performance testing. This production line achieves a fully automated production process from raw material processing to final product assembly through automated shuttle cars and customized workstation modules. In addition, the production line is equipped with a performance testing system and a control management system to ensure product quality and production efficiency.