What are the testing devices in the power switchgear production line?

In the production line of power switchgear, various testing devices are utilized to ensure the quality and safety of the products. These include power frequency withstand voltage testers for insulation verification, circuit resistance testers for checking conductive paths, insulation resistance testers for secondary circuits, relay protection testers for control functions, mechanical characteristic testers for breaker performance, comprehensive testing platforms for multiple assessments, partial discharge testing platforms for insulation integrity, RCD testers for safety compliance, and power-on test benches for functional checks. These devices collectively ensure that switchgear meets high standards before deployment.

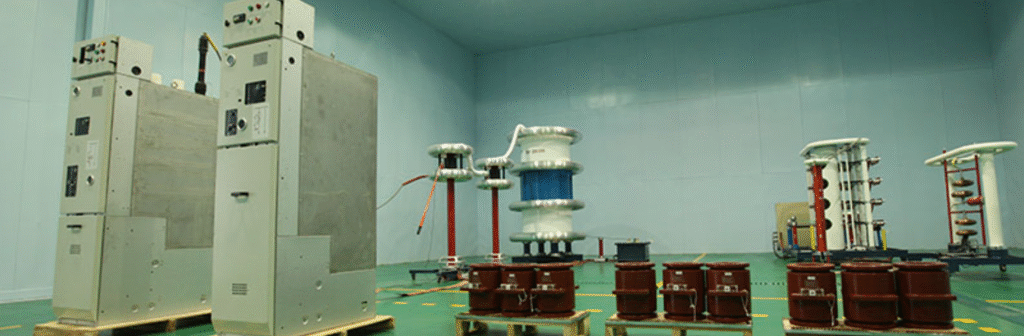

The following are common testing devices used in the production line of power switchgear, along with detailed explanations:

Primary Circuit Testing Equipment

- Power Frequency Withstand Voltage Testing Equipment: Used to perform AC withstand voltage tests on the primary circuit of switchgear to inspect its insulation performance. This ensures that the switchgear can withstand a certain level of voltage without insulation breakdown during normal operation and overvoltage conditions. During the test, voltage is applied to the primary circuit according to specified values and duration, and any discharge phenomena are observed.

- Circuit Resistance Tester: A circuit resistance tester with a current of no less than 100A is used to measure the contact resistance and conductive resistance of primary equipment such as circuit breakers in the closed state. This helps to judge the conductive performance of the equipment and identify any poor contact issues, thereby ensuring the normal transmission of current.

Secondary Circuit Testing Equipment

- Insulation Resistance Tester: An insulation resistance tester with a voltage of 500V is used to measure the insulation resistance of the auxiliary and control circuits of switchgear. By measuring the insulation resistance value, the insulation condition of the secondary circuit can be judged, preventing short circuits or leakage faults caused by insulation aging or moisture, and ensuring the safe and reliable operation of the secondary circuit.

- Relay Protection Tester: Different voltage levels are applied to the operating mechanism to verify whether it can operate normally. This ensures that the control and protection functions of the switchgear can be accurately executed under different voltage conditions, guaranteeing the safe and stable operation of the power system.

Mechanical Characteristic Testing Equipment

- Switchgear Mechanical Characteristic Tester: Used to measure parameters such as closing time, opening time, and opening/closing synchronicity of circuit breakers. These parameters are crucial for ensuring the reliable opening and closing operations of circuit breakers. Accurate measurement and analysis can determine whether the mechanical performance of the circuit breaker meets the requirements, and identify and address any potential mechanical faults in a timely manner, ensuring its rapid and accurate operation in the power system.

Comprehensive Testing Equipment

- Switchgear Comprehensive Testing Platform: Integrated with various AC and DC power sources, this platform can meet multiple testing requirements simultaneously, significantly improving work efficiency. The input power is three-phase four-wire AC 380V, and it can output power with different voltages and currents, used for comprehensive detection of switchgear, including power-on tests, operating voltage tests, closing power tests, etc.

Special Testing Equipment

- Partial Discharge Testing Platform: Comprising a double-shielded isolation transformer, a fully shielded room, line filters, high-voltage filters, and a partial discharge tester, this platform can effectively suppress interference from power networks and spatial electromagnetic waves. It accurately detects partial discharge conditions inside switchgear, allowing for the early identification of potential insulation defects and preventing equipment failures and power outages caused by partial discharges.

Other Testing Equipment

- Residual Current Device (RCD) Tester: Used to test parameters such as the residual current tripping value, tripping time, and non-tripping current of RCDs. This ensures that RCDs can reliably cut off the power supply in case of leakage, safeguarding personnel and equipment.

- Power-On Test Bench: Provides a simulated actual operating environment for switchgear, allowing for power-on tests to check whether the functions of the switchgear are normal under power-on conditions, such as indicator light display, switch operation, and the absence of abnormal heating or noise.

The following table lists the testing devices used in the power switchgear production line:

| Equipment Name | Main Function | Scope of Application |

|---|---|---|

| Power Frequency Withstand Voltage Testing Equipment | AC withstand voltage test for primary circuit | 12KV/24KV/40.5KV Solid Sealed High Voltage Switchgear, etc. |

| Circuit Resistance Tester | Measure the contact resistance and conductive resistance of primary equipment | 12KV Gas Insulated High Voltage Switchgear, etc. |

| Insulation Resistance Tester | Measure the insulation resistance of auxiliary and control circuits | Secondary circuits of various switchgear |

| Relay Protection Tester | Verify the operation of the operating mechanism | Control and protection functions of various switchgear |

| Switchgear Mechanical Characteristic Tester | Measure closing time, opening time, etc. of circuit breakers | Circuit breakers of various switchgear |

| Switchgear Comprehensive Testing Platform | Integrated with various power sources for multiple detections | Comprehensive detection of various switchgear |

| Partial Discharge Testing Platform | Detect partial discharge inside switchgear | Insulation detection of various switchgear |

| Residual Current Device (RCD) Tester | Test parameters of RCDs | Residual current devices in switchgear |

| Power-On Test Bench | Perform power-on tests to check functions | Power-on detection of various switchgear |

During the testing process of power switchgear, the following protective measures need to be taken:

Electrical Safety Protection

- Insulation Protection: Operators should wear insulating gloves, insulating shoes, and other insulating protective equipment to avoid direct contact with live parts and prevent electric shock accidents.

- Grounding Protection: Ensure that the testing equipment and the switchgear being tested are reliably grounded. The grounding wire should be securely connected, and the grounding resistance should meet the requirements to prevent leakage and static electricity accumulation.

- Voltage Level Marking: Clearly mark the voltage level and danger warning signs in the testing area to remind personnel of the high voltage danger and prevent accidental entry into live areas.

- Isolation Measures: Use safety barriers or isolation screens to separate the testing area from non-testing areas, and set up clear warning signs to prevent unauthorized personnel from entering the testing area.

Personal Protection

- Safety Helmets: All personnel entering the testing site must wear safety helmets to protect against accidental head impacts.

- Protective Eyewear: When performing operations that may produce arcs, sparks, or splashes, such as withstand voltage testing or mechanical characteristic testing, operators should wear protective eyewear to protect their eyes from injury.

- Earplugs or Earmuffs: In high-noise environments, such as during switch operations or mechanical testing, earplugs or earmuffs should be worn to protect hearing from damage.

Equipment Protection

- Overload Protection: Testing equipment should be equipped with overload protection devices that automatically cut off the power supply when the current or voltage exceeds the rated value of the equipment, protecting it from damage.

- Moisture and Dust Protection: Ensure that the storage environment for testing equipment and switchgear is dry and clean to prevent the effects of moisture and dust on the insulation and mechanical performance of the equipment.

- Equipment Securing: When performing mechanical characteristic tests or vibration tests, the equipment being tested should be securely fastened to prevent it from shifting or toppling during the test, which could cause equipment damage or personal injury.

Environmental Protection

- Good Ventilation: The testing site should have good ventilation to prevent the accumulation of harmful gases or smoke, especially during withstand voltage testing or partial discharge testing when gases may be generated that need to be promptly expelled.

- Fire Prevention Measures: The testing site should be equipped with fire extinguishers and other fire-fighting equipment to ensure that fires can be promptly extinguished. At the same time, avoid storing flammable materials in the testing area.

Emergency Measures

- First Aid Equipment: The testing site should be equipped with a first aid kit containing commonly used first aid medicines and equipment to allow for initial treatment in case of personnel injury.

- Emergency Exit Routes: Ensure that there are clear emergency exit routes at the testing site and keep them unobstructed to allow personnel to evacuate quickly in case of emergency.

- Emergency Plan: Develop a detailed emergency plan that clearly defines the procedures and responsibilities for handling emergencies such as electric shock, fire, and equipment failure. Regularly organize emergency drills to improve personnel’s emergency response capabilities.